I think its about time i converted to fully pumped. In terms of pipework, is this something which im allowed to do myself? (No gas pipe work only water) and if so, how would be the best way to do it?

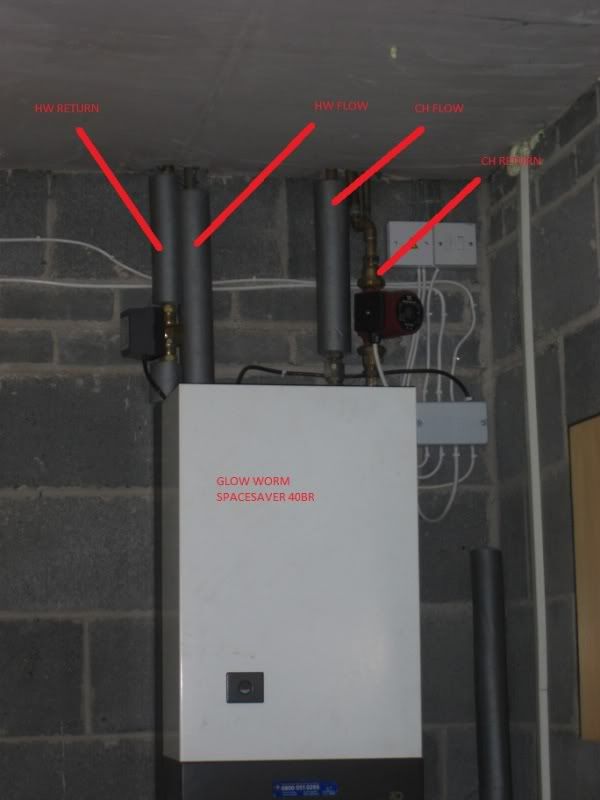

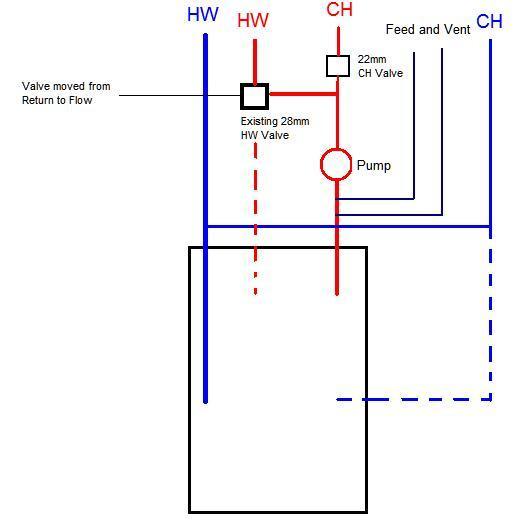

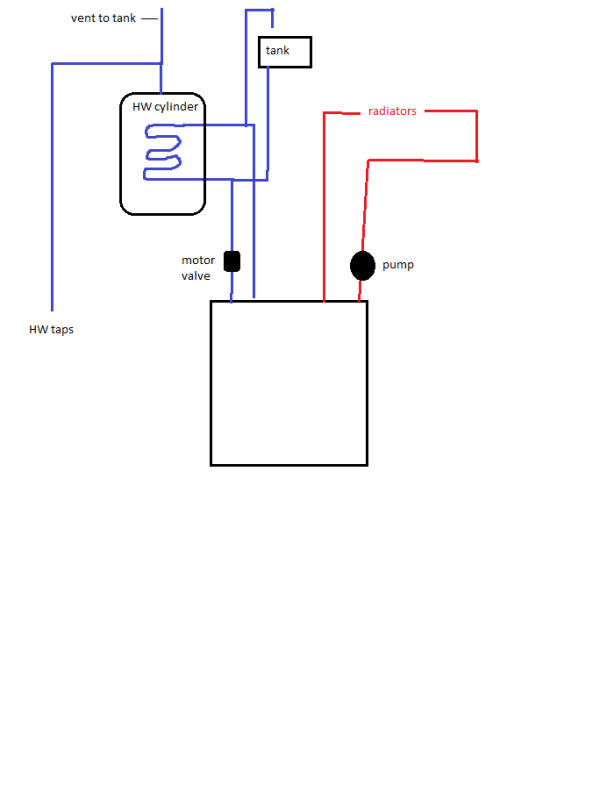

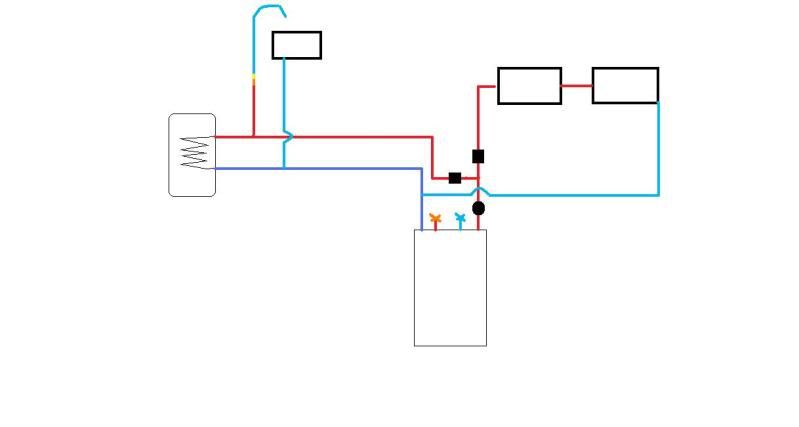

At the moment my boiler is in the garage with the flow and returns for primaries and secondaries coming straight out of the top of the boiler and into the celing (about 18 inches above the boiler). The motorised valve for the hot water is in the primary return and the CH pump is on the secondary return pipe.

So basically, how would you go about altering the pipework to be compatible with S plan? wiring wise its ok as i am an engineer and will notify. The reason im going for S plan over Y plan is because i have not got the option to pull in a new cable from the timer to the boiler and for Y plan i would need an extra wire for HW off.

At the moment my boiler is in the garage with the flow and returns for primaries and secondaries coming straight out of the top of the boiler and into the celing (about 18 inches above the boiler). The motorised valve for the hot water is in the primary return and the CH pump is on the secondary return pipe.

So basically, how would you go about altering the pipework to be compatible with S plan? wiring wise its ok as i am an engineer and will notify. The reason im going for S plan over Y plan is because i have not got the option to pull in a new cable from the timer to the boiler and for Y plan i would need an extra wire for HW off.