You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

pumping over & c plan to s plan

- Thread starter 77up

- Start date

I have just realized that there is a much simpler explanation for the pumping over when the system is running for CH only: it's the easiest path for the water to follow.Hi,

The boiler is a Mexico HE15 heat only - thus the output is 15kw.

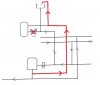

When the Valve V01 is closed, there is an open path from the pump to the vent pipe, show in red on the diagram below. The pressure loss along this route will be much lower than round the rad circuit, so water will prefer to travel this way. Result - pumping over.

Frame 3, page 12, of the installation manual gives the requirement for an Open Vented system; yours seems to break many of them, e.g pump on return not flow etc etc. I don't know how Ideal would view this if something went wrong and you claimed under Warranty. Safest to ask Ideal - installer should do this.

I'm assuming your installer hasn't registered the boiler with building control, as is mandatory per building regs; primarily because the work they've done is in contravention of building regs.

Since the work does not meet the regs the boiler warranty is also invalid. And I think it is fair to assume that since everything else is wrong, the system would not have been cleaned prior to the installation of the boiler. In fact this boiler installer is not a boiler installer.

Lucky it was a 15Kw boiler, otherwise I think we can be certain the gas pipework would be undersized, too.

The easiest way to stop pumping over if Ideal do not permit the use of a combined CF and V pipe (we don't install Ideal products so don't know) is a sealed system conversion. That way you can keep all the sludge in the boiler, pipes and radiators .

.

Since the work does not meet the regs the boiler warranty is also invalid. And I think it is fair to assume that since everything else is wrong, the system would not have been cleaned prior to the installation of the boiler. In fact this boiler installer is not a boiler installer.

Lucky it was a 15Kw boiler, otherwise I think we can be certain the gas pipework would be undersized, too.

The easiest way to stop pumping over if Ideal do not permit the use of a combined CF and V pipe (we don't install Ideal products so don't know) is a sealed system conversion. That way you can keep all the sludge in the boiler, pipes and radiators

- Joined

- 19 Jul 2007

- Messages

- 5,950

- Reaction score

- 1,144

- Country

I have just realized that there is a much simpler explanation for the pumping over when the system is running for CH only: it's the easiest path for the water to follow.

When the Valve V01 is closed, there is an open path from the pump to the vent pipe, show in red on the diagram below. The pressure loss along this route will be much lower than round the rad circuit, so water will prefer to travel this way. Result - pumping over.

View attachment 110744

Which is why the cold feed and vent should be close coupled on the pump suction.

Please ignore the previous post. I had the same thoughts as you ( D. Hailsham ), namely that the water was taking the path of least resistance - thus the pump over. Thank you for your thoughts on the matter. It is nice to have your views confirmed by someone else.

I would also agree with Simond regarding the expertise of the installer! For that reason I shall be cleaning and flushing the system prior to fitting a zone valve in line with an S plan. I shall probably combine the feed and vent pipes hoping that this will solve the pump over problem.

I would also agree with Simond regarding the expertise of the installer! For that reason I shall be cleaning and flushing the system prior to fitting a zone valve in line with an S plan. I shall probably combine the feed and vent pipes hoping that this will solve the pump over problem.

- Joined

- 10 Oct 2011

- Messages

- 16,396

- Reaction score

- 4,043

- Country

Your understanding is incorrect....S and Y plans were installed back in the 70's with myself being one of those installers..It's my understanding that the format indicated in my initial post was standard practice in the 80's and possibly into the 90's.

The system layout you have was possibly installed by a chimp..

Cut and cap the cold feed where it enters the system , re-route cold feed and tee it into open vent within roof space.

The feed and vent will still be on the wrong side of the pump.Cut and cap the cold feed where it enters the system , re-route cold feed and tee it into open vent within roof space.

- Joined

- 10 Oct 2011

- Messages

- 16,396

- Reaction score

- 4,043

- Country

The feed and vent will still be on the wrong side of the pump.

Please explain what that is meant to signify.

Yes Steelmasons, I intended to do just that to combine the feed and vent pipes. I shall refrain from going down the historical path - just in what decade the system layout that I have was deemed to be an acceptable/standard design.

As, D. Hailsham pointed out when referring to page twelve of the Mexico manual, it states clearly that the pump must be on the flow side.

Would putting the pump on the flow pipe make any difference to the problem of pump over ?? I am loath to change over at this time - not the best time of year to go without heating and it may be worth while getting an expert in to do the job. For me the easiest route would be to combine the pipes.

As, D. Hailsham pointed out when referring to page twelve of the Mexico manual, it states clearly that the pump must be on the flow side.

Would putting the pump on the flow pipe make any difference to the problem of pump over ?? I am loath to change over at this time - not the best time of year to go without heating and it may be worth while getting an expert in to do the job. For me the easiest route would be to combine the pipes.

- Joined

- 10 Oct 2011

- Messages

- 16,396

- Reaction score

- 4,043

- Country

You wouldn't be asking had you received the correct training.Please explain what that is meant to signify.

I could explain but I can't be arsed.

I've got better things to do than wasting my time trying to educate the googlers.

Last edited:

Update; feed and vent pipes have been combined and air vent fitted - no longer pumping over.

Contacted Ideal tech. team concerning the pump on the flow side, as indicated on page twelve of the manual, their reply was, that the pump could be fitted on either the return or flow side.

Contacted Ideal tech. team concerning the pump on the flow side, as indicated on page twelve of the manual, their reply was, that the pump could be fitted on either the return or flow side.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 1

- Views

- 1K

- Replies

- 1

- Views

- 1K

- Replies

- 7

- Views

- 2K