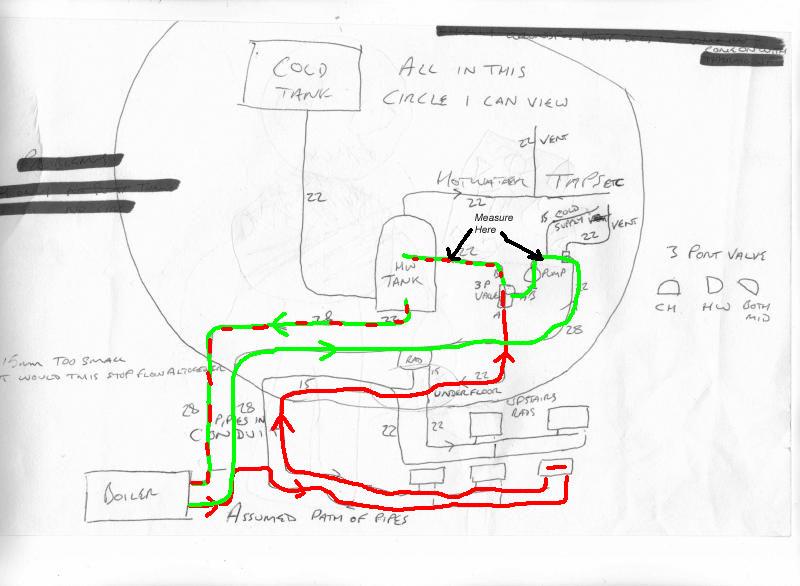

So how accurate is the new drawing.

You need to expose the pipes and produce an as fitted drawing, including the boiler connections.

My/our drawing is indicative, and nearly shows the pipes in the possible fault connections, which incidentally is a good theory.

You need to expose the pipes and produce an as fitted drawing, including the boiler connections.

My/our drawing is indicative, and nearly shows the pipes in the possible fault connections, which incidentally is a good theory.