Isolating the supply to change or work on a fuse board is a right PITA.

I don't understand the view that isolators are a waste of time. Why is it a waste of time to be able to safely work on a CU that has no power feeding it.

I have seen loads of examples of the main switch incoming cables showing far to much copper, and it makes you wary working around them.

If the supply is dead you can safely cut tails to the right size and re terminate.

You can do a far neater job pulling new cables in and organising the others when you know the board is safe.

I love it when I see an isolator if we are going to change a board, as I don't have to rely on another person/organisation to allow me to work, and I don't have to work round their schedule.

Recent example. We had to change a board so phoned the maintenance people and after the usual 'you need to speak to this department' and being kept on hold for 15 minutes you finally get to speak to somebody that knows what you are on about.

So you ask will you fit an isolator

A - No we don't do that

Q - But I need to isolate the supply

A- Well we will send someone round to pull the main fuse then come back to put it back in.

So you agree a date but they won't give you a time apart from between 8-10 am to pull and 3-5 to replace.

OK. so the day arrives and a young lad in a van with some company logo i have never heard of pulls up.

Are you from Siemens I ask.

A - Err, yes, what do you need doing

I tell him that I have booked him to pull the fuse and return to replace.

He then goes on about how much work he has to do and will not be able to come back.

Well I need to switch the power back on, will some one else return.

This lad is unsure, so I ask if he could just fit an isolator. which thankfully he did.

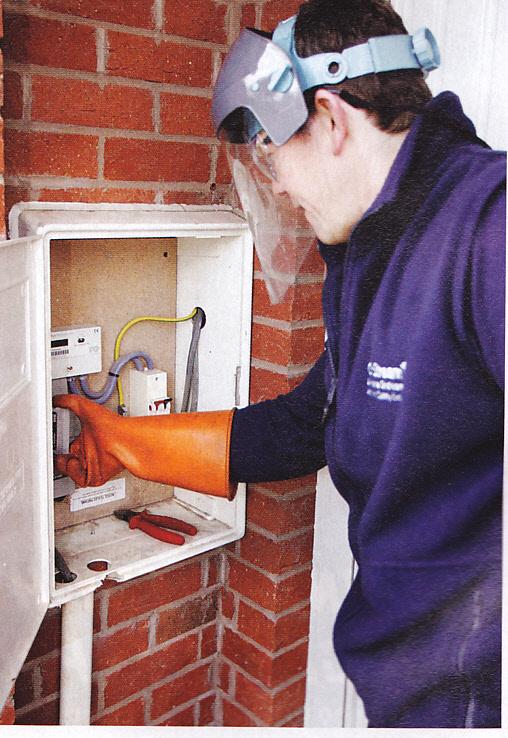

When it came to pulling the fuse I was interested how the a 'Trained' person would do this.

Procedure

Quick check on mobile phone to read a text message

Switch the CU off without asking if it was OK to turn off the supply

Cut seal (Yes it had some)

Pull out the fuse (No PPE at all , no suprise)

Took him half an hour. Stuck his sticker on to say polarity had been checked and witnessed, though no testing was done.

The only testing gear he had was a socket polarity tester, and he did not even use that.

Power up and he was gone.

A few DNO post on here. Is that the correct procedure?

There must be a better way.