This is my first time on this forum and I have a question which I seen asked many times but there has never been a clear answer.

I have a standard Y plan central heating system with a vented indirect water cylinder. The current coil doesn't heat the water quickly so I was looking to replace the coil with a plate heat exchanger.

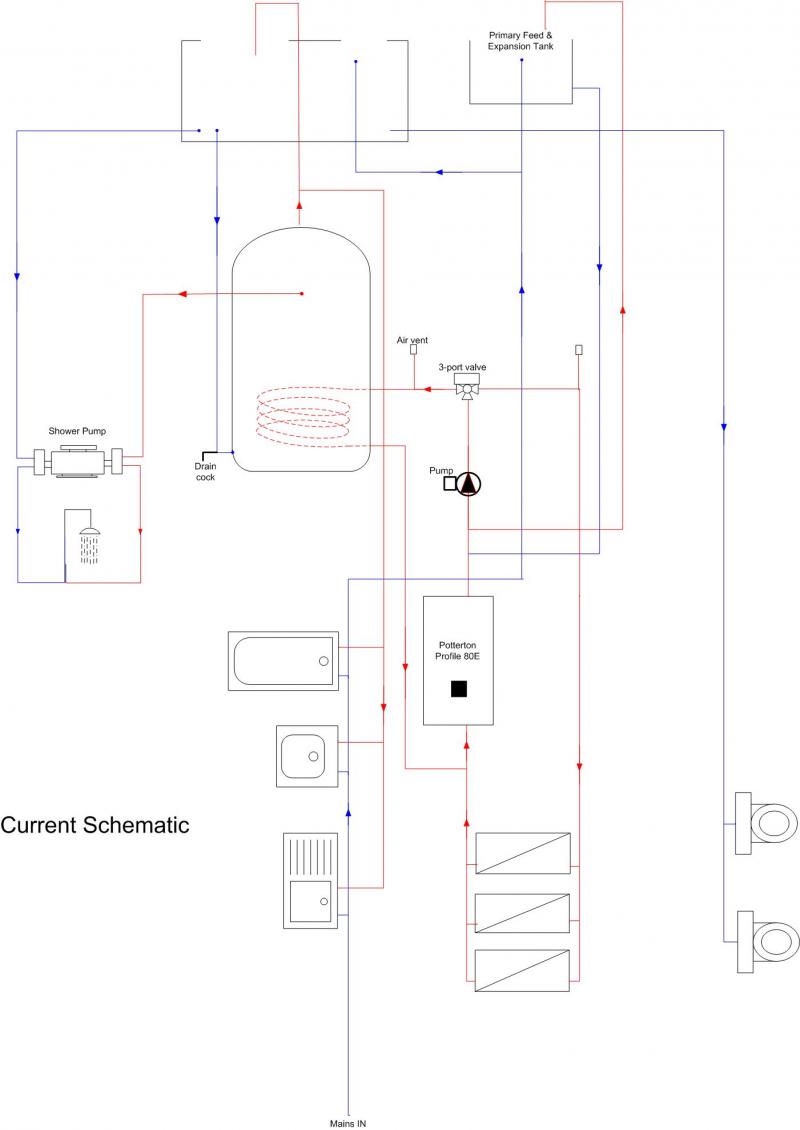

This is my current setup:

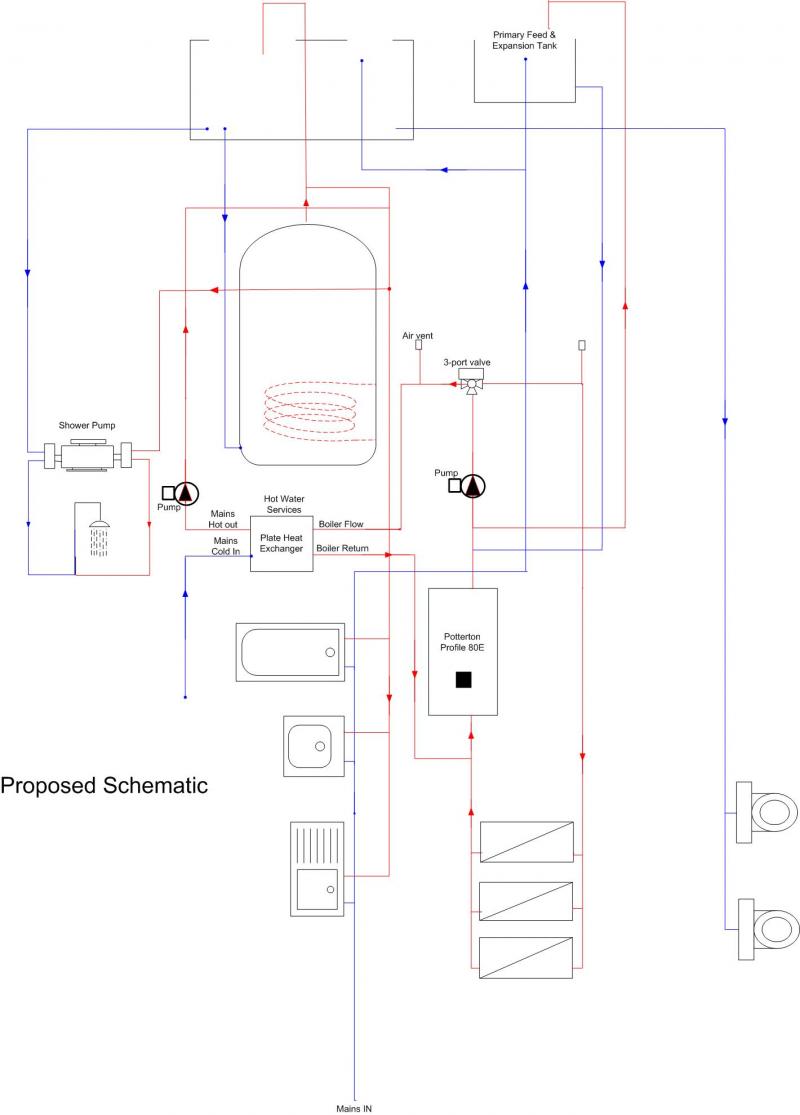

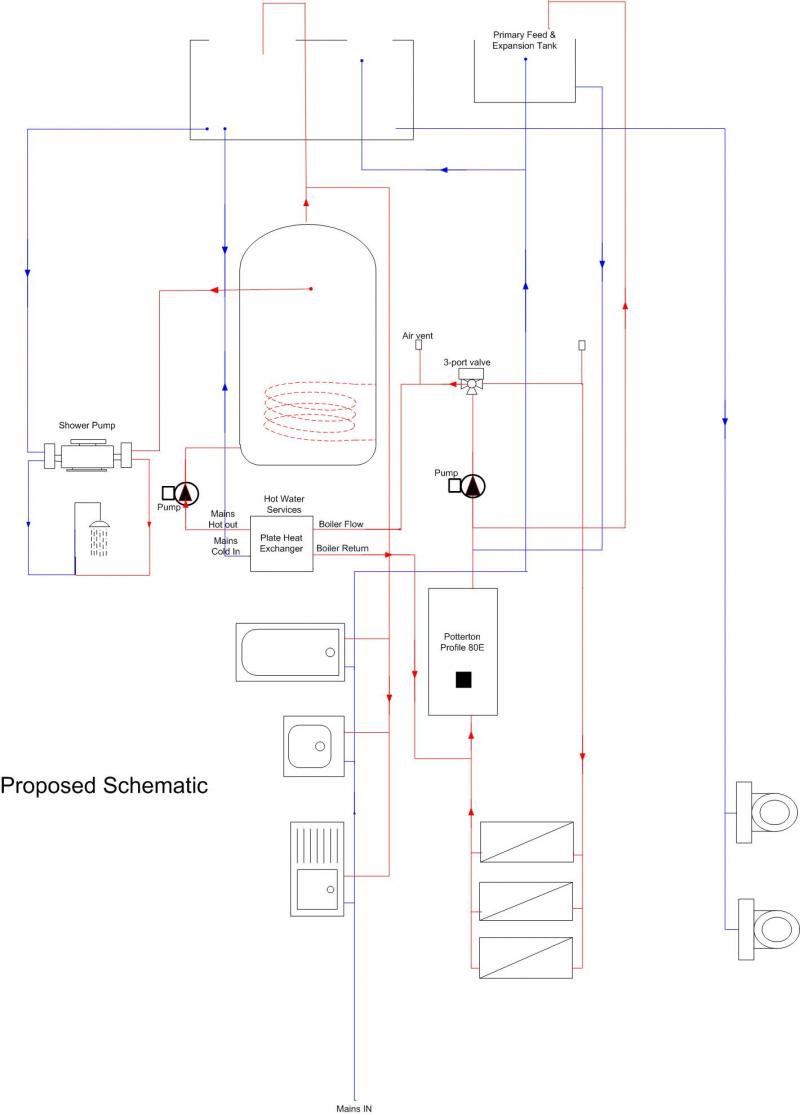

what I was looking to do is the following:

Is it possible to do this?

Can someone explain how I could reconfigure my current system to allow me to have a configuration for instant hot showers without having to replace my current boiler?

I found this link which is very close to what I would like but I can't see how to apply this to my setup.

http://www.diynot.com/forums/viewtopic.php?t=75050&start=15

Any help would be most appreciated.

I have a standard Y plan central heating system with a vented indirect water cylinder. The current coil doesn't heat the water quickly so I was looking to replace the coil with a plate heat exchanger.

This is my current setup:

what I was looking to do is the following:

Is it possible to do this?

Can someone explain how I could reconfigure my current system to allow me to have a configuration for instant hot showers without having to replace my current boiler?

I found this link which is very close to what I would like but I can't see how to apply this to my setup.

http://www.diynot.com/forums/viewtopic.php?t=75050&start=15

Any help would be most appreciated.