- Joined

- 12 May 2007

- Messages

- 292

- Reaction score

- 2

- Country

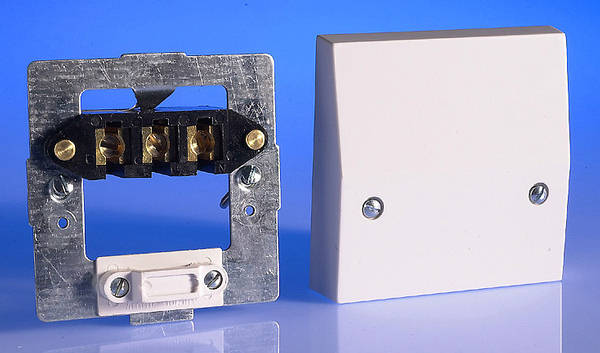

I put a standard cavity back box in for the cooker connection. I bought a volex connector and plate but notice the screw holes on the face plate are lower than central, where screw holes for back box are, is this the wrong type of back box?