Hit_It

I know how this stuff is fabricated and with the greatest respect to the guys in Blackpool I can't see how you can patent a bi-colour edge stringing. After all, woodworkers have been using them for hundreds of years. The fact that they've developed a

process to produce the stringings may be patentable - but only if they can prove to the Patent Office that it is a unique or unusual combination of technologies. My feeling is that any competent solid surface fabricator should be able to produce a banding such as this. I'm not trying to down play the skill of your fabricator - that is self-evident - but there is a huge amount of over-inflated hype in the solid surface market.

If you want alternative fabricators you could try ringing Dupont (manufacturers of Corian) for a list of authorised fabricators, or try Formica for a list of their Colourcore fabricators. There are other manufacturers of similar materials including Schock at Bamber Bridge (their parent company in Germany developed Corian for Dupont) and Wilsonart up in Co. Durham. You could also take a look at Iro on the

Irpen site - they don't sell into the domestic market in the UK, but their colour range is just as wide as Corian.

Jason

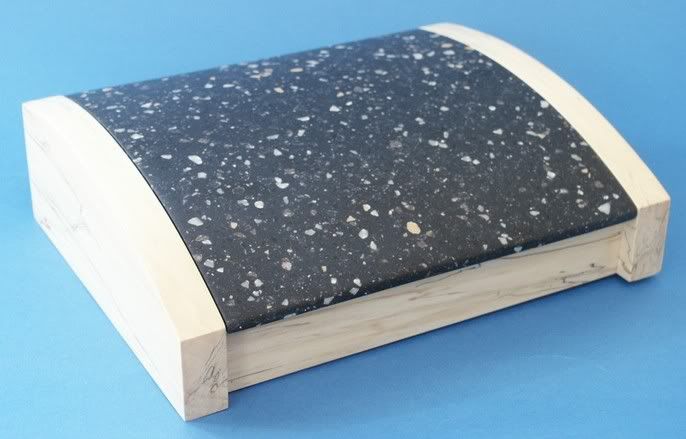

The inlay shown probably doesn't need a CNC to cut it, just an accurate panel saw. A lot of solid surface materials such as Corian, Schock, Formica Colourcore, etc. are basically acrylic resins bonded onto a wood product substrate, such as chipboard or MDF. The materials are also supplied in thin sheets down to 3mm thick in many cases and the nice thing about acrylic is that you can glue it together using a solvent cement which is not dissimilar to the stuff used for Airfix kits! That means that you can make-up chess boards in the stuff then apply them to a routed-out section in a worktop if you like (something they teach fabricators to do, BTW). The downside is that it is impossible to get a high gloss finish on it (if that is what you want) and it does have a tendency to mark if abused. Similarly burn it and you can rout-out a section and repair it almost invisibly by inlaying. A CNC is nice to have, but not strictly necessary on solid surface materials as most of them (including Corian) can be worked with conventional woodworking tools and tooling - the only difference is that hand router tooling require Delrin bearing covers to avoid marking the material. One or two manufacturers such as Dupont and Formica put major restrictions on who they will sell the raw material to - that's the

only special thing about the stuff. In commercial kitchens or bathrooms there is a good case for solid surface products on the ground of easy maintainability, but personally I'm with you on the granite worktops for domestic surfaces.

Scrit