Well I think you've already demonstrated yourself significantly better qualified than "a great many" data installers - you've asked !

IMO, a great many people installing data really haven't a clue - I've seen some real howlers. In one case, I've found at least a foot of sheath stripped back. And there really is a big difference between mains and data.

Personally, I don't get to do much cable installation - I work too slowly at it

As to types of sockets, well most use "punchdowns". Most have Krone terminals these days, buy you may come across 110 punchdowns which use a different tool (I have both in my toolbox, not used the 110 for some years). I'm not averse to punchdowns for the sockets, but I don't like monolithic patch panels (all in one piece) - I much prefer some variation of "keystone" panel which means individual sockets can be worked on without disturbing everything.

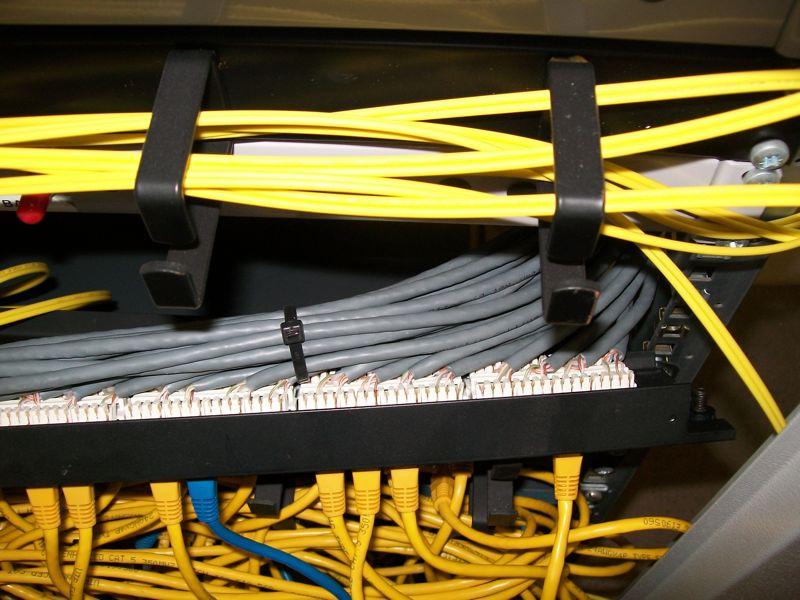

Here's a couple of shots of a panel I had to work on a while ago - we had a bad connection.

In this case, the issue was made harder by teh lack of spare cable which meant I couldn't pull the panel out any further. I always worry that you always disturb the cabling to adjacent sockets when ever you have to work on one of these.

While this is one of mine, done with Nexans HD808 connectors (the front view is partially terminated).

On these, you crimp the connectors onto the cable, then slot them into the panel. This is their newest version where the connectors slot in from the front - I don't like them that much as you have to remove the front panel to add/remove connectors whereas on the previous version you didn't. Many manufacturers have keystone options, but they tend to cost more.

I find them a lot easier to terminate initially as well - you only have to manage one cable at a time !

And for good measure, this is the only one I have to hand of how not to do it !

As to testing, well this is where it gets difficult.

You can only be certain of the result if you test, but the proper gear makes an electricians MFT seem like pocket money prices

At my last place I persuaded them to buy me an ex-rental Fluke DSP-100 set - cost something like £3.5k back in the late 90's/early 00's (they were £7k new). Just seen that there are a couple of sets on eBay at the moment and still asking £400+ ! I picked a set up myself a year or so back for around £400. These only do Cat5, not Cat5e - but they do give you a good idea of the quality of cable.

Got for Cat5e or Cat6 sets and you quickly get into the multiple £k range.

If buying something like the DSP-100 (not familiar with the others so can't comment) make sure you get either a second unit or a "Smart Remote". The DSP-100 had the option of a basic remote or a smart remote (which cost more). The difference is that the smart remote has all the testing abilities of the main unit and so can do the NEXT tests from the remote end - with a basic remote, you need to test the cable twice (once from each end).

Apart from that aspect of testing, something like this will really, really, (can't stress this enough)

really earn its keep when troubleshooting.

Take a situation I was sent to a couple of weeks ago. The customer had a cable from their main office on the ground floor up to a cabinet in the attic (2nd floor) where there was a switch and cabling to the newly refurbished rooms. They had persistent problems getting a connection to work.

Plug in the tester, hit test, and it tells me that there are two broken wires (pins 6 and 7). Go and look at the test results and it says these are at 5.3m, while I'm using a 7ft (about 2.2m) patch lead - so the first break is about 3m down the cable. One of the cheap "LED box" testers will tell you nothing but "there are two wires broken somewhere". Being out of practice I didn't think to switch to TDR mode which would probably have told me the distance to each one - in wire map mode it tells you what is open, but only the distance to the first fault.

I followed the cable but couldn't see any obvious damage - I suspect at least one staple has been put through the cable. Since the customer isn't likely to go beyond 100M, I agreed with them to just rewire both ends to use the two good pairs for an ethernet link.

Before I got the proper tester I'd have never had a clue where the problem was - only that there were broken wires.

It'll also very quickly tell you if you have split pairs which the basic testers can't do.