You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Denso Tape

- Thread starter henryb1

- Start date

Can i use Denso tape to cap over wires which will be plastered over? I dont want to use galv capping is the wire runs in ackward lines.

Thanks in advance

Any chance of a photo of these awkward lines?

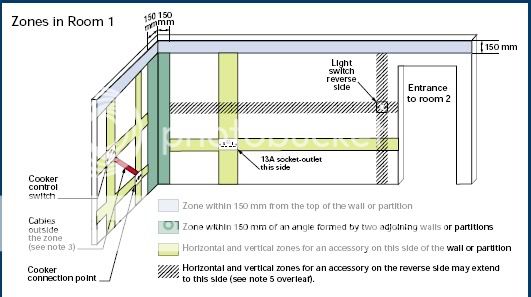

Are the cable run correctly in safe zones?

Is Denso tape like insulating tape? If so then you cannot do this.Can i use Denso tape to cap over wires which will be plastered over? I dont want to use galv capping is the wire runs in ackward lines.

Thanks in advance

If the cables will no longer be in safe zones when covered over and are still live then you must use a blanking plate. If you have disconnected the other end and the cables are no longer live and will never ever be reconnected again then you can do what you like!

- Joined

- 27 Jan 2008

- Messages

- 28,072

- Reaction score

- 3,407

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

Denso tape is often used to waterproof temporary joints however it does in the end dry out. On a buried joint in the Falklands where Denso tape was used when we ran out of proper cable joints it lasted about three years then we realised something was wrong as amps out of generator did not match amps into office complex. Lucky it snowed over night and melted snow marked the spot. So I would from that experience not use it on electric joints.

In theory there is no need to use capping on twin and earth cable however in practice to prevent the plasterer damaging the cable we normally use oval conduit or capping. The old tin capping is a problem as it is neither strong enough to protect the cable from a nail and makes the wall into "includes metallic part" so regulation 522.6.8 comes in and that in real terms means you can't use twin and earth it will need to be a cable with earthed metallic protection i.e. BS 8436 (Ali-tube) although a great cable buying it is something else as not stocked in DIY sheds so you need to buy whole reel with is expensive.

I am told although never used you can get a very heavy duty capping which will stop nails but I would say any metal capping should be earthed and that would be a pain.

Since all sockets need RCD protection anyway for straight runs in theory not need for any capping. However I found one cable the hard way in my house ran horizontal between switches this is permitted but I did not expect it, and when cutting a channel for water supply to fridge I cut through cable with hacksaw blade. And in spite of having RCD protection on all circuits, it really did give me a nasty belt. Had it been covered with tin capping likely I would have realised the wall material had changed, and likely I would not have hit the cable.

Round conduit (complying to BS EN 61386) will protect cables but when you realise how deep it has to go normally not an option. Unless the metal capping has a BS or BS EN number printed on it likely it will not comply.

Not first time same question has been asked see here

In theory there is no need to use capping on twin and earth cable however in practice to prevent the plasterer damaging the cable we normally use oval conduit or capping. The old tin capping is a problem as it is neither strong enough to protect the cable from a nail and makes the wall into "includes metallic part" so regulation 522.6.8 comes in and that in real terms means you can't use twin and earth it will need to be a cable with earthed metallic protection i.e. BS 8436 (Ali-tube) although a great cable buying it is something else as not stocked in DIY sheds so you need to buy whole reel with is expensive.

I am told although never used you can get a very heavy duty capping which will stop nails but I would say any metal capping should be earthed and that would be a pain.

Since all sockets need RCD protection anyway for straight runs in theory not need for any capping. However I found one cable the hard way in my house ran horizontal between switches this is permitted but I did not expect it, and when cutting a channel for water supply to fridge I cut through cable with hacksaw blade. And in spite of having RCD protection on all circuits, it really did give me a nasty belt. Had it been covered with tin capping likely I would have realised the wall material had changed, and likely I would not have hit the cable.

Round conduit (complying to BS EN 61386) will protect cables but when you realise how deep it has to go normally not an option. Unless the metal capping has a BS or BS EN number printed on it likely it will not comply.

Not first time same question has been asked see here

H

holmslaw

..

I get the impression from the OP that the plan is to run cables diagonally, as I can't work out what else they would mean by "wire runs in awkward lines". If that's the case, galv capping (and certainly not denso tape!) will make absolutely no difference. You'd have to employ earthed steel conduit, mechanical protection, or use a cable with an earthed metallic sheath such as SWA or FlexiShield.

Does the foil in Flexishield provide greater mechanical protection than steel capping?

Does the foil in Flexishield provide greater mechanical protection than steel capping?

Of course not, but if the manufacturer has been able to test and certify the operation of that cable with associated OCPDs, then it has little to do with mechanical protection.

I'm pretty sure galv capping hasn't been tested or certified to provide the levels of mechanical protection that would be required for concealed out-of-zone cables by BS7671, nor has it been certified as an earthed metallic covering that will cause correct operation of OCPDs.

BAS knows that (522.6.6) - he's just being awkward!

BAS knows that (522.6.6) - he's just being awkward!

I know, and he's pointed it out himself on previous occasions too, but I couldn't just let it pass that easily.

I have pointed it out, but I also reevaluate.

It's easy enough to show that the csa of capping makes it OK for a cpc - there are no tests of conformance required.

Likewise there are no specifications for mechanical protection.

So we all accept that the foil in BS 8436 cable is OK, but steel capping is not?

Where's the logic, the reasoning, the engineering basis for that?

It's easy enough to show that the csa of capping makes it OK for a cpc - there are no tests of conformance required.

Likewise there are no specifications for mechanical protection.

So we all accept that the foil in BS 8436 cable is OK, but steel capping is not?

Where's the logic, the reasoning, the engineering basis for that?

- Joined

- 27 Jan 2008

- Messages

- 28,072

- Reaction score

- 3,407

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

Properly applied denso tape will maintain its water barrier for many many years. The buried steel water pipe to my property was laid in 1950, it was wrapped in denso tape, under the tape the pipe looks like it was installed last week.

Denso tape is designed to do just that and for plumbing it is A1 but for electric cables there is really no need to cover unless there is some break in the insulation and if there is a break then it should be shrink sleeve (epoxy resin lined) not Denso tape. The 150mm cable I referred to was sinking around 100Kw into the ground by the time the fault was noticed and had it been closer to surface it could have been dangerous. Plaster thickness would not be enough to prevent some one touching a wet wall from getting a shock.

I get the impression from the OP that the plan is to run cables diagonally, as I can't work out what else they would mean by "wire runs in awkward lines". If that's the case, galv capping (and certainly not denso tape!) will make absolutely no difference. You'd have to employ earthed steel conduit, mechanical protection, or use a cable with an earthed metallic sheath such as SWA or FlexiShield.

I would agree something does not sound right. Unfortunately some people seem to think that thin metal capping will allow cables to be used outside the permitted zones. It is preferred by plasterers as it does not flex like plastic stuff, but personally I think it is dangerous as often not earthed and potentially it can transmit a fault from one small area to a very large area and so increase the chance of someone touching an effected area. I have always felt metal capping should always be earthed but not seen any earthed. I use plastic stuff.

Ali-Tube to BS 8436 Guardian, Earthshield, Flexishield, and Afumex seem great but every time I have tried only sold by the role which is expensive if you only want a few meters.

Conduit does not lend itself to having twin and earth dragged through it, and to use singles means whole run needs conduit also as with SWA trying to hide it behind plaster no easy task.

And as I have already said a RCD may stop you being killed but you still can get a nasty belt. And I would question the effectiveness of a RCD with a small child or someone who has a weak heart anyway?

But main thing Denso tape is for Plumbers not Electricians and although it has been used to seal electric boxes and do temporary repairs. I used it to stop concrete dust building up on electric box seals so the lids would not be concreted shut and wash down water would be less likely to enter box. But this was an addition not an instead, the box seals were still replaced as an when required.

It's easy enough to show that the csa of capping makes it OK for a cpc - there are no tests of conformance required.

Likewise there are no specifications for mechanical protection.

So we all accept that the foil in BS 8436 cable is OK, but steel capping is not?

Where's the logic, the reasoning, the engineering basis for that?

Personally, I wouldn't like to undertake any installation work where steel capping was to be used as a CPC.

Like you, I believe it would be more than up to the job. However, I wouldn't feel comfortable in using a product that has not has not been subjected to any particular tests or approvals, does not comply with a relevant BS standard, etc, when I know there are other alternatives out there that have undergone such testing.

With regard to mechanical protection, it is my interpretation that such protection should be at least strong enough to prevent the ingress of nails, screws, and other fixings commonly used in walls. We all know how easy it is to bang a nail through galv capping, so in my eyes it fails more or less straight away to provide adequate protection.

It may provide a CPC of suitable CSA, but at the same time, it may be difficult to use in practice. It'd probably have to be earthed via a ring crimp bolted through the capping, but it many cases it would be near impossible for this to remain accessible for inspection. Granted there would be similar issues for SWA buried in a wall, but it's still worthy of mention.

So we all accept that the foil in BS 8436 cable is OK, but steel capping is not?

Where's the logic, the reasoning, the engineering basis for that?

The capping would not have to actually serve as the CPC, but it would have to satisfy all the requirements demanded of a CPC.

Size is not the issue.

Meeting the requirements for preserving the electrical continuity throughout the life of the circuit is the problem, as I'm sure you well know, you devil's advocate, you.

As capping is a temporary measure to protect cable sheaths from trowels - and once the plastering is done the capping is pretty much redundant - unless you go to exceptional lengths to form joints that comply with reg 526.3 you can't rely on such capping to meet the requirements of 522.6.6 (i), which is written to mean (quite clearly) a cable construction which incorporates a metallic sheath, screen or armour.

Bit of a snag here.

The old memory has gone wonky.

I thought that 522.6.6 required the mechanical protection option to resist penetration by nails etc, not prevent it. Given that, it would have been relevant to consider what level of resistance was considered adequate, and as, when complying with 522.6.6 (i), a bit of foil or a thin layer of copper is OK, so should capping have been.

But it cannot seriously be said to prevent nails going through.

There's still a valid discussion about what would prevent penetration, but none about capping being a possibility - it prevents penetration by nails etc about as well as a coat made of a single sheet of newspaper prevents rain getting through.

Talking of coats, has anyone seen mine.....

The old memory has gone wonky.

I thought that 522.6.6 required the mechanical protection option to resist penetration by nails etc, not prevent it. Given that, it would have been relevant to consider what level of resistance was considered adequate, and as, when complying with 522.6.6 (i), a bit of foil or a thin layer of copper is OK, so should capping have been.

But it cannot seriously be said to prevent nails going through.

There's still a valid discussion about what would prevent penetration, but none about capping being a possibility - it prevents penetration by nails etc about as well as a coat made of a single sheet of newspaper prevents rain getting through.

Talking of coats, has anyone seen mine.....

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 26

- Views

- 25K