Hello,

I have been told by JobAndKnock how to create a Router Table which I have done and so far its gone really well. The original post can be found here:

https://www.diynot.com/diy/threads/routing-routers-and-angles.470222/

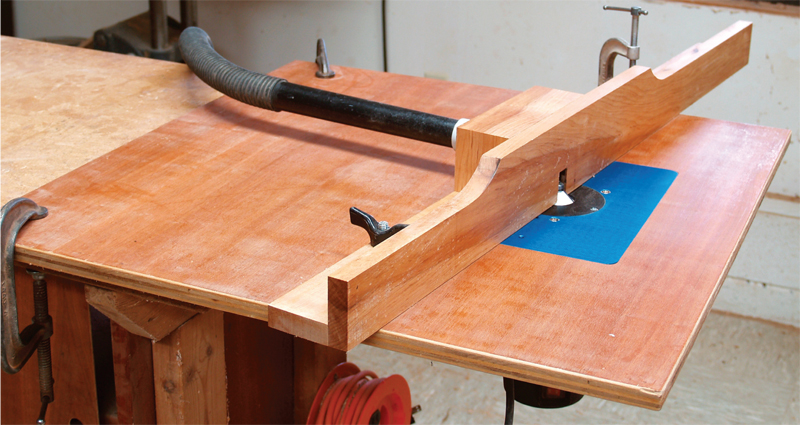

Now I have made something similar but not the same however I am a little bit confused regarding the fence.

Where does this need to go in relation to the bit? Does it need to sit in line with the bit or behind it?

I am thinking in line with the middle but I thought it best to ask before having to faff around and keep taking it apart and putting it back together.

Everything I look at on Google seems to have a gap in the fence where the bit is but I cant see if the fence is behind or in front of the fence.

Thanks

James

I have been told by JobAndKnock how to create a Router Table which I have done and so far its gone really well. The original post can be found here:

https://www.diynot.com/diy/threads/routing-routers-and-angles.470222/

Now I have made something similar but not the same however I am a little bit confused regarding the fence.

Where does this need to go in relation to the bit? Does it need to sit in line with the bit or behind it?

I am thinking in line with the middle but I thought it best to ask before having to faff around and keep taking it apart and putting it back together.

Everything I look at on Google seems to have a gap in the fence where the bit is but I cant see if the fence is behind or in front of the fence.

Thanks

James