Hey guys.

I have an outside tap kits with a self cutting tap kit. Its been installed for some years.

For a year it was fine and worked well.

But for some reason now water just trickles.

I find that as i turn the self cutting tap i hear the hiss of water passing through, it gets higher as i turn it, then suddenly shuts.

Could this be the copper "flap" it creates when doing the pearcing?

If so can i remove it to take the copper bit out and put the tap back on?

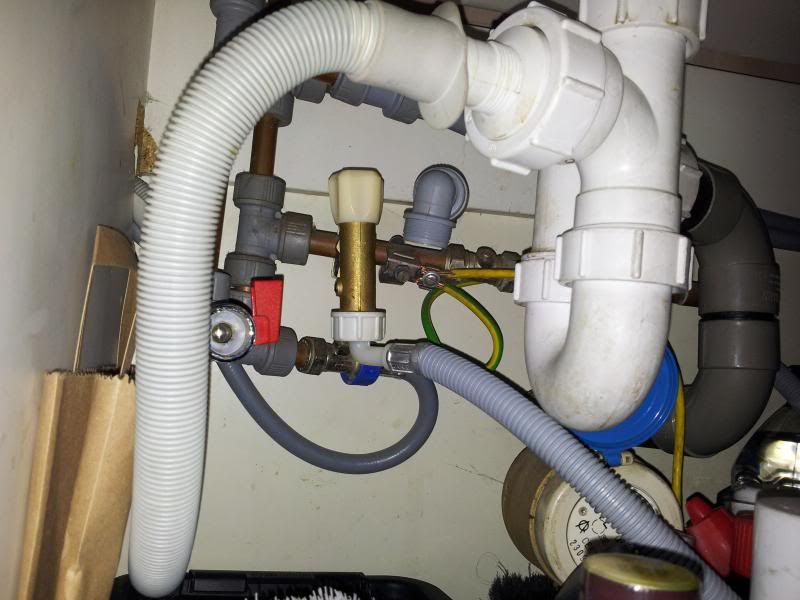

Here is the setup under the sink:

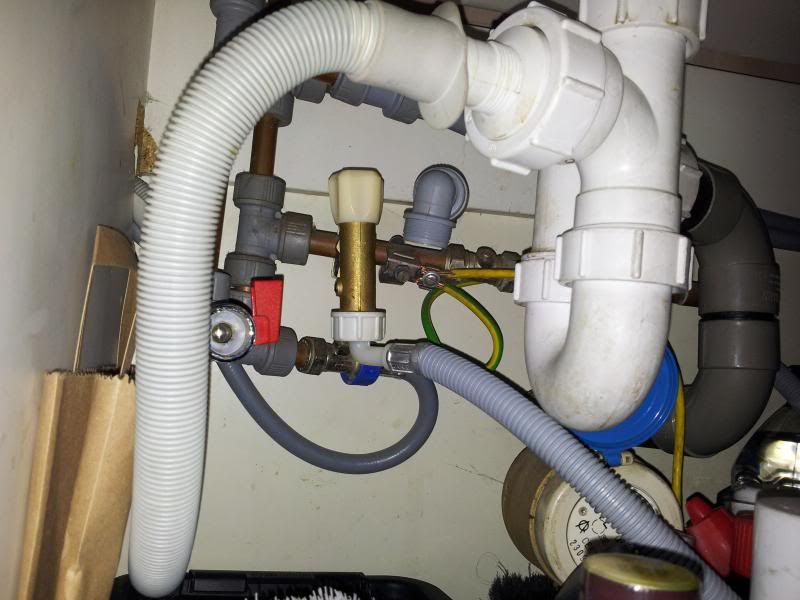

Does anyone know what this little screw does?

Thanks

I have an outside tap kits with a self cutting tap kit. Its been installed for some years.

For a year it was fine and worked well.

But for some reason now water just trickles.

I find that as i turn the self cutting tap i hear the hiss of water passing through, it gets higher as i turn it, then suddenly shuts.

Could this be the copper "flap" it creates when doing the pearcing?

If so can i remove it to take the copper bit out and put the tap back on?

Here is the setup under the sink:

Does anyone know what this little screw does?

Thanks