The manual says:d.2 is the minimum time that the boiler will wait after cycling off before cycling back on again. There is also a required minimum temperature drop. Once both the d.2 time and the temperature drop have been reached then the burners come back on if still required.

From observations and what's written in the manual, it's the MAX time (not minimum!) that the boiler will wait before cycling

d. 1 Water pump over run time for heating mode 2 - 60 min (factory setting: 5 min)

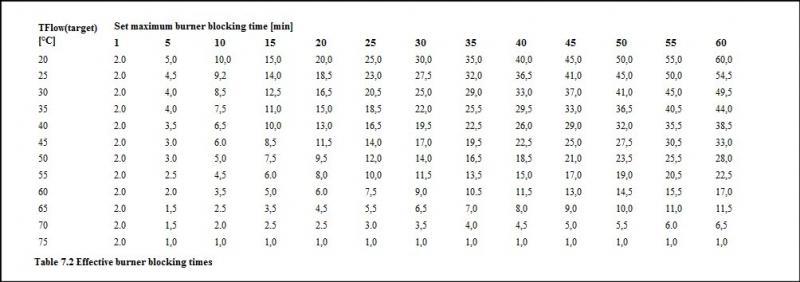

d. 2 Max. burner anti cycling period at 20 °C Flow temperature 2 - 60 min (factory setting: 20 min

Could ianniann be confusing "min" meaning minimum with "min" meaning minutes?