Hi everyone

Currently refitting the facing of a dormer. It was a cowboy job 20 years ago but in fairness has just about lasted. I’ve ripped the previous sheathing off which was plasterboard…it’s being replaced with ply. The plan was as follows:

Ply

Breathable membrane (tyvek housewrap)

Battens

Upvc cladding.

However, I’ve just realised that the existing one didn’t have battens and so if I were to use them the facing would stick out past the fascia boards. I really don’t want to mess with those as it means redoing the roof, or at least the edges?

How essential is it to have the battens. Appreciate they allow the ply to breathe but if a breather membrane is on is that not enough? What are my options here?

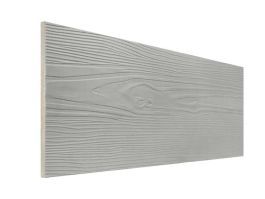

Attached a pic of it helps.

Thanks all!

Currently refitting the facing of a dormer. It was a cowboy job 20 years ago but in fairness has just about lasted. I’ve ripped the previous sheathing off which was plasterboard…it’s being replaced with ply. The plan was as follows:

Ply

Breathable membrane (tyvek housewrap)

Battens

Upvc cladding.

However, I’ve just realised that the existing one didn’t have battens and so if I were to use them the facing would stick out past the fascia boards. I really don’t want to mess with those as it means redoing the roof, or at least the edges?

How essential is it to have the battens. Appreciate they allow the ply to breathe but if a breather membrane is on is that not enough? What are my options here?

Attached a pic of it helps.

Thanks all!