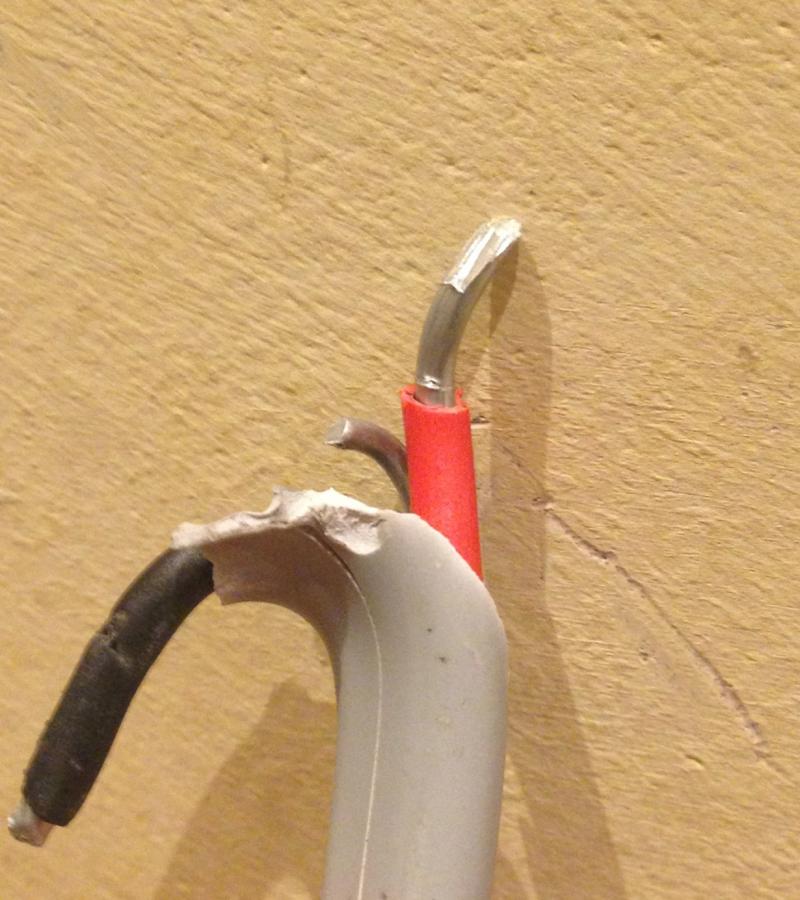

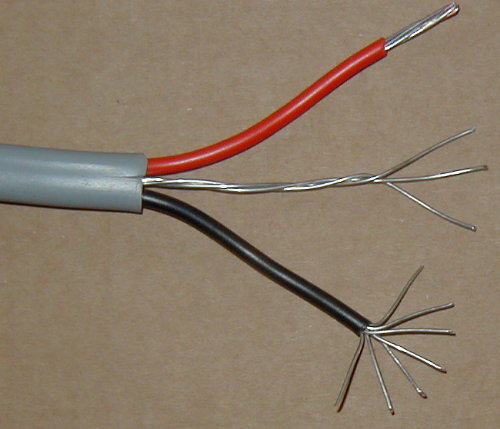

That would be 7/.029 then - It was the only standard size T&E with a 3-strand earth.Probably, cable was multi stranded cable with the CPC made up of 3 strands.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Earth-less Sockets!!!

- Thread starter eveares

- Start date

And diving into my U.K. photo archive, here's 7/.029 with tinned copper strands:

What purpose would it serve? It might be more appropriate to ask why they were ever tinned. If they had been steel, I could have understood.Just had a thought, why are most modern t&e cables not tinned any more?

Kind Regards, John

AIUI tinning is mostly to prevent oxidation, so makes sense in harsh environments, but if you need to tin copper to protect it in your house, you've got bigger issues to deal with

That was my point.AIUI tinning is mostly to prevent oxidation, so makes sense in harsh environments, but if you need to tin copper to protect it in your house, you've got bigger issues to deal with

Kind Regards, John

In the days when houses were heated by coal fires there were sufficient sulfur compounds in the air to tarnish copper quite rapidly.

If they are buried and the cables are not going to move a great deal, I would squirt some silicone around the cable entry.Also tried to get fit a 20mm open grommet where the cables enter the back box as it was missing, but the knock out where the cables enter was some size less than 20mm and the cables feeding it after all are buried in a solid stone wall so are unlikely to move.

Last edited:

The cables aren't going to move about at all.

I would consider how long they had been there already, examine how much damage has already occurred to them, and use those to inform my decision on whether I needed to retrofit protection to them.

I would consider how long they had been there already, examine how much damage has already occurred to them, and use those to inform my decision on whether I needed to retrofit protection to them.

The cables are likely to move if the socket to which they are connected is removed and replaced.The cables aren't going to move about at all.

The cables are likely to move if the socket to which they are connected is removed and replaced.

True, but it's a tight fit - not sure what's best, to cut the grommet down or to use silicon? There are two 7/.029 cables coming into the back box through a hole less than 20mm in diameter.

Personally I'd cut the grommet down, thus avoiding any problems of incompatibility between the silicone and the cable sheath. Some silicones give off acetic acid as they cure, which, trapped in a backbox, might cause tarnishing of the contacts in the socket.

Ok, I will try next time I open the socket up. Would I glue the grommet back together before fitting it?? It was a tight fit as it was getting the two cables through the grommet in the first place. FYI, the hole size where the cables enter is about 1/2" inch with the cables only just fitting through.

As you are implying, from what you have described, I think you will probably struggle to get the grommet in. If you are going to try, I think my personal inclination would probably be not to attempt to glue it back together.Ok, I will try next time I open the socket up. Would I glue the grommet back together before fitting it?? It was a tight fit as it was getting the two cables through the grommet in the first place. FYI, the hole size where the cables enter is about 1/2" inch with the cables only just fitting through.

If you feel you must do something, how about some of that flexible/cuttable 'grommet strip'?

There are some grades of silicone, designed for electrical use, that do not give off acetic acid vapour during curing. Although it wouldn't matter for what you're doing, as I have discovered to my cost, most 'ordinary' silicone sealant (that which does give off acetic acid vapour) can remain quite (electrically) conductive for several days until it is fully cured!

Kind Regards, John

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local