Here is an exercise in logic and random theory. If you decide to find a fault by cutting the cable, (or just a fault in a Ring Final) is the centre the best place to make the first cut?

Would it be better to first cut at a quarter or a third the distance. You may be lucky and find the fault on the short side. If not - have you lost anything? Which method would result in the fewest number of cuts needed to find the fault?

OK, it's all starting to come back to me now! Back in the 70's, of course, I had to tackle the problem on the basis of theory and manual analysis. Today, I have the luxury of being able to do simulations (something I would have given a king’s ransom for back then!) ....

I have very quickly undertaken some simulations (and therefore can't yet guarantee that I've got it all right!). One of the things it reminds me (as previously mentioned) is how important is the degree of precision one seeks (i.e. how short a length of cable one wants to ‘narrow down to’).

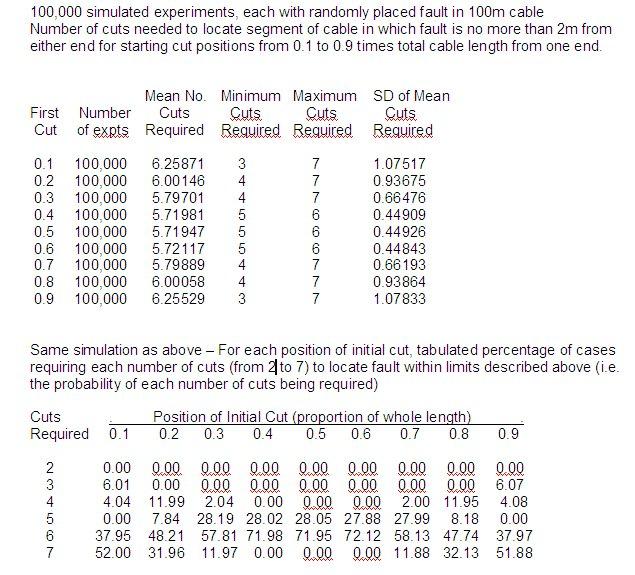

Anyway, I’ve simulated 100,000 instances of what I think is a realistic situation - a fault occurring at a random point along the length of a 100m cable and, for each of those 100,000 instances, have determined how many cuts one would have to make in order to locate the segment of cable within which the fault was no more than 2m from either end. I have repeated this exercise for a range of positions for the first cut, ranging from 0.1 to 0.9 times the length of the cable from one end (given the symmetry of the situation, I needn't have gone beyond 0.5, but I didn't twig that until after I'd done it

). The results are summarised here:

In keeping with my vague recollections from all those decades ago, the answer is ‘complicated’, but what you implied seems to be qualitatively not far off, in that (probably contrary to most people’s intuition) it does not make ‘all that much difference’ where one makes one’s first cut. As you’ll see, in my simulation, the average number of cuts required did get progressively less as the starting point got closer to the middle, but the difference was only between an average of 5.72 cuts if one started at the “50% point” (i.e.middle) and an average of 6.26 cuts if one started at the “10% point” (i.e. near one end). Correspondingly, if one starts close to the middle, one never needs more than 6 cuts, but the need for a 7th becomes progressively more likely as the starting point moves away from the mid-point – getting up to a 52% probability that the 7th will be needed if one starts at the 10% point. It appears that (at least with the parameters I’m using) one would never need more than 7 cuts if one’s first cut is anywhere between the 10% and 50% points.

In the other direction, if one starts near the middle, one will never get the answer (with required precision) with less than 5 cuts, whereas one stands a chance of getting an answer with only 3 or 4 cuts if one’s initial cut is only 10% from one end – so it’s really ‘horses for courses’, depending upon one’s attitude to gambling!

I am ‘surprised’ by my simulations appearing to indicate that that, if one starts 10% from one end, one will never need 5 cuts – one may need 3, 4, 6 or 7 cuts, but never 5! Despite searching, I haven’t yet found any flaw in my simulation to explain that, so maybe it’s just a quirk of the numbers – I’ll be investigating that (and re-checking my simulation code!) further!

Hope that's of some interest, and I hope I haven't got it all wrong (wouldn't be the first time!).

Kind Regards, John