I need to hang a Fire Door and it needs to comply with latest Fire regulations.

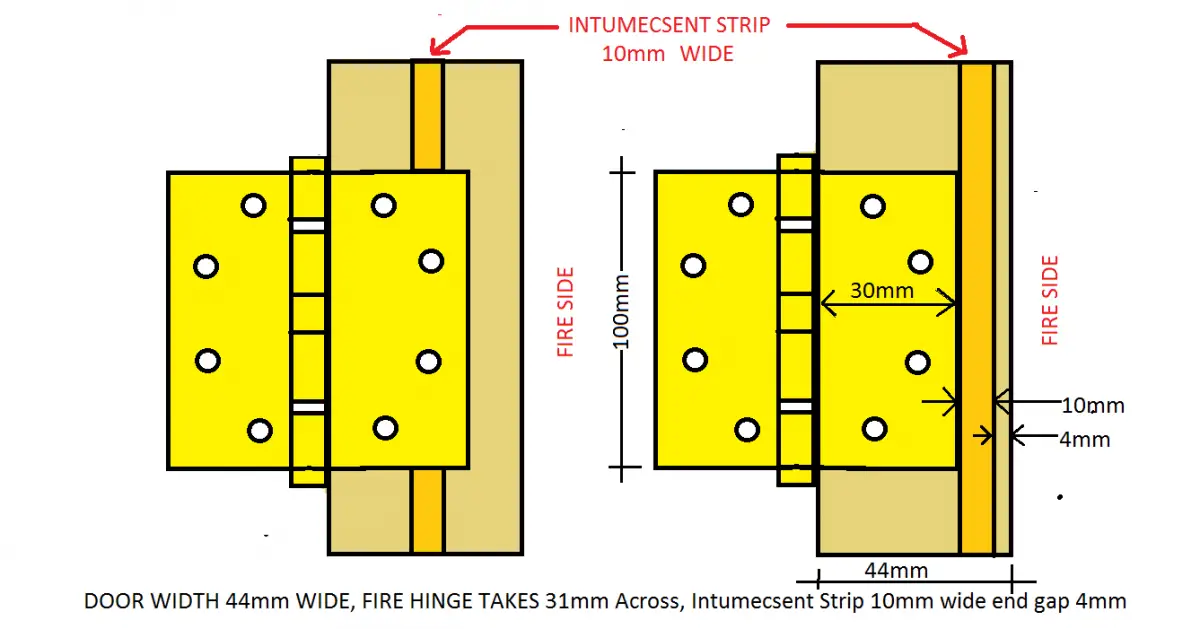

I am stuck with where to route for 10mm wide Intumescent Strip, if I route in the middle of the door, 3 Fire Door hinges will pass over the strip, which could cause smoke to pass through.

If I just miss the hinge, which is 30mm wide, and then route 10mm channel for the strip, this leaves only a 4mm wall towards the Fire side (Kitchen)

Question is is this likely to cause problem when it is this close to the fire side, if it is in the middle and hinges cover it, this may breach smoke barrier.

Please see my diagram to show you what I mean.

Please kindly let me know your best views.

With regards and thanks in advance.

mike

I am stuck with where to route for 10mm wide Intumescent Strip, if I route in the middle of the door, 3 Fire Door hinges will pass over the strip, which could cause smoke to pass through.

If I just miss the hinge, which is 30mm wide, and then route 10mm channel for the strip, this leaves only a 4mm wall towards the Fire side (Kitchen)

Question is is this likely to cause problem when it is this close to the fire side, if it is in the middle and hinges cover it, this may breach smoke barrier.

Please see my diagram to show you what I mean.

Please kindly let me know your best views.

With regards and thanks in advance.

mike