Hi. For years, my parents have had this socket in their utility room. The screws are round-headed and don't allow the plugs to be fully inserted. Apart from having to jiggle the plug occasionally, it didn't bother them.

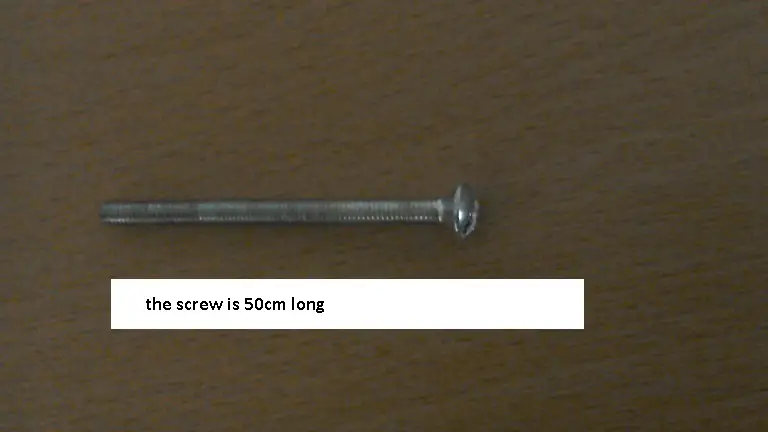

It bothered me, though, so I intended to replace the screws. I took one out but now find that it won't go back – it seems like there's just fresh air behind the plate, nothing to bite into. Can anyone suggest what has happened here (i.e. why were inappropriate screws used) and how best to fix it?

Many thanks for any advice offered.

It bothered me, though, so I intended to replace the screws. I took one out but now find that it won't go back – it seems like there's just fresh air behind the plate, nothing to bite into. Can anyone suggest what has happened here (i.e. why were inappropriate screws used) and how best to fix it?

Many thanks for any advice offered.