Hi

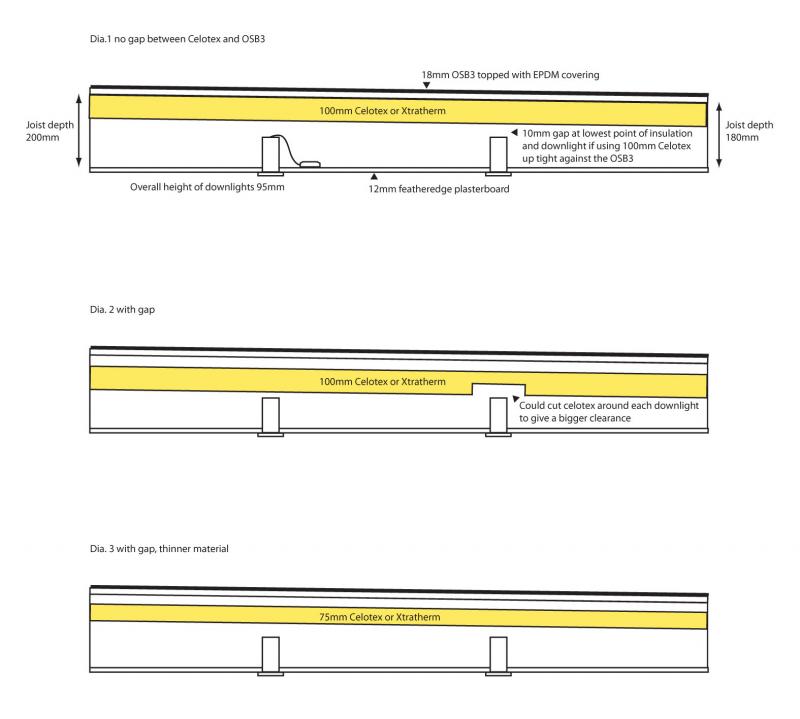

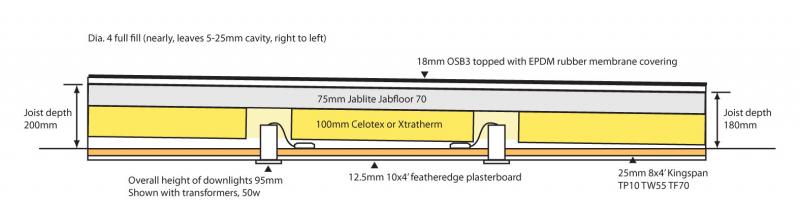

I have an extension which is my kitchen, it has a flat roof which has been covered in EPDM, having had all the light wiring done I'm just about to insulate using Celotex or Xtratherm 1200x2400x100mm (3 boards required) between the joists, once this has being done I was going to put up 1200x3050x12 featheredge plasterboard (again 3 required) skrim, fill and paint.

Is there anything else I need to do i.e. allow gaps top and bottom of the Celotex or can I push it up to the underlying boards, do I need a vapour barrier etc or can I just put it up as described, is 100mm sufficient/too thick?

I have down lights going in once completed so need to clear them height wise.

Any help/advice greatly appreciated.

I have an extension which is my kitchen, it has a flat roof which has been covered in EPDM, having had all the light wiring done I'm just about to insulate using Celotex or Xtratherm 1200x2400x100mm (3 boards required) between the joists, once this has being done I was going to put up 1200x3050x12 featheredge plasterboard (again 3 required) skrim, fill and paint.

Is there anything else I need to do i.e. allow gaps top and bottom of the Celotex or can I push it up to the underlying boards, do I need a vapour barrier etc or can I just put it up as described, is 100mm sufficient/too thick?

I have down lights going in once completed so need to clear them height wise.

Any help/advice greatly appreciated.