Hello everyone,

This is my first post after reading a few threads on these forums, courtesy of a popular search engine's results for my query terms.

I'm looking to build a carport structure.

Approximate total area being 2.6 meters wide by 10 meters long.

Maximum height over property roof tiles less than 3 meters.

Eaves height approximately 2.4 meters.

So within constraints to not requite planning permission.

I'd prefer not to attach to the property walls as like the few cranked posts with bespoke carport designs. However, I don't completely object to some tie-ins if necessary.

Had experience with a lean-to design before and it was stifling hot in warmer weather and with cooking having no where else to vent from the kitchen. This design reaches above the gutter (allowing access for clearing debris), and being just above the top cement line of the first hip tile. Hot air should be able to vent up and out without too much restriction.

The property eaves come forward as does the facia and guttering, hence the gap between the wall and the nearest line of 'posts'.

The roof being:

Either 10 mm twin wall or 16mm triple wall polycarbonate roofing sheets, probably 700mm centres if 10mm, maybe wider if the later.

Snap down glazing bars atop ~50mm wide x ~50-75 mm high/thick treated wooden 'rafters'.

Around about a 10° slope (17.6 cm in 100 cm) per recommendations (5° min, pref. 10°).

Under structure:

I was considering using aluminium 6082 T6 (no rust/rot and light weight) 48.3mm (4.4mm) scaffold tubes to construct the entire framework with either KeeKlamp-style fittings (like the path railings and cycle blockers in public footpaths) or some other scaffold support clamps. Then using double-sided fixing brackets (look a bit like the Greek letter omega) to fix the wooden 'rafters' to.

Vertical 'posts' ~2 meters spanning (away from property wall), and 1.85 meters apart (fence panel + 1 inch for concrete post).

Concrete footings (~30 cm x ~30 cm x ~60 cm deep) poured and levelled, with 'railing' baseplates (2 hex screws, 2 bolt down holes) being used to support the upright 'posts'. The baseplates seem like they are advised for climbing frames as well as railings, so I'd expect them to be pretty strong.

Double-sided fixing brackets attached to the (4) tubes that run lengthways atop the angled pieces.

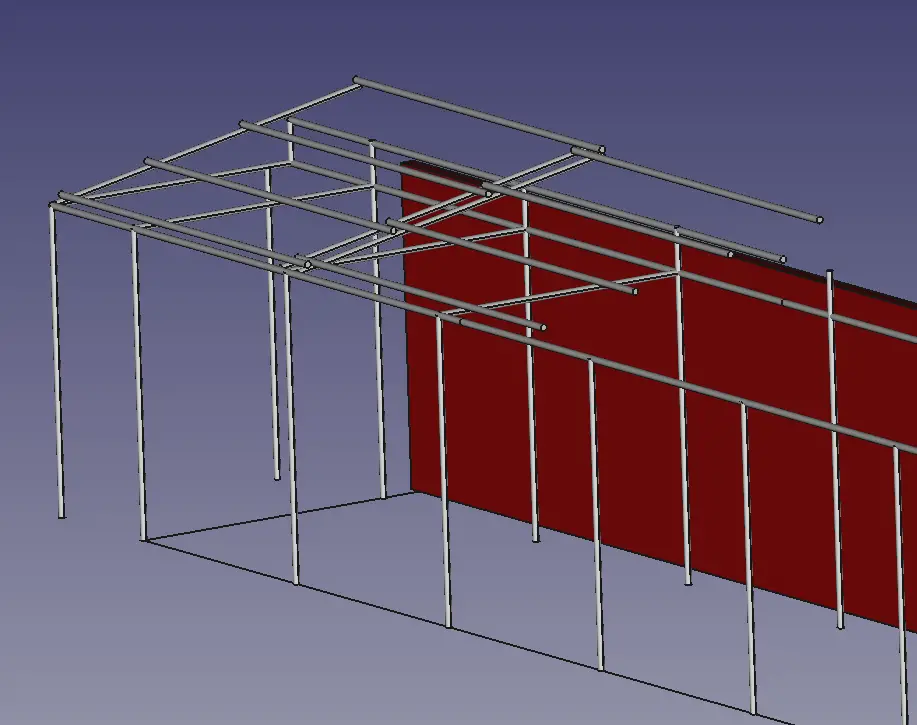

A very dirty representation courtesy of my limited time in FreeCAD.

Am I utterly mad? Is this a workable project?

I'd prefer not to use wood as it needs treating and more long-term care.

Aluminium seems preferable, but is it strong enough? I haven't worked with the stuff, but how much does a 2 meter 48mm Al tube bend?

Whilst a 20 ft /6 meter Al tube is only 10 kg, I think it's rather unwieldy. I could do 6 m and 5 m lengths, joined and cut to absolute size, but I am considering working with 3 meter length exclusively and offsetting with adding additional bracings and/or 'joiner' couplings.

Thanks for suggestions, comments and any feedback.

This is my first post after reading a few threads on these forums, courtesy of a popular search engine's results for my query terms.

I'm looking to build a carport structure.

Approximate total area being 2.6 meters wide by 10 meters long.

Maximum height over property roof tiles less than 3 meters.

Eaves height approximately 2.4 meters.

So within constraints to not requite planning permission.

I'd prefer not to attach to the property walls as like the few cranked posts with bespoke carport designs. However, I don't completely object to some tie-ins if necessary.

Had experience with a lean-to design before and it was stifling hot in warmer weather and with cooking having no where else to vent from the kitchen. This design reaches above the gutter (allowing access for clearing debris), and being just above the top cement line of the first hip tile. Hot air should be able to vent up and out without too much restriction.

The property eaves come forward as does the facia and guttering, hence the gap between the wall and the nearest line of 'posts'.

The roof being:

Either 10 mm twin wall or 16mm triple wall polycarbonate roofing sheets, probably 700mm centres if 10mm, maybe wider if the later.

Snap down glazing bars atop ~50mm wide x ~50-75 mm high/thick treated wooden 'rafters'.

Around about a 10° slope (17.6 cm in 100 cm) per recommendations (5° min, pref. 10°).

Under structure:

I was considering using aluminium 6082 T6 (no rust/rot and light weight) 48.3mm (4.4mm) scaffold tubes to construct the entire framework with either KeeKlamp-style fittings (like the path railings and cycle blockers in public footpaths) or some other scaffold support clamps. Then using double-sided fixing brackets (look a bit like the Greek letter omega) to fix the wooden 'rafters' to.

Vertical 'posts' ~2 meters spanning (away from property wall), and 1.85 meters apart (fence panel + 1 inch for concrete post).

Concrete footings (~30 cm x ~30 cm x ~60 cm deep) poured and levelled, with 'railing' baseplates (2 hex screws, 2 bolt down holes) being used to support the upright 'posts'. The baseplates seem like they are advised for climbing frames as well as railings, so I'd expect them to be pretty strong.

Double-sided fixing brackets attached to the (4) tubes that run lengthways atop the angled pieces.

A very dirty representation courtesy of my limited time in FreeCAD.

Am I utterly mad? Is this a workable project?

I'd prefer not to use wood as it needs treating and more long-term care.

Aluminium seems preferable, but is it strong enough? I haven't worked with the stuff, but how much does a 2 meter 48mm Al tube bend?

Whilst a 20 ft /6 meter Al tube is only 10 kg, I think it's rather unwieldy. I could do 6 m and 5 m lengths, joined and cut to absolute size, but I am considering working with 3 meter length exclusively and offsetting with adding additional bracings and/or 'joiner' couplings.

Thanks for suggestions, comments and any feedback.