- Joined

- 29 Mar 2023

- Messages

- 12

- Reaction score

- 0

- Country

Hi,

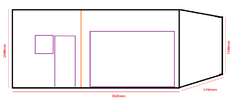

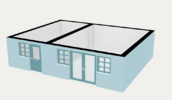

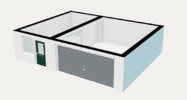

We are converting a double detached garage at the back of our garden. It will need building regs approval because of the size (45sqm) and being at the boundary on 3 sides.

I am struggling with the roof - The open span of it (5.79m) is not even in the span tables so I am imagining we will need to get a steel installed. A builder said they'd use 7x2 timbers but that wouldn't satisfy building regs. Would we be better off getting a structural engineer to design it? Has anyone had this done and estimate a cost?

Alternatively, I have been looking at posi joists but they would be £400 each for the span we need.

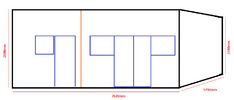

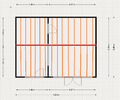

Would one posi joist the whole width of the building with joists running to it work? (Shown in image 1).

Some drawings/photos for details. (can you tell I got bored of drawing straight orange lines? Only for reference, not to scale)

ETA: The orange line on the front of the sketch is an internal single brick wall with a rotten, wooden framed window in it. The window will be filled in but i'm not sure if that wall is at all helpful in the construction of the roof (weight bearing etc).

We are converting a double detached garage at the back of our garden. It will need building regs approval because of the size (45sqm) and being at the boundary on 3 sides.

I am struggling with the roof - The open span of it (5.79m) is not even in the span tables so I am imagining we will need to get a steel installed. A builder said they'd use 7x2 timbers but that wouldn't satisfy building regs. Would we be better off getting a structural engineer to design it? Has anyone had this done and estimate a cost?

Alternatively, I have been looking at posi joists but they would be £400 each for the span we need.

Would one posi joist the whole width of the building with joists running to it work? (Shown in image 1).

Some drawings/photos for details. (can you tell I got bored of drawing straight orange lines? Only for reference, not to scale)

ETA: The orange line on the front of the sketch is an internal single brick wall with a rotten, wooden framed window in it. The window will be filled in but i'm not sure if that wall is at all helpful in the construction of the roof (weight bearing etc).

Attachments

-

Garage Before Sketch.png9.9 KB · Views: 45

Garage Before Sketch.png9.9 KB · Views: 45 -

Garage Floorplan.png55.5 KB · Views: 50

Garage Floorplan.png55.5 KB · Views: 50 -

Garage 3D Plan.png89.6 KB · Views: 49

Garage 3D Plan.png89.6 KB · Views: 49 -

Garage 3D.png98.3 KB · Views: 52

Garage 3D.png98.3 KB · Views: 52 -

IMG_20230914_101612.jpg490 KB · Views: 51

IMG_20230914_101612.jpg490 KB · Views: 51 -

IMG_20230914_101627.jpg270.3 KB · Views: 53

IMG_20230914_101627.jpg270.3 KB · Views: 53 -

Garage After Sketch.png5.3 KB · Views: 51

Garage After Sketch.png5.3 KB · Views: 51 -

Image 1 - Garage Roof Construction.png45.5 KB · Views: 47

Image 1 - Garage Roof Construction.png45.5 KB · Views: 47

Last edited: