Hello, I'm a newbie to the forum and a relative novice to DIY, especially garden related projects, i am looking to construct a timber decking area in my garden 3.0m x 3.0m to support a hydrotherapy pool for my dog, I want the deck board finish height to be flush with my lawn.

So far I have dug out the area and down 15 inches, compacted the soil/clay ground till that was level, tipped in old broken up stone roofing slates mixed with other quarry stone crush, compacted that level, compacted 1.5 tonnes of quarry sand over the stone crush till absolutely solid and level.

All the time not really knowing what I was doing, had it not been for Google and YouTube, I still don't really know if what I've done so far is correct, after watching many YouTube clips on laying block paving, I thought this was my next step, I must also say, as I hear some of you shout, why not pour a concrete base, I do not like concrete anywhere in my garden.

I was lucky enough to be donated as many as I needed 18" X 18" x 3" paving slabs, so this is what I laid onto a bed of sand, on top of the already mentioned foundation base, after much adjusting with a pavers rubber Mallet, I then used the whacker plate to compact this, to settle or unsettle any suspect paving slabs.

Just 3 needed to be lifted and reset, I now have a 3.0m x 3.0m absolutely dead level paved area, that does not move in any direction, as it is locked in around the outer edge with a locking stone perimeter, this paved area has been laid for 6 weeks now, and endured lots of rain, at one point we had rain constantly for 14 hours, this is when I discovered a slight issue, non of the pavers moved, that said, the hole in which they lay is now 8 inches below my lawn, and after 14 hours of rain, the pavers ended up being submerged under 10mm of water, which did drain away slowly over 2 hours.

I did not give any thought to drainage nor did it even cross my mind, and I don't want to undo any of my hard work, so I still intend to press on with the timber construction, it is at this stage I got so many conflicting advice on what I should do, so what I have done is use Google again, and ordered the following, which has now arrived apart from the fasteners.

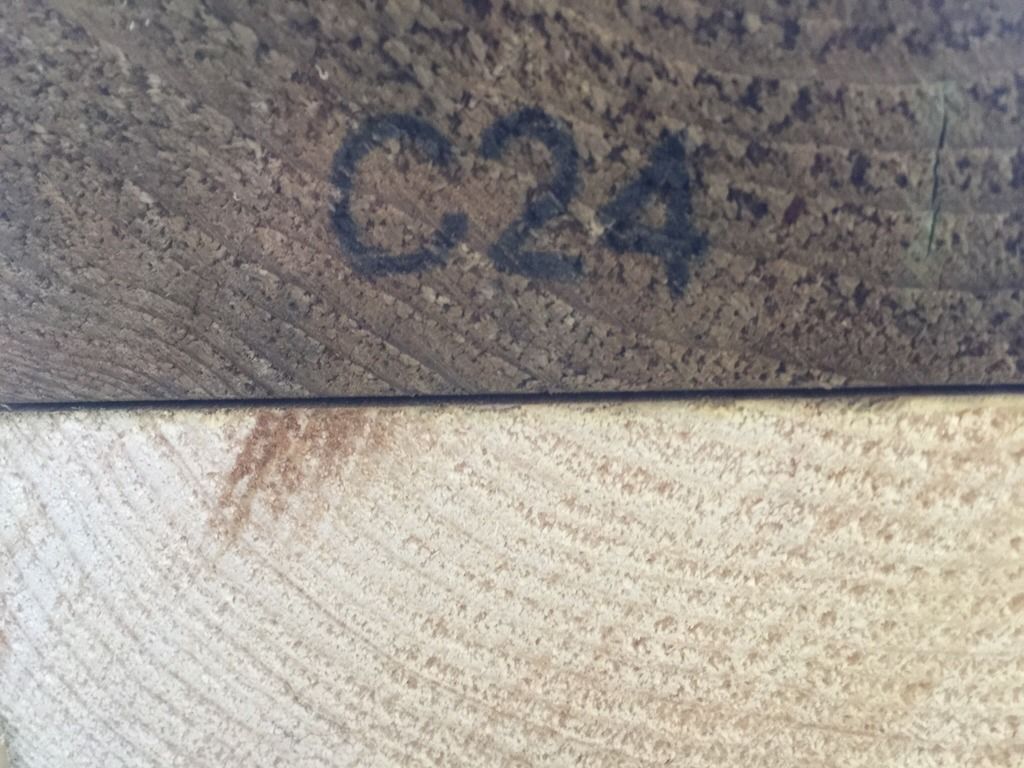

C24 6 x 2 treated with class 4 ground contact which came in 4.8m lengths, this will form the substructure frame, simply placed directly onto the paved area, this substructure frame will then be topped off with C24 5 x 2 again treated with class 4 ground contact treatment, all fixing screws are A4 stainless steel by Spax.

Hopefully this will be enough to support my dogs hydrotherapy pool with a wet weight of 5 tonnes, can anyone see any further pitfalls or mistakes before I build the timber frame ?

Many thanks.

So far I have dug out the area and down 15 inches, compacted the soil/clay ground till that was level, tipped in old broken up stone roofing slates mixed with other quarry stone crush, compacted that level, compacted 1.5 tonnes of quarry sand over the stone crush till absolutely solid and level.

All the time not really knowing what I was doing, had it not been for Google and YouTube, I still don't really know if what I've done so far is correct, after watching many YouTube clips on laying block paving, I thought this was my next step, I must also say, as I hear some of you shout, why not pour a concrete base, I do not like concrete anywhere in my garden.

I was lucky enough to be donated as many as I needed 18" X 18" x 3" paving slabs, so this is what I laid onto a bed of sand, on top of the already mentioned foundation base, after much adjusting with a pavers rubber Mallet, I then used the whacker plate to compact this, to settle or unsettle any suspect paving slabs.

Just 3 needed to be lifted and reset, I now have a 3.0m x 3.0m absolutely dead level paved area, that does not move in any direction, as it is locked in around the outer edge with a locking stone perimeter, this paved area has been laid for 6 weeks now, and endured lots of rain, at one point we had rain constantly for 14 hours, this is when I discovered a slight issue, non of the pavers moved, that said, the hole in which they lay is now 8 inches below my lawn, and after 14 hours of rain, the pavers ended up being submerged under 10mm of water, which did drain away slowly over 2 hours.

I did not give any thought to drainage nor did it even cross my mind, and I don't want to undo any of my hard work, so I still intend to press on with the timber construction, it is at this stage I got so many conflicting advice on what I should do, so what I have done is use Google again, and ordered the following, which has now arrived apart from the fasteners.

C24 6 x 2 treated with class 4 ground contact which came in 4.8m lengths, this will form the substructure frame, simply placed directly onto the paved area, this substructure frame will then be topped off with C24 5 x 2 again treated with class 4 ground contact treatment, all fixing screws are A4 stainless steel by Spax.

Hopefully this will be enough to support my dogs hydrotherapy pool with a wet weight of 5 tonnes, can anyone see any further pitfalls or mistakes before I build the timber frame ?

Many thanks.