Hi all

I have a heatbank in our selfbuild, that is hooked up to a Vaillant boiler and has been working fine in the 3 or so years since it's been fitted.

It's all situated on the ground floor, with a feed and expansion tank up in the loft. Boiler is controlled by twin thermostats fitted low down in the heatbank. Boiler pump runs at the lowest of the 3 speeds, and the thermostatic valve in the boiler return is set as low as it can go. Return temps to the boiler start at approx 40deg when the stats fire the boiler, rising to around 50deg when they shut off again. Temp rise across the boiler is approx 25deg.

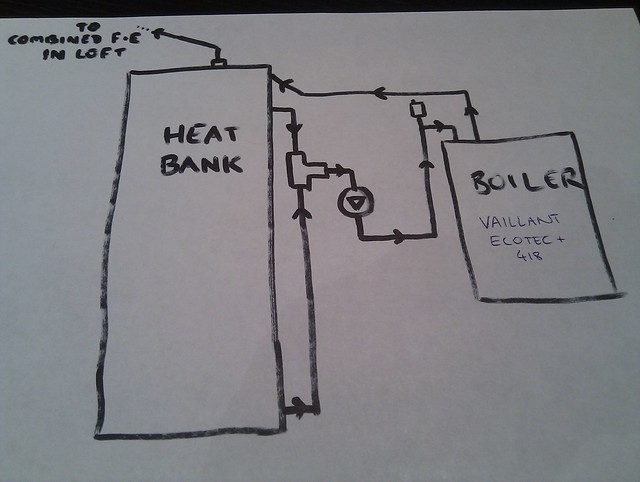

Here's a quick sketch of how it's currently setup:

(I've omitted the UFH & other connection gubbins for now)

Note that the pipe to the F&E in loft is also the vent (all 22mm pipe).

I've been intending to relocate the F&E tank, for various reasons, so it's directly above the heatbank rather than up in the loft.

I started reading the boiler manual to work out how best to connect the F&E tank, and vent.

I noticed in the boiler manual, and in most other diagrams online, that it seems more common for the pump to be situated in the flow from the boiler, downstream of the feed & vent pipes.

But on ours, the pump is in the boiler return. The thermostatic valve and pump were pre-fitted on the heatbank by DPS, our plumber just hooked it up to the boiler.

We've not had any problems running it though.

So my questions:

(1) Is it OK for the feed & vent to be taken from the top of the heatbank as per my diagram ?

(2) If not, and I were to relocate the feed & vent, where should it connect in to the boiler flow/return pipework in the above diagram ? And is it better to combine the F&V ?

(3) Could I run the vent straight out of the wall so it vents outside in case of a fault ?

(4) Is there any point in having the thermostatic valve in the boiler return ? It's set as low as it can go, I can't see any benefit compared to just running the boiler return directly from the bottom of the heatbank. Only time I can see it doing anything useful is during (very rare) startups from cold, so the boiler output is always at full temp (giving instant heat to the top of the heatbank and therefore hot tap water heat exchanger) even when the bottom of the heatbank is stone cold. In my mind the thermostatic valve is just a mass of brass radiating precious heat away!

Thanks for any thoughts or other observations !

I have a heatbank in our selfbuild, that is hooked up to a Vaillant boiler and has been working fine in the 3 or so years since it's been fitted.

It's all situated on the ground floor, with a feed and expansion tank up in the loft. Boiler is controlled by twin thermostats fitted low down in the heatbank. Boiler pump runs at the lowest of the 3 speeds, and the thermostatic valve in the boiler return is set as low as it can go. Return temps to the boiler start at approx 40deg when the stats fire the boiler, rising to around 50deg when they shut off again. Temp rise across the boiler is approx 25deg.

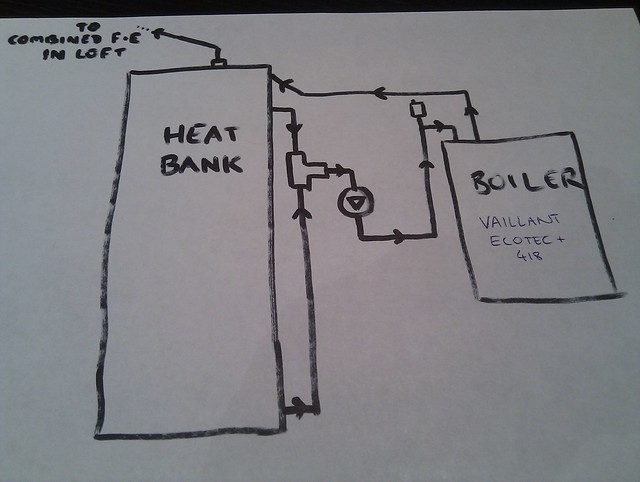

Here's a quick sketch of how it's currently setup:

(I've omitted the UFH & other connection gubbins for now)

Note that the pipe to the F&E in loft is also the vent (all 22mm pipe).

I've been intending to relocate the F&E tank, for various reasons, so it's directly above the heatbank rather than up in the loft.

I started reading the boiler manual to work out how best to connect the F&E tank, and vent.

I noticed in the boiler manual, and in most other diagrams online, that it seems more common for the pump to be situated in the flow from the boiler, downstream of the feed & vent pipes.

But on ours, the pump is in the boiler return. The thermostatic valve and pump were pre-fitted on the heatbank by DPS, our plumber just hooked it up to the boiler.

We've not had any problems running it though.

So my questions:

(1) Is it OK for the feed & vent to be taken from the top of the heatbank as per my diagram ?

(2) If not, and I were to relocate the feed & vent, where should it connect in to the boiler flow/return pipework in the above diagram ? And is it better to combine the F&V ?

(3) Could I run the vent straight out of the wall so it vents outside in case of a fault ?

(4) Is there any point in having the thermostatic valve in the boiler return ? It's set as low as it can go, I can't see any benefit compared to just running the boiler return directly from the bottom of the heatbank. Only time I can see it doing anything useful is during (very rare) startups from cold, so the boiler output is always at full temp (giving instant heat to the top of the heatbank and therefore hot tap water heat exchanger) even when the bottom of the heatbank is stone cold. In my mind the thermostatic valve is just a mass of brass radiating precious heat away!

Thanks for any thoughts or other observations !