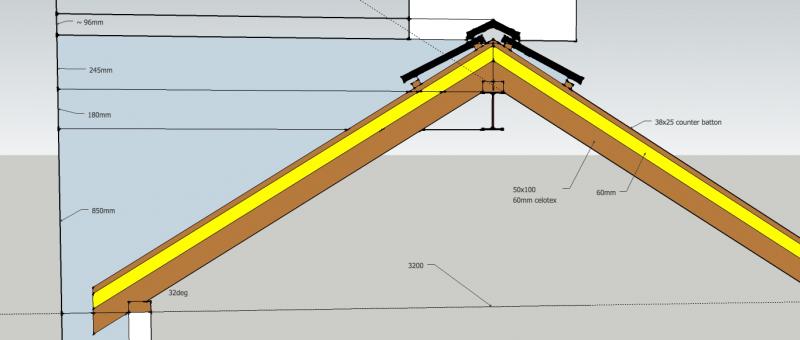

Made a mistake with placing rsj 178x100 slightly too high (one end is built into an external wall, the top of the rsj being 230mm below a second storey window cill)

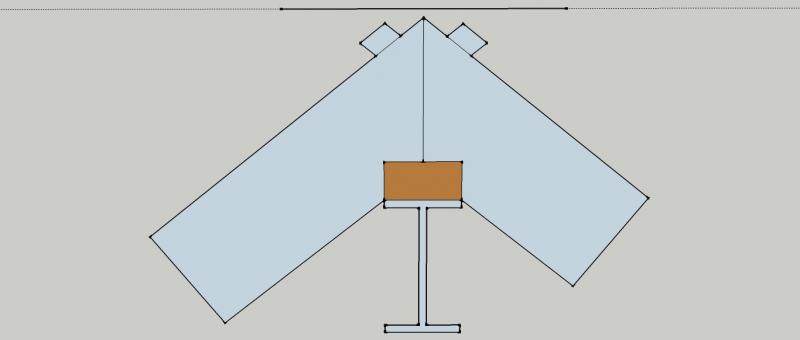

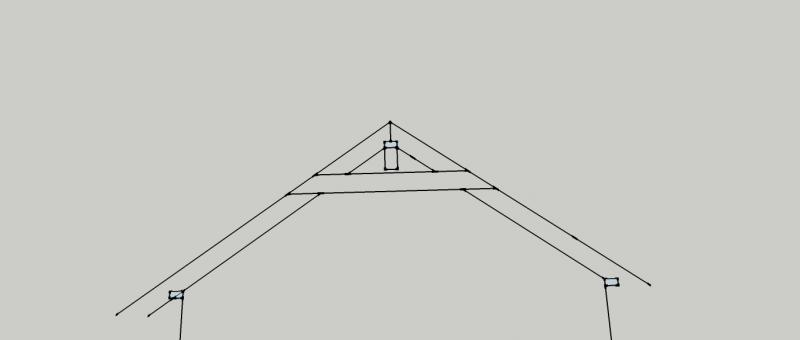

this is for an single story roof (span 3.2m, 38deg pitch beam centre 1.6m)

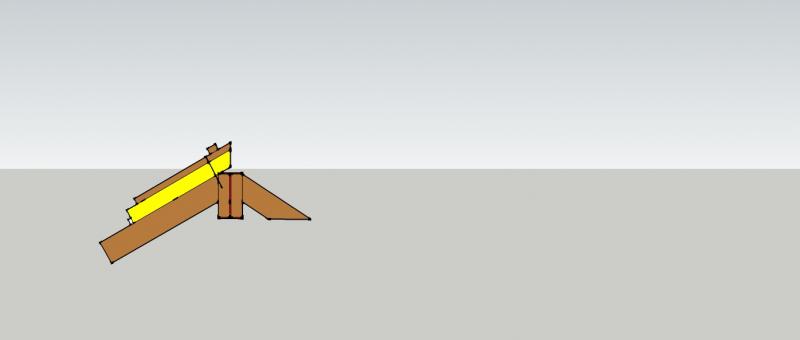

rafter spec was 150x50@450 centres with 100mm insulation between, but with tiles takes the mid point too high

is there any way i can still create a warm roof with having to lower my beam to get the ridge tile low enough ???

this is for an single story roof (span 3.2m, 38deg pitch beam centre 1.6m)

rafter spec was 150x50@450 centres with 100mm insulation between, but with tiles takes the mid point too high

is there any way i can still create a warm roof with having to lower my beam to get the ridge tile low enough ???