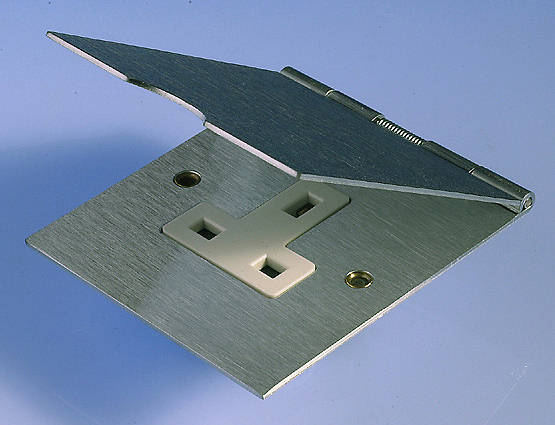

Going to fit some floor sockets (the metal ones with the metal flaps) soon, and just realised I have probably only fitted a few, many years ago, hence a question:

Once the flushed in box is installed and all the screedwork is done, should the socket be fitted next, or the floor covering (laminated wood or carpet at a guess)?

The main reason for my enquiry is because if the floor covering is done first this means the socket would be more of a trip hazard, perhaps.

What's the normal procedure here?

Once the flushed in box is installed and all the screedwork is done, should the socket be fitted next, or the floor covering (laminated wood or carpet at a guess)?

The main reason for my enquiry is because if the floor covering is done first this means the socket would be more of a trip hazard, perhaps.

What's the normal procedure here?