hi,

i am very new to this, and i would appreciate your insights.

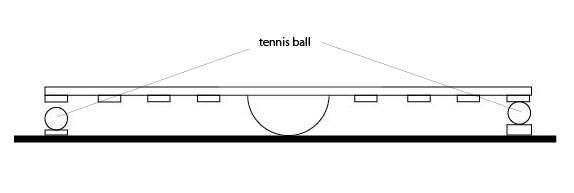

i am planning a temporary art installation of wobbly floor which will last about 3 weeks.

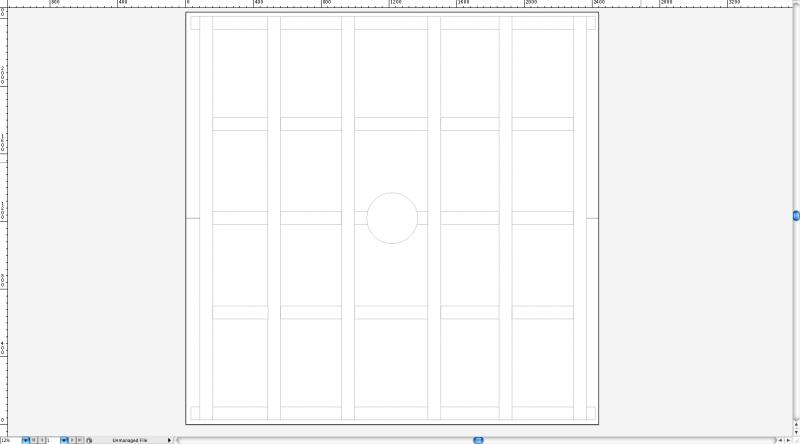

the floor has to be 2.44 m x 2.44 m and around it, temporary walls and a door.

i want the whole floor to wobble as one sheet.

there will be more than 2 person on the floor at any given time.

this goes on top of a solid cement floor.

what material and method would be the best and cost effective for this project?

doesn't mdf tend to bend a lot?

i want it to not bend or sag so much because this will kill the wobble...

please help me!

i am very new to this, and i would appreciate your insights.

i am planning a temporary art installation of wobbly floor which will last about 3 weeks.

the floor has to be 2.44 m x 2.44 m and around it, temporary walls and a door.

i want the whole floor to wobble as one sheet.

there will be more than 2 person on the floor at any given time.

this goes on top of a solid cement floor.

what material and method would be the best and cost effective for this project?

doesn't mdf tend to bend a lot?

i want it to not bend or sag so much because this will kill the wobble...

please help me!