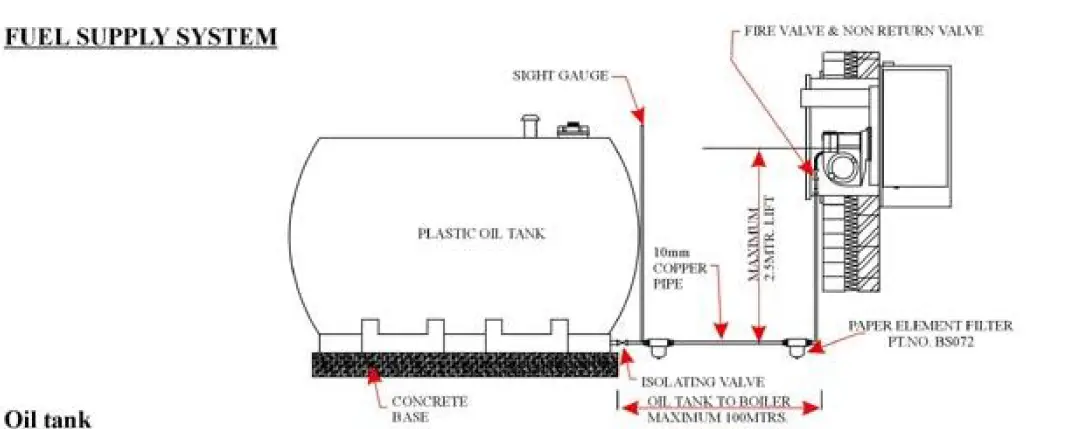

Here's your spec, if the "fire valve & non return valve" are one, which they appear to be, then presume it is installed vertically as shown?, if the NRV isnt 100% tight then would imagine that the oil in the pipe below it could empty out down to the level in the oil tank and even though the pump can lift 2.5M then it would have to fill or at least partly fill this line again, by which time the burner may have tripped out even though it does a ~ 12 sec purge and then allows 5sec to flame detection. Maybe a very lightly loaded spring typoe NRV installed at the tank outlet may help?. If the boiler runs OK during the day but is inclined to trip in the morning after say 8hrs off then more time for the oil to drain back.

Re: the Tiger Loop, they merely say its not required but I would certainly look at installing one if my tank was well below the pump as the tiger loop is a deaerator.

Re: the Tiger Loop, they merely say its not required but I would certainly look at installing one if my tank was well below the pump as the tiger loop is a deaerator.

Last edited: