You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is this a load bearing wall?

- Thread starter Last Triumph

- Start date

Now *there's* a thought...Dont forget to let him have your paypal details Shy

Any one can give beam sizes (even me  ) but its the unreadable scrawl and figures that make the ££££s and are required by Mr Surveyor

) but its the unreadable scrawl and figures that make the ££££s and are required by Mr Surveyor

Don't say I don't do anything for you

Span length & partial factors for loading

Span Factors for moments & forces Factors for deflection

(mm) gfd gfi gfw gdd gdi gdw

3100 1.40 1.60 0.00 1.00 1.00 1.00

Load descriptions

Loads are applied normal to the major principal axis (x-axis) of the member.

Ref. Category Description

1 "Dead" "beam sw"

2 "Dead" "floor dead"

3 "Imposed" "floor live"

4 "Dead" "partition"

Loading data (unfactored)

Ref. Category Type Load Position Load Position

kN/m mm kN/m mm

1 "Dead" UDL 0.2 0 - 3100

2 "Dead" UDL 1.3 0 - 3100

3 "Imposed" UDL 3.8 0 - 3100

4 "Dead" UDL 1.1 0 - 3100

Analysis results - entire span

Ra Rb Fvy Mx Deflection: dEIx

kN (fac) kN (fac) kN (fac) kNm (fac) Sense kNm3 Direction

14.8 14.8 14.8 11.4 "Sagging"7.54 "Down"Unfactored support reactions

Support A; Dead load; -3.9 kN; Live load; -5.8 kN; Wind load; 0.0 kN;

Support B; Dead load; -3.9 kN; Live load; -5.8 kN; Wind load; 0.0 kN;

LTB segment results

Seg. xs xe LLT MLT MmLT2 MmLT3 MmLT4

mm mm mm kNm (fac) kNm (fac) kNm (fac) kNm (fac)

1 0 3100 3100 11.4 8.6 11.4 8.6

Member design checks for a simply-supported single-span beam to BS 5950 (with LTB)

Summary of results;

Material; Grade = "S275"; py = 275 N/mm2;

Section; "UB 152x89x16"; Classification; "Plastic";

Check; Load; Capacity; Notes; Result;

Deflection; dy_max = 4.4 mm; dlim = 8.6 mm; Span / 360 or 12.0 mm; Pass

Shear; Fvy = 14.8 kN; Pvy = 113.2 kN; Low shear; Pass;

Moment; Mx = 11.4 kNm; Mcx = 33.9 kNm; Low shear; Pass

LTB; MLT = 11.4 kNm; Mb / mLT

= 14.6 kNm; LE_LT = 4.0 m;

mLT = 0.93; Pass;

and:

Masonry details

Masonry type; Autoclaved aerated concrete blocks

Compressive strength of unit; punit = 3.6 N/mm2

Mortar designation; iii

Least horizontal dimension of masonry units; lunit = 100 mm

Height of masonry units; hunit = 215 mm

Category of masonry units; Category II

Category of construction control ; Normal

Partial safety factor for material strength; gm = 3.5

Thickness of load bearing leaf; t = 100 mm

Effective thickness of masonry wall; tef = 100 mm

Height of masonry wall; h = 2400 mm

Effective height of masonry wall; hef = 2400 mm

Bearing details

Beam spanning in plane of wall

Width of bearing; B = 100 mm

Length of bearing; lb = 150 mm

Compressive strength from Table 2 BS5628 art 1 - autoclaved aerated concrete blocks

art 1 - autoclaved aerated concrete blocks

Mortar designation; Mortar = "iii"

Block compressive strength; punit = 3.6 N/mm2

Characteristic compressive strength (Table 2b); fkb = 1.70 N/mm2

Characteristic compressive strength (Table 2e); fke = 3.50 N/mm2

Height of solid block; hunit = 215.0 mm ;

Least horizontal dimension; lunit = 100.0 mm

Block ratio; ratio = hunit / lunit = 2.2

Ratio between 0.6 and 4.5 - OK

Characteristic compressive strength; fk = 3.50 N/mm2

Loading details

Characteristic dead load; Gk = 4 kN

Characteristic imposed load; Qk = 6 kN

Design load on bearing; F = (Gk ´ 1.4) + (Qk ´ 1.6) = 14.7 kN

Masonry bearing type

Bearing type; Type 2

Bearing safety factor; gbear = 1.50

Check design bearing without a spreader

Design bearing stress; fca = F / (B ´ lb) = 0.983 N/mm2

Allowable bearing stress; fcp = gbear ´ fk / gm = 1.500 N/mm2

PASS - Allowable bearing stress exceeds design bearing stress

Check design bearing at 0.4 ´ h below the bearing level

Slenderness ratio; hef / tef = 24.00

Eccentricity at top of wall; ex = 0.0 mm

From BS5268:1 Table 7

Capacity reduction factor; b = 0.61

Length of bearing distributed at 0.4 ´ h; ld = 1110 mm

Maximum bearing stress; fca = F / (ld ´ t) = 0.133 N/mm2

Allowable bearing stress; fcp = b ´ fk / gm = 0.605 N/mm2

PASS - Allowable bearing stress at 0.4 ´ h below bearing level exceeds design bearing stress

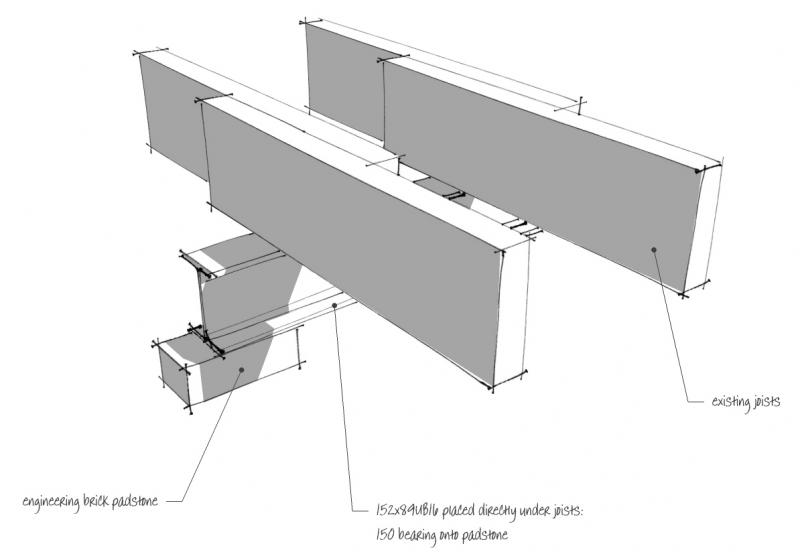

So that's a 152x89UB16 tight under the joists, with 150 bearing to an engineering brick each end.

Looks like this:

Span length & partial factors for loading

Span Factors for moments & forces Factors for deflection

(mm) gfd gfi gfw gdd gdi gdw

3100 1.40 1.60 0.00 1.00 1.00 1.00

Load descriptions

Loads are applied normal to the major principal axis (x-axis) of the member.

Ref. Category Description

1 "Dead" "beam sw"

2 "Dead" "floor dead"

3 "Imposed" "floor live"

4 "Dead" "partition"

Loading data (unfactored)

Ref. Category Type Load Position Load Position

kN/m mm kN/m mm

1 "Dead" UDL 0.2 0 - 3100

2 "Dead" UDL 1.3 0 - 3100

3 "Imposed" UDL 3.8 0 - 3100

4 "Dead" UDL 1.1 0 - 3100

Analysis results - entire span

Ra Rb Fvy Mx Deflection: dEIx

kN (fac) kN (fac) kN (fac) kNm (fac) Sense kNm3 Direction

14.8 14.8 14.8 11.4 "Sagging"7.54 "Down"Unfactored support reactions

Support A; Dead load; -3.9 kN; Live load; -5.8 kN; Wind load; 0.0 kN;

Support B; Dead load; -3.9 kN; Live load; -5.8 kN; Wind load; 0.0 kN;

LTB segment results

Seg. xs xe LLT MLT MmLT2 MmLT3 MmLT4

mm mm mm kNm (fac) kNm (fac) kNm (fac) kNm (fac)

1 0 3100 3100 11.4 8.6 11.4 8.6

Member design checks for a simply-supported single-span beam to BS 5950 (with LTB)

Summary of results;

Material; Grade = "S275"; py = 275 N/mm2;

Section; "UB 152x89x16"; Classification; "Plastic";

Check; Load; Capacity; Notes; Result;

Deflection; dy_max = 4.4 mm; dlim = 8.6 mm; Span / 360 or 12.0 mm; Pass

Shear; Fvy = 14.8 kN; Pvy = 113.2 kN; Low shear; Pass;

Moment; Mx = 11.4 kNm; Mcx = 33.9 kNm; Low shear; Pass

LTB; MLT = 11.4 kNm; Mb / mLT

= 14.6 kNm; LE_LT = 4.0 m;

mLT = 0.93; Pass;

and:

Masonry details

Masonry type; Autoclaved aerated concrete blocks

Compressive strength of unit; punit = 3.6 N/mm2

Mortar designation; iii

Least horizontal dimension of masonry units; lunit = 100 mm

Height of masonry units; hunit = 215 mm

Category of masonry units; Category II

Category of construction control ; Normal

Partial safety factor for material strength; gm = 3.5

Thickness of load bearing leaf; t = 100 mm

Effective thickness of masonry wall; tef = 100 mm

Height of masonry wall; h = 2400 mm

Effective height of masonry wall; hef = 2400 mm

Bearing details

Beam spanning in plane of wall

Width of bearing; B = 100 mm

Length of bearing; lb = 150 mm

Compressive strength from Table 2 BS5628

Mortar designation; Mortar = "iii"

Block compressive strength; punit = 3.6 N/mm2

Characteristic compressive strength (Table 2b); fkb = 1.70 N/mm2

Characteristic compressive strength (Table 2e); fke = 3.50 N/mm2

Height of solid block; hunit = 215.0 mm ;

Least horizontal dimension; lunit = 100.0 mm

Block ratio; ratio = hunit / lunit = 2.2

Ratio between 0.6 and 4.5 - OK

Characteristic compressive strength; fk = 3.50 N/mm2

Loading details

Characteristic dead load; Gk = 4 kN

Characteristic imposed load; Qk = 6 kN

Design load on bearing; F = (Gk ´ 1.4) + (Qk ´ 1.6) = 14.7 kN

Masonry bearing type

Bearing type; Type 2

Bearing safety factor; gbear = 1.50

Check design bearing without a spreader

Design bearing stress; fca = F / (B ´ lb) = 0.983 N/mm2

Allowable bearing stress; fcp = gbear ´ fk / gm = 1.500 N/mm2

PASS - Allowable bearing stress exceeds design bearing stress

Check design bearing at 0.4 ´ h below the bearing level

Slenderness ratio; hef / tef = 24.00

Eccentricity at top of wall; ex = 0.0 mm

From BS5268:1 Table 7

Capacity reduction factor; b = 0.61

Length of bearing distributed at 0.4 ´ h; ld = 1110 mm

Maximum bearing stress; fca = F / (ld ´ t) = 0.133 N/mm2

Allowable bearing stress; fcp = b ´ fk / gm = 0.605 N/mm2

PASS - Allowable bearing stress at 0.4 ´ h below bearing level exceeds design bearing stress

So that's a 152x89UB16 tight under the joists, with 150 bearing to an engineering brick each end.

Looks like this:

- Joined

- 13 Jul 2007

- Messages

- 118

- Reaction score

- 0

- Country

WOW - what can I say other than thank you VERY much!

Given my dimensions are only aproximate and may be off be a few inches, will that ultimately alter the size of the beam I need?

Will I be able to buy and install that beam and just get a council surveyor to inspect it before it's closed up, or will I need to show him that list of calcs.

Sorry if I sound dumb, but I've never done this sort of thing before and don't want a nast shock if I sell the house and don't have the correct paperwork.

Given my dimensions are only aproximate and may be off be a few inches, will that ultimately alter the size of the beam I need?

Will I be able to buy and install that beam and just get a council surveyor to inspect it before it's closed up, or will I need to show him that list of calcs.

Sorry if I sound dumb, but I've never done this sort of thing before and don't want a nast shock if I sell the house and don't have the correct paperwork.

No, the beam is adequate, unless you're planning on adding another half metre or so to the span!

You will need to get a BCO to check the installation and give you a ticket on completion. Just print out the calcs and detail and that should shut him up. Unless it's bcsurveyor and who knows what might happen...

You need to fire protect the beam. 12 plasterboard and skim will suffice.

You will need to get a BCO to check the installation and give you a ticket on completion. Just print out the calcs and detail and that should shut him up. Unless it's bcsurveyor and who knows what might happen...

You need to fire protect the beam. 12 plasterboard and skim will suffice.

- Joined

- 13 Jul 2007

- Messages

- 118

- Reaction score

- 0

- Country

Genuinely, thanks very much!

- Joined

- 13 Jul 2007

- Messages

- 118

- Reaction score

- 0

- Country

Some progress and questions....

I spoke to the inspector at Wirral Borough Council today who was very helpful indeed. He said that as long as the beam is obviously 'up to the job' calcs wouldn't be needed. Inspection is £98.

Someone suggested a Catnic box lintel CN6XB to do the job and at first this sounded great as the calcs are in the public domain and they are ready to plaster etc.

However, I'm not sure if I can rest the floor joists directly onto a Catnic box lintel or whether it will need a course of engineering block above it first which would render the lintel too low to look good.

I'm trying to weigh up the cost / versus dificulty / suitability and could do with some guidence please.

Is ther a difference in how a UB should be mounted against a catnic?

Catnic say just 1 course of engineering block will suffice, but is a UB different - I hear people mention pad stones and wedges etc? What and why are there differences in how they bear / mount.

Sorry for all the questions - I'm learning all the time.

Oh, and the perpendicular walls that will have the beam bear onto it are only 100mm wide (same as wall being removed), not the ideal 150mm suggested....

I spoke to the inspector at Wirral Borough Council today who was very helpful indeed. He said that as long as the beam is obviously 'up to the job' calcs wouldn't be needed. Inspection is £98.

Someone suggested a Catnic box lintel CN6XB to do the job and at first this sounded great as the calcs are in the public domain and they are ready to plaster etc.

However, I'm not sure if I can rest the floor joists directly onto a Catnic box lintel or whether it will need a course of engineering block above it first which would render the lintel too low to look good.

I'm trying to weigh up the cost / versus dificulty / suitability and could do with some guidence please.

Is ther a difference in how a UB should be mounted against a catnic?

Catnic say just 1 course of engineering block will suffice, but is a UB different - I hear people mention pad stones and wedges etc? What and why are there differences in how they bear / mount.

Sorry for all the questions - I'm learning all the time.

Oh, and the perpendicular walls that will have the beam bear onto it are only 100mm wide (same as wall being removed), not the ideal 150mm suggested....

Catnic figures in brackets:

You've got a total load of 19.84kN (39)

Ixx required 436cm^4 dead and live 259cm^4 live only (904)

Zxx required 42.71cm^3 (78)

Moment 7.69kNm (12.7)

So, CN6XB is fine, but is 144mm deeper than the beam alternative; a CN5XC would also work, but doesn't come in a long enough stock length, which is a shame, as this is 143mm deep.

You don't need a row of engineer bricks on top and a bearing of 100mm is ok in this situation. No difference in how you install v the beam alternative wrt bearings, packing up etc.

HTH

You've got a total load of 19.84kN (39)

Ixx required 436cm^4 dead and live 259cm^4 live only (904)

Zxx required 42.71cm^3 (78)

Moment 7.69kNm (12.7)

So, CN6XB is fine, but is 144mm deeper than the beam alternative; a CN5XC would also work, but doesn't come in a long enough stock length, which is a shame, as this is 143mm deep.

You don't need a row of engineer bricks on top and a bearing of 100mm is ok in this situation. No difference in how you install v the beam alternative wrt bearings, packing up etc.

HTH

- Joined

- 13 Jul 2007

- Messages

- 118

- Reaction score

- 0

- Country

Spoke to Catnic today who said that under no circumstances should I install one of their box lintels directly under the joists. I need apparently 225mm minimum blockwork between the lintel and joist.

I priced them up at best part of £300 inc delivery and decided to stick to a universal beam so remove any doubt.

Spoke to a few steel stockists who were unable to offer the beam size you mentioned and all offered a 178x102x19kg instead.

I guess this is just a heavier duty version of your reccommendation?

I have no issue in going bigger for obvious reasons.

I can get one delivered next day, cut to length for £102 which I thought was more than reasonable and cemented my decision for a beam.

When you kindly ran those calcs for me lat time, I don't think I'd given you all the facts to work from, so just before I order the beam, here is some data that should clarify the requirements...

Within the two perpendicular walls there are 10 joists in total, most single with two sets of doubles.

Joists are all in one piece for the full length and do not overlap

Total joist span accross both rooms = 4800mm

Joist size = 190mm x 45mm

Width of room(s) / wall to be removed / beam = 3,050mm + bearings

Wall to be removed is 150mm away from being dead centre between the rooms.

Above is a bedroom and bathroom divided by a hollow stud wall that is free standing and not linked into any part of the roof.

Many thanks.

I priced them up at best part of £300 inc delivery and decided to stick to a universal beam so remove any doubt.

Spoke to a few steel stockists who were unable to offer the beam size you mentioned and all offered a 178x102x19kg instead.

I guess this is just a heavier duty version of your reccommendation?

I have no issue in going bigger for obvious reasons.

I can get one delivered next day, cut to length for £102 which I thought was more than reasonable and cemented my decision for a beam.

When you kindly ran those calcs for me lat time, I don't think I'd given you all the facts to work from, so just before I order the beam, here is some data that should clarify the requirements...

Within the two perpendicular walls there are 10 joists in total, most single with two sets of doubles.

Joists are all in one piece for the full length and do not overlap

Total joist span accross both rooms = 4800mm

Joist size = 190mm x 45mm

Width of room(s) / wall to be removed / beam = 3,050mm + bearings

Wall to be removed is 150mm away from being dead centre between the rooms.

Above is a bedroom and bathroom divided by a hollow stud wall that is free standing and not linked into any part of the roof.

Many thanks.

Complete horlicks from them. Although - technically - it's a series of point loads, the loads are not heavy per joist and it's fine to take it as a UDL directly on the top: it does not rely on composite action with the brickwork to generate the load capacity. Anyhoo, like I said somewhere else, Crapnix will always be way more expensive than a simple ol' beam.

Are you saying joist span is 4.8m in total or both sides? If the former, my original design is well in and a 178x102 is stronger than a 152x89, so no problem; and if the latter, the 178 is fine anyway. I took the partition on top of the wall, in reality it's slightly less load onto the beam.

Are you saying joist span is 4.8m in total or both sides? If the former, my original design is well in and a 178x102 is stronger than a 152x89, so no problem; and if the latter, the 178 is fine anyway. I took the partition on top of the wall, in reality it's slightly less load onto the beam.

- Joined

- 13 Jul 2007

- Messages

- 118

- Reaction score

- 0

- Country

Thanks

4.8, total span with the beam in the middle....

I'll order the beam today.

Just a final two questions though - Is a single engineering block under each end suficient as a pad stone bearing? And what would you recommend as a 'wedge' to force it up hard to the joists?

Also, is it acceptable when using acros and a heavy plank to apply the plank directly on to the plaster board ceiling, or must the plaster board plank only rest on the joists, meaning I'll have to pull down a chunk of ceiling?

Thanks again.

4.8, total span with the beam in the middle....

I'll order the beam today.

Just a final two questions though - Is a single engineering block under each end suficient as a pad stone bearing? And what would you recommend as a 'wedge' to force it up hard to the joists?

Also, is it acceptable when using acros and a heavy plank to apply the plank directly on to the plaster board ceiling, or must the plaster board plank only rest on the joists, meaning I'll have to pull down a chunk of ceiling?

Thanks again.

Ahah another Sketchup afficionado  .

.

Yep eng brick is fine, but just turn it through 90° from my detail. Cut out a slot for the eng brick either end, put the beam in first and acrow it up to the underside of the joists so it's tight to them. Then install the padstone tight to the underside of the beam on a 10mm mortar bed. If you've got the cutting out depth wrong, don't put a thick mortar bed in, but pack between the padstone and the underside of the beam with slate or steel shims the following day, then remove the acrows.

Before you start knocking out, put the temp support on the side where the partition upstairs is, about 200 back from the wall face. You won't need supports both sides, as the joists can span to the temporary support in the short term, as they are continuous from one side of the building to the other. The deals can go directly onto the plasterboard ceiling.

Yep eng brick is fine, but just turn it through 90° from my detail. Cut out a slot for the eng brick either end, put the beam in first and acrow it up to the underside of the joists so it's tight to them. Then install the padstone tight to the underside of the beam on a 10mm mortar bed. If you've got the cutting out depth wrong, don't put a thick mortar bed in, but pack between the padstone and the underside of the beam with slate or steel shims the following day, then remove the acrows.

Before you start knocking out, put the temp support on the side where the partition upstairs is, about 200 back from the wall face. You won't need supports both sides, as the joists can span to the temporary support in the short term, as they are continuous from one side of the building to the other. The deals can go directly onto the plasterboard ceiling.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 1

- Views

- 138