I have now checked and replaced all the metal switches and sockets (other than the cooker switch which seems to be on very short trails and difficult to inspect or remove), but found something unexpected with one of the sockets.

As mentioned, one of the metal double sockets has three additional plastic doubles spurred off it - which I know is not allowed.

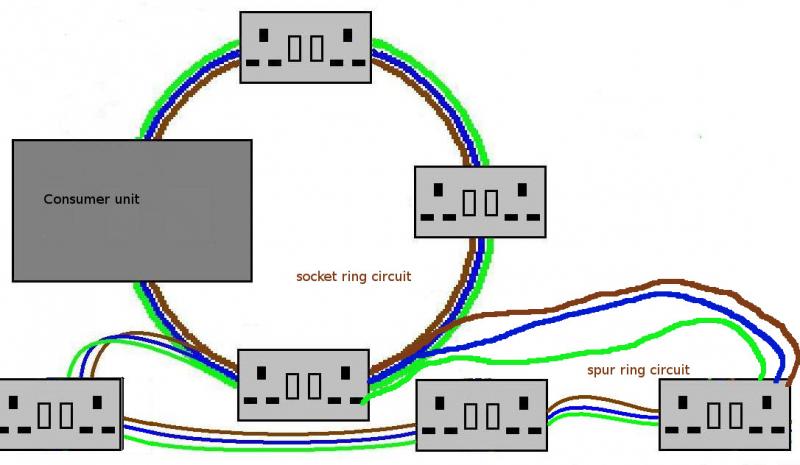

What surprised me slightly is the arrangement of the wiring. I was expecting to see each socket spurred off the previous one in a chain- which is sort of what's there. Additionally there is a cable from the last socket back to the original metal socket, forming a kind of secondary ring branched off from the socket ring circuit.

This means that the original metal socket has four sets of wires running into it, with the consequence that the installer was unable to securely connect them, the terminal screws being loose, and causing the wires to fall out when unscrewing the plate to inspect them.

I'm not sure I understand the idea behind this spurred ring- whether it's an attempt or way to get around the regulations on spurred sockets, whether it's safer, or less safe than if they were just spurred without the loop back cable, or what was intended.

Since I don't yet understand it, I've left the loop of sockets in place, (unused) and just replaced the metal socket and connected it properly. The loop wires, sockets and boxes etc are all modern, and it looks like it's been put in relatively recently, though the wiring is in a plastic conduit running above the skirting board.

I'm guessing the whole spur will have to be removed or at least two of the sockets and the extra cable, but just wasn't sure quite what to make of it.

As mentioned, one of the metal double sockets has three additional plastic doubles spurred off it - which I know is not allowed.

What surprised me slightly is the arrangement of the wiring. I was expecting to see each socket spurred off the previous one in a chain- which is sort of what's there. Additionally there is a cable from the last socket back to the original metal socket, forming a kind of secondary ring branched off from the socket ring circuit.

This means that the original metal socket has four sets of wires running into it, with the consequence that the installer was unable to securely connect them, the terminal screws being loose, and causing the wires to fall out when unscrewing the plate to inspect them.

I'm not sure I understand the idea behind this spurred ring- whether it's an attempt or way to get around the regulations on spurred sockets, whether it's safer, or less safe than if they were just spurred without the loop back cable, or what was intended.

Since I don't yet understand it, I've left the loop of sockets in place, (unused) and just replaced the metal socket and connected it properly. The loop wires, sockets and boxes etc are all modern, and it looks like it's been put in relatively recently, though the wiring is in a plastic conduit running above the skirting board.

I'm guessing the whole spur will have to be removed or at least two of the sockets and the extra cable, but just wasn't sure quite what to make of it.