Bod ignore those taking the pi ss I’m sure it will look great when it’s finished .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

D

Deleted member 294929

Dont come on ere stuttering your snobbery.Mmmm, brass munsen clip extenders ... nice

This ain't bloody Hertfordshire yer know.

This was all hand crafted from scratch with reclaimed materials.

Gord knows what you think of the coffee table.

D

Deleted member 294929

Bod ignore those taking the pi ss I’m sure it will look great when it’s finished .

Exactly. ....

I'm not sure as yet my next step. I may connect it to the central heating or run an antique shower rose off the end.

Yes dry your wet jackets at the same time.

- Joined

- 22 Aug 2006

- Messages

- 7,160

- Reaction score

- 1,219

- Country

Amazing what people will pay. Ever seen "money for nothing"? People pay silly amounts for arty crap.Do people pay that sort of money?

The arty farty geezer seems to have glued the joints.

You could use electronic solder (and maybe an electric clamp type solder-melter). You get very neat joints. Or paste but iirc that's very expensive.

You could have fun with microbore soft copper, using the plier-type bender rather than the lever one, cos it gets in better. Much cheaper than fittings!

You misunderstand - this is not taking the pee, this is fraternal appreciation - here's my curtain rail:Dont come on ere stuttering your snobbery.

This ain't bloody Hertfordshire yer know.

This was all hand crafted from scratch with reclaimed materials.

Gord knows what you think of the coffee table.

Attachments

I'll be honest - I think the nuts and bolts on the coffee table legs lets it down...

D

Deleted member 294929

You misunderstand - this is not taking the pee, this is fraternal appreciation - here's my curtain rail:

I have actually patented this design.

D

Deleted member 294929

I have actually patented this design.

You misunderstand - this is not taking the pee, this is fraternal appreciation - here's my curtain rail:

- Joined

- 11 Dec 2012

- Messages

- 4,543

- Reaction score

- 2,262

- Country

Will get more creative with my copper creations.

View attachment 335737

I'm thinking or key hanger next.

Is the gallows next door?

D

Deleted member 294929

Is the gallows next door?

The Richardsons.

D

Deleted member 294929

You could hang joints of meat from it...

And we do.

- Joined

- 22 Aug 2006

- Messages

- 7,160

- Reaction score

- 1,219

- Country

Just musin,,, if you got some rollers turned up (wood would do) or filled the pipe full of sand, and got bending right, you could do well making curtain rails for bay windows.

If you have a pillar drill you could use it as a press. Move the pipe back and forth over two padded wood blocks a foot or two apart, and press down in the middle with another padded block, a few millimeters. It would spring back of course, but without the padding you could use the setup to measure the deflection. Match the radius of curve with that of the bay .

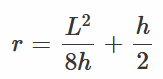

where is chord length, h is deflection.

So if you have a 4m bay with 2 foot of depth, you need to set a half inch of deflection with your blocks 600mm apart. Ish.

if you wanted to do posh, and avoid problems with the corrosion of the copper, you could use chromed tube and munsens.

If you have a pillar drill you could use it as a press. Move the pipe back and forth over two padded wood blocks a foot or two apart, and press down in the middle with another padded block, a few millimeters. It would spring back of course, but without the padding you could use the setup to measure the deflection. Match the radius of curve with that of the bay .

where is chord length, h is deflection.

So if you have a 4m bay with 2 foot of depth, you need to set a half inch of deflection with your blocks 600mm apart. Ish.

if you wanted to do posh, and avoid problems with the corrosion of the copper, you could use chromed tube and munsens.

i 100% love the use off materials for"interesting"and other uses and a coat rail is brilliant

bbbbuuuttt just keep in mind the screws are likely to be no6 or 7 or 3.5mm in those brackets and the load will be perhaps 50-100% times the weight off pipe and water so top screw is a weak point so perhaps a drill out to 4-4.5mm and brown plug would be safer

but just my thoughts

bbbbuuuttt just keep in mind the screws are likely to be no6 or 7 or 3.5mm in those brackets and the load will be perhaps 50-100% times the weight off pipe and water so top screw is a weak point so perhaps a drill out to 4-4.5mm and brown plug would be safer

but just my thoughts

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local