Hey,

Got a few DIY projects coming up; AV Unit, shoe rack and narrow bookshelf (for cookery books). Material is 18mm MDF.

Last time (AV unit), I did mitred corners with glue and screws for the outer carcase, and normal butt joints with glue and screws (edge to face, no joinery at all) for the internal shelves. Seemed to hold together really well.

This time, fancy trying something different. The shoe rack and bookshelf I'm not really worried about as the bookshelf shelves will probably only be 300mm wide.

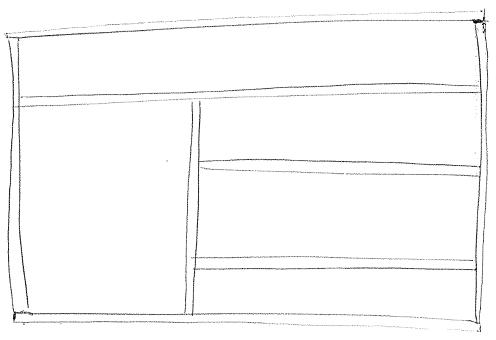

For the AV unit, the outer dimension is 900mm wide by 650mm high. The plan is to have 1 long shelf near the top, with a vertical separator below it, about 364mm in from the left edge (so supporting this long shelf). Then they'll be 2 shelves from this vertical piece to the right, meaning about 500mm long shelves.

As it will slot into an unused fireplace, I wasn't planning on having a back - I can't anyway as power, satellite, speaker and network points are all chased in here. Yes at the back of the chimney breast! Racking shouldn't be an issue as it won't be able to move left/right, up/down etc.

The unit will mostly be fixed, with exception of the 2 short shelves on the right, which I planned on using kitchen cupboard peg things with positioned vertical holes.

My idea was to use dowels (or biscuits) and glue to assemble. How would that work with MDF?

http://www.diy.com/nav/fix/nails-sc...5-H-3-x-W-0-6-x-D-0-6cm-9370654?skuId=9671359

PS: If I used dowels, rather than drilling a bit into the material to create a pocket, I would go all the way through. You won't see the dowels from the outside. Good or bad idea?

Got a few DIY projects coming up; AV Unit, shoe rack and narrow bookshelf (for cookery books). Material is 18mm MDF.

Last time (AV unit), I did mitred corners with glue and screws for the outer carcase, and normal butt joints with glue and screws (edge to face, no joinery at all) for the internal shelves. Seemed to hold together really well.

This time, fancy trying something different. The shoe rack and bookshelf I'm not really worried about as the bookshelf shelves will probably only be 300mm wide.

For the AV unit, the outer dimension is 900mm wide by 650mm high. The plan is to have 1 long shelf near the top, with a vertical separator below it, about 364mm in from the left edge (so supporting this long shelf). Then they'll be 2 shelves from this vertical piece to the right, meaning about 500mm long shelves.

As it will slot into an unused fireplace, I wasn't planning on having a back - I can't anyway as power, satellite, speaker and network points are all chased in here. Yes at the back of the chimney breast! Racking shouldn't be an issue as it won't be able to move left/right, up/down etc.

The unit will mostly be fixed, with exception of the 2 short shelves on the right, which I planned on using kitchen cupboard peg things with positioned vertical holes.

My idea was to use dowels (or biscuits) and glue to assemble. How would that work with MDF?

http://www.diy.com/nav/fix/nails-sc...5-H-3-x-W-0-6-x-D-0-6cm-9370654?skuId=9671359

PS: If I used dowels, rather than drilling a bit into the material to create a pocket, I would go all the way through. You won't see the dowels from the outside. Good or bad idea?