So here's one for the proper sparkies...

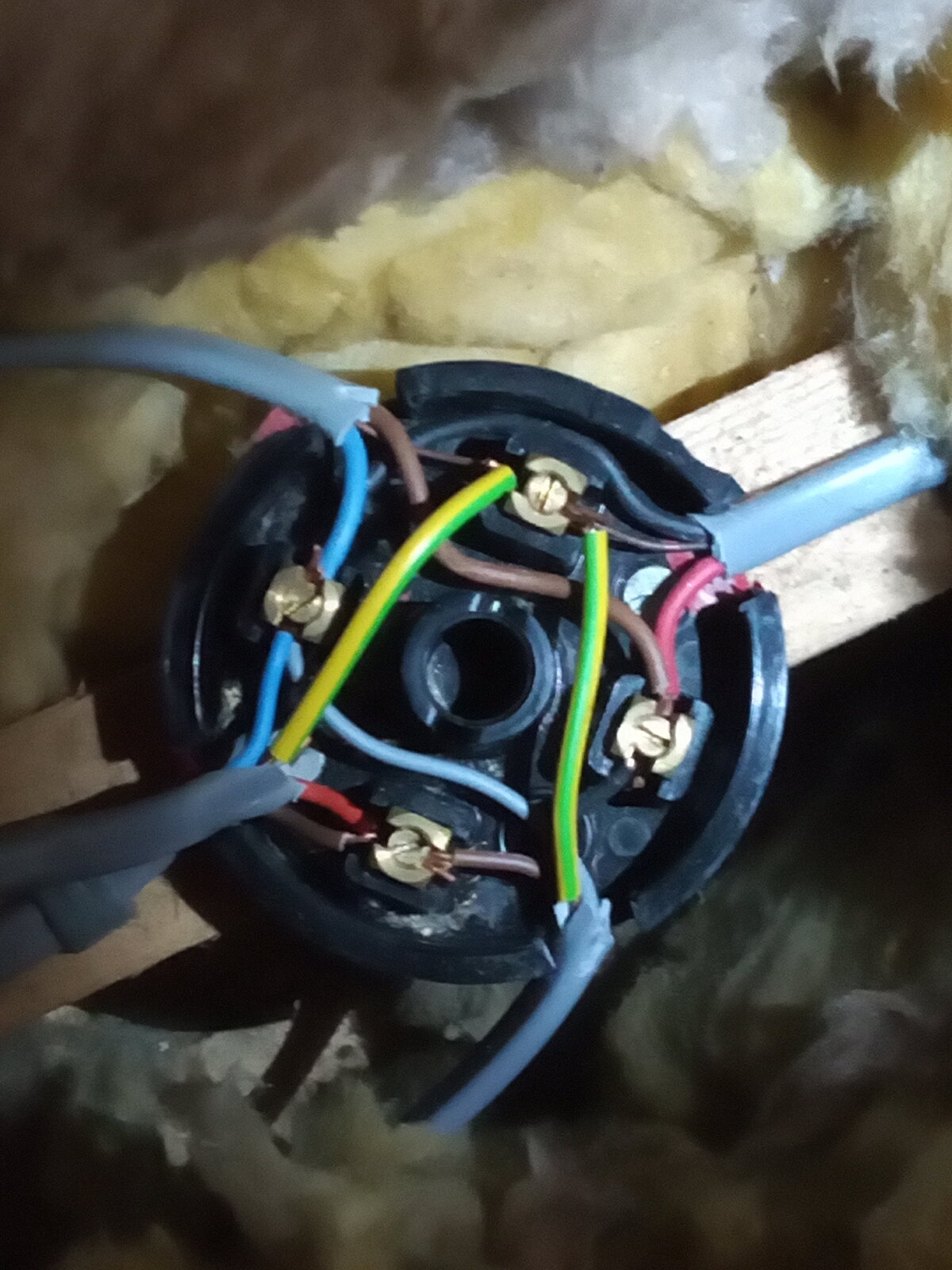

You're doing a bit of work in a house and while tracing a cable you come across a junction box which you open up.

Now, do you close it up and be on your way, tighten up those screws out of habit, go crazy with your torque screwdriver and tighten them to 1.2Nm, or replace it with Wagos and an enclosure?

You're doing a bit of work in a house and while tracing a cable you come across a junction box which you open up.

Now, do you close it up and be on your way, tighten up those screws out of habit, go crazy with your torque screwdriver and tighten them to 1.2Nm, or replace it with Wagos and an enclosure?