- Joined

- 27 Sep 2016

- Messages

- 6,209

- Reaction score

- 708

- Country

Hi all, ive got a few questions about welding steel beams.

Ive mentioned on previous posts il be doing a loft conversion soon and will be using 5.9 meter steel beams to support floor joists.

The beams are 203 x 203 x 46kg.

Each beam will be spliced into 2 peoces measuring about 1.9 meters each section. They will be joined using steel plates and 36 x m12 sheer proof bolts for each joint.

Now my structural engineer has advised this is suffient but would be good idea to get the joints welded as well.

Now ive just found out an old mate is a welder with 20 years experience welding car exhausts daily. He says he can weld the loft joists for me.

He has advised that the weld they use is stainless steel, and welded using a 1.5mm weld tip around the plates on the beam.

My question is, can you use stainless steel welds on steel rsj's? And would this be sufficiently strong to provide additional support to the loft floor?

Or is there another metalhe should use for the welds? The only other metal they use is mild steelwhich he says would be too weak.

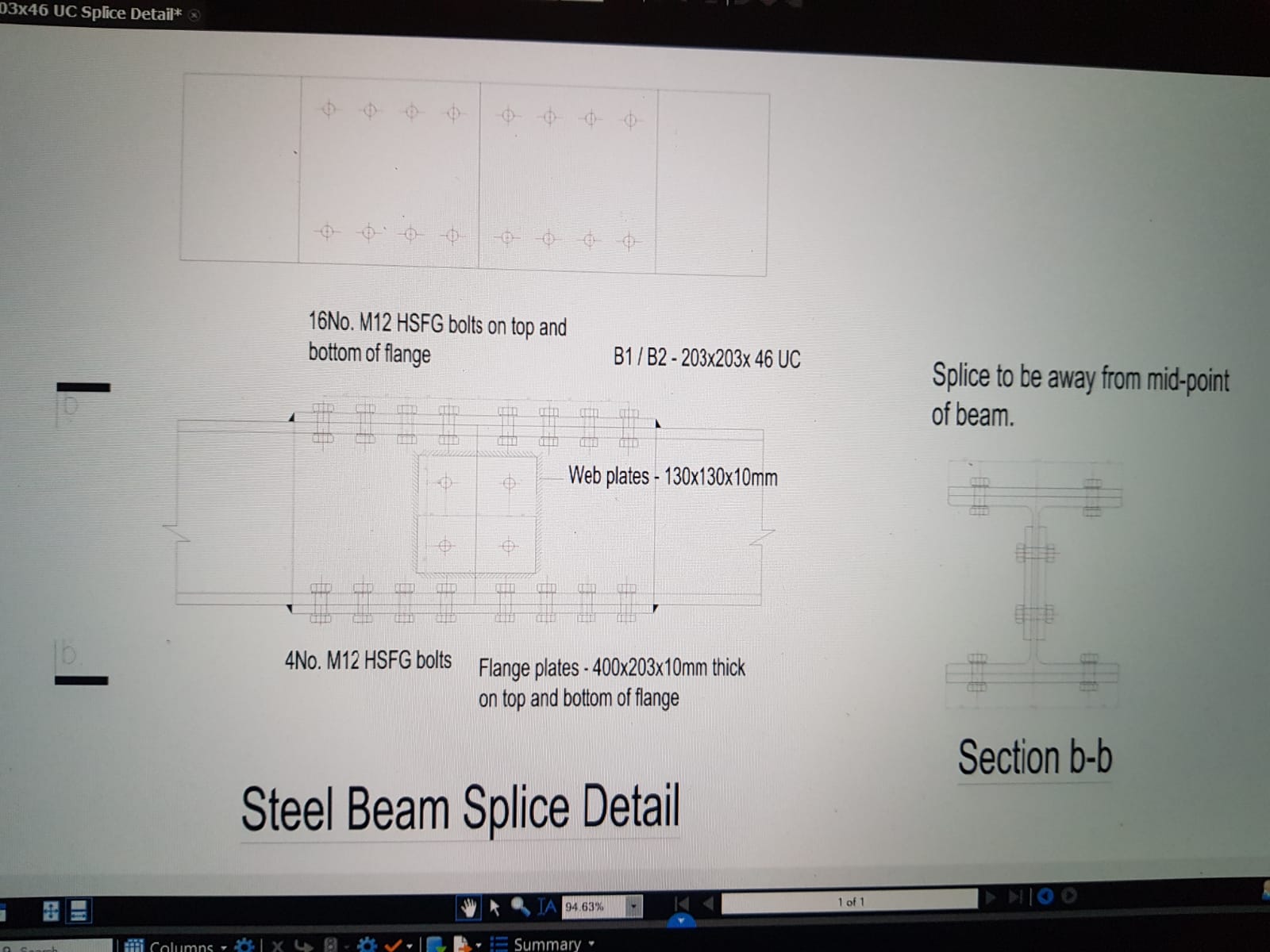

Heres picture of the joints on loft beams

Thanks in advance

Ive mentioned on previous posts il be doing a loft conversion soon and will be using 5.9 meter steel beams to support floor joists.

The beams are 203 x 203 x 46kg.

Each beam will be spliced into 2 peoces measuring about 1.9 meters each section. They will be joined using steel plates and 36 x m12 sheer proof bolts for each joint.

Now my structural engineer has advised this is suffient but would be good idea to get the joints welded as well.

Now ive just found out an old mate is a welder with 20 years experience welding car exhausts daily. He says he can weld the loft joists for me.

He has advised that the weld they use is stainless steel, and welded using a 1.5mm weld tip around the plates on the beam.

My question is, can you use stainless steel welds on steel rsj's? And would this be sufficiently strong to provide additional support to the loft floor?

Or is there another metalhe should use for the welds? The only other metal they use is mild steelwhich he says would be too weak.

Heres picture of the joints on loft beams

Thanks in advance