harger";p="2453328 said:So please tell me and those reading what the somewhat is, and how it will affect the masonary in this instance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Loft Steel bearing

- Thread starter Andy_J

- Start date

OK, so I should see a page thats titled 'Padstone Design and Analysis' or something to that effect, which I cant, how can he make assumptions - that would be very slack - I assume there is no 'span table' for Padstones to work from, and calculations must exist somewhere, my Calcs are in a 17pp document, so its not short - but nothing mentioning the beam bearings.

Looking at the party wall (1930's brick built) I can see what appear the ends of bricks several courses up from where I need to dog around - I assume these run at right angles - and the other end of the brick faces my neighbors loft space.

Looking at the party wall (1930's brick built) I can see what appear the ends of bricks several courses up from where I need to dog around - I assume these run at right angles - and the other end of the brick faces my neighbors loft space.

To arrive at the strength for the wall, you need to know the type of brick, type of mortar and the condition of the wall. I assume that no-one has carried out such an inspection?

I would suggest that the SE has used a low figure, one that will cover all eventualities, which will cost you less than him visiting to determine a more accurate value. The cost of padstones is relatively low, engineers time is quite expensive.

You can't really re-design this yourself, the loads will be factored and you need to ensure that the load cases are all combined with the correct load factors. We use Tedds and it's output isn't really designed for the layman.

He has probably used a figure of around 3N/mm² or so, but that has to be factored dependant upon the wall etc. I suggest you ring the number on the title block on the Tedds output, and ask the engineer who did the calcs if you can use a steel plate bearing, I doubt the Architect will know, it's not his discipline.

The ends of the bricks are header courses, I would assume that the wall is a 9" solid construction wall in English bond, 3 or 5 rows of stretchers and then a row of headers.

Our house is similar, cavity to the loft and then solid for the dividing wals and gable.

I would suggest that the SE has used a low figure, one that will cover all eventualities, which will cost you less than him visiting to determine a more accurate value. The cost of padstones is relatively low, engineers time is quite expensive.

You can't really re-design this yourself, the loads will be factored and you need to ensure that the load cases are all combined with the correct load factors. We use Tedds and it's output isn't really designed for the layman.

He has probably used a figure of around 3N/mm² or so, but that has to be factored dependant upon the wall etc. I suggest you ring the number on the title block on the Tedds output, and ask the engineer who did the calcs if you can use a steel plate bearing, I doubt the Architect will know, it's not his discipline.

The ends of the bricks are header courses, I would assume that the wall is a 9" solid construction wall in English bond, 3 or 5 rows of stretchers and then a row of headers.

Our house is similar, cavity to the loft and then solid for the dividing wals and gable.

I would suggest that the SE has used a low figure, one that will cover all eventualities, which will cost you less than him visiting to determine a more accurate value. The cost of padstones is relatively low, engineers time is quite expensive.

Paul; I assume your response was to the post immediately before yours by Frank999. If I remember correctly from a previous post of his, one of his padstones was specified as 900 long, which is ridiculous

Let's consider the figures; assuming the engineer had assumed a very low figure for the compressive strength of the masonry units, say AAC block at 2.8N/mm2, in class III mortar. The characterisitic compressive strength at most would be 1.5 x 2.8/3.5 = 1.2N/mm2.

With a padstone of 90,000 mm2, this would imply a factored load of 75kN from the beam. Do you seriously think that you get loads like that in a domestic loft conversion?

Also, how does a length of 900 fit in with the assumed 45 degree spread from the base of the beam? Must be a very wide flange!

This engineer also specfiied 6 steel beams - for a loft!! The engineer is supposed to provide a safe, yet practical and economic solution to the problem. To my mind, what we have here is not engineering, it's laziness. Perhaps if more engineers returned to doing calcs by hand, instead of putting unnecessarily inflated figures through a program, it might make them think a little more about what they are actually doing.

Ok - I had no idea there were 6 beams involved, unless it's a very difficult shape that's hard to understand. I also suspect the Architect/Engineer probably just made this up, I was trying to give the SE the benefit of the doubt.

The padstone, I think is laziness, but I know that Engineers often just stick oversize ones in rather than spend time and money designing down something that costs so little. Saving £10s on padstones by spending £100s on design isn't good practice, in a commercial environment, where a bit of plastering doesnt really affect overall costs.

I'll stick to the reply I've made twice, he should contact the SE and talk to him. That doesn't cost anything.

Yes, I agree hand calc's are a better way for simple structures, as are experienced people who know what they expect to see before they start. We have a young Thai lad a couple of years out of uni who is a wiz on all the Euro codes, and software but because he has no experience of what it should look like his designs are often way over the top. Sadly simple economics means that younger (cheaper) engineers do more work with less supervision and this is the sort of thing that results.

Don't get me started on draughtsmen vs CAD operators and "project managers" who look like they should still be wearing shorts.

The padstone, I think is laziness, but I know that Engineers often just stick oversize ones in rather than spend time and money designing down something that costs so little. Saving £10s on padstones by spending £100s on design isn't good practice, in a commercial environment, where a bit of plastering doesnt really affect overall costs.

I'll stick to the reply I've made twice, he should contact the SE and talk to him. That doesn't cost anything.

Yes, I agree hand calc's are a better way for simple structures, as are experienced people who know what they expect to see before they start. We have a young Thai lad a couple of years out of uni who is a wiz on all the Euro codes, and software but because he has no experience of what it should look like his designs are often way over the top. Sadly simple economics means that younger (cheaper) engineers do more work with less supervision and this is the sort of thing that results.

Don't get me started on draughtsmen vs CAD operators and "project managers" who look like they should still be wearing shorts.

I would suspect that for typical domestic work, there are only a few types of beams and a narrow range of padstones and plates for most situations.

Someone should come up with some tables or something in a ready-reckoner

Someone should come up with some tables or something in a ready-reckoner

I spoke to the SE, I found a 50pp document he'd sent through my 'architect', he felt Steel plates were not the way to go, he quoted UDO bending resistances would be unknown - what ever they are.

On the back page are some numbers for padstones, the 900mm padstone is:

B3

Reaction kn: 36.2

Dimensions: 900x100x150h

stress n/m: 20.40

On one of the front pages B3 is:

Span: 4.5mt

Floor Load + (some scribble DNU ?? not sure):

D = 2.8x1 +0.7 = 3.5kn/m

L = 2.8x1.5 = 4.2kn/m

Studs S1:

D = 3.7x0.9/2.8 = 1.2kn/m

L = 1.5x0.9/2.8 = 0.5kn/m

Total UDL:

D=4.7kn/m

L=4.7kn/m

Point Load L1

D=10.4 kn/m }

L=6.5 kn/m } 4m

Regarding the Mortar mix for filling in around the ends of the steels, I'm sure I've read the term 'drypack' - somewhere on one of my plans, but cant find it now, the structural calcs state:

'all masonary above ground to be constructed in 1:1:6 mortar'

is that what that refers to, I assume its one part Lime, one part cement and six building sand ?

From what I understand its to be mixed as dry as possible to avoid shrinkage.

What should the padstones be bedded in, the same ?

I'm considering using this company to supply the steels and do the fabrication:

www.ainscoughmetals.co.uk

The steels are second hand, the quotes about half the cost of new, is there anything I should question regarding this - ie how do i know the fabrication is to BS5950 & BS5135 etc.

I'm considering doing the application of Zinc Phospate Primer, wire cup brush on an electric drill, 2 coats, 10L for about £25, as opposed to £200 for them to do it.

On the back page are some numbers for padstones, the 900mm padstone is:

B3

Reaction kn: 36.2

Dimensions: 900x100x150h

stress n/m: 20.40

On one of the front pages B3 is:

Span: 4.5mt

Floor Load + (some scribble DNU ?? not sure):

D = 2.8x1 +0.7 = 3.5kn/m

L = 2.8x1.5 = 4.2kn/m

Studs S1:

D = 3.7x0.9/2.8 = 1.2kn/m

L = 1.5x0.9/2.8 = 0.5kn/m

Total UDL:

D=4.7kn/m

L=4.7kn/m

Point Load L1

D=10.4 kn/m }

L=6.5 kn/m } 4m

Regarding the Mortar mix for filling in around the ends of the steels, I'm sure I've read the term 'drypack' - somewhere on one of my plans, but cant find it now, the structural calcs state:

'all masonary above ground to be constructed in 1:1:6 mortar'

is that what that refers to, I assume its one part Lime, one part cement and six building sand ?

From what I understand its to be mixed as dry as possible to avoid shrinkage.

What should the padstones be bedded in, the same ?

I'm considering using this company to supply the steels and do the fabrication:

www.ainscoughmetals.co.uk

The steels are second hand, the quotes about half the cost of new, is there anything I should question regarding this - ie how do i know the fabrication is to BS5950 & BS5135 etc.

I'm considering doing the application of Zinc Phospate Primer, wire cup brush on an electric drill, 2 coats, 10L for about £25, as opposed to £200 for them to do it.

I spoke to the SE, I found a 50pp document he'd sent through my 'architect', he felt Steel plates were not the way to go, he quoted UDO bending resistances would be unknown - what ever they are.

On the back page are some numbers for padstones, the 900mm padstone is:

B3

Reaction kn: 36.2

Dimensions: 900x100x150h

stress n/m: 20.40

On one of the front pages B3 is:

Span: 4.5mt

Floor Load + (some scribble DNU ?? not sure):

D = 2.8x1 +0.7 = 3.5kn/m

L = 2.8x1.5 = 4.2kn/m

Studs S1:

D = 3.7x0.9/2.8 = 1.2kn/m

L = 1.5x0.9/2.8 = 0.5kn/m

Total UDL:

D=4.7kn/m

L=4.7kn/m

Point Load L1

D=10.4 kn/m }

L=6.5 kn/m } 4m

What section-size is B3?

OK, a 36.2kN load on a 900x100 bearing gives a stress of:

(36.2 x 10 ³)/(900x100) = 0.402 N/mm ²

Allowable stress:

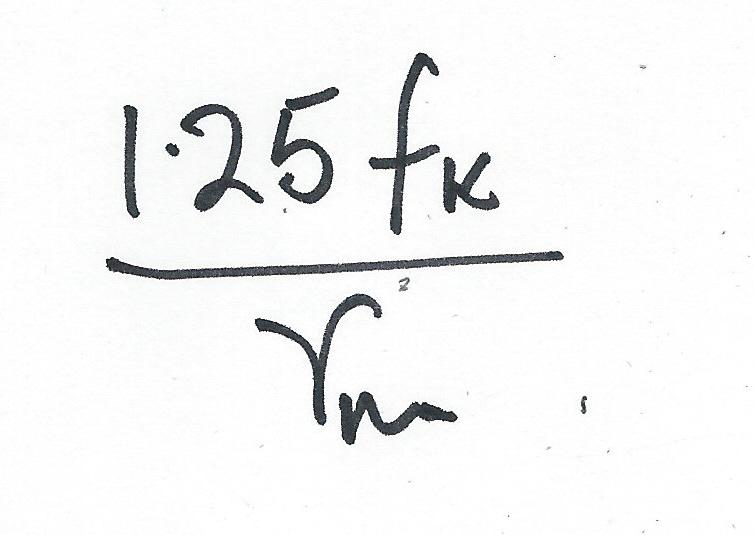

Assume worst case of 5N brick in M2 mortar, fk = 2.2N/mm ² .

Assume worst case partial safety factors gives:

fb = 1.25 x 2.2 / 3.5 = 0.786 N/mm ²

As you can see, the allowble stress is almost double the applied stress.

So...

Area of bearing required for a load of 36.2kN

36.2 x 10 ³ / 0.786 = 46702mm ²

You need a 550x100x300 high mass concrete padstone.

Or if you can, make it 440x110x215 high.

Use prestressed concrete lintels and they will be OK at 140mm high.

As for the calc on steel bearing plates, the calc is simple for an SE.

Simply take the maximum allowable stress (or reduce it slightly), and treat the plate as two cantilevers from the centre of the beam (the flange can also be taken into account). Then work out the bending moment. Choose a plate thickness that has sufficient capacity to withstand this bending moment, but also look to keep deflections to an absolute minimum.

A 500mm x 100mm x 20mm thk plate would be sufficient for a load of 36.2kN on 5N brick in M2 mortar.

(36.2 x 10 ³)/(900x100) = 0.402 N/mm ²

Allowable stress:

Assume worst case of 5N brick in M2 mortar, fk = 2.2N/mm ² .

Assume worst case partial safety factors gives:

fb = 1.25 x 2.2 / 3.5 = 0.786 N/mm ²

As you can see, the allowble stress is almost double the applied stress.

So...

Area of bearing required for a load of 36.2kN

36.2 x 10 ³ / 0.786 = 46702mm ²

You need a 550x100x300 high mass concrete padstone.

Or if you can, make it 440x110x215 high.

Use prestressed concrete lintels and they will be OK at 140mm high.

As for the calc on steel bearing plates, the calc is simple for an SE.

Simply take the maximum allowable stress (or reduce it slightly), and treat the plate as two cantilevers from the centre of the beam (the flange can also be taken into account). Then work out the bending moment. Choose a plate thickness that has sufficient capacity to withstand this bending moment, but also look to keep deflections to an absolute minimum.

A 500mm x 100mm x 20mm thk plate would be sufficient for a load of 36.2kN on 5N brick in M2 mortar.

The section is 203x203x46uc.

The Cover Sheet on the Structural Calcs states a Name as:

Blah Blah Associates

Architects and Structural Engineers

London EC1

The website and some of the jobs look very upmarket, houses and commercial, its a RIBA chartered practice of 10 Architects.

I guess if your used to working for upmarket clients, you'll specify the best, but I just have a lowly loft extension. I cant work out why my 'Architect/building control inspector - bloke who's handy with autocad would be using them for such a project as mine. Surely it just requires a self employed person with enough skills/qualifications to calculate a relatively simple little job, correct me if I'm wrong.

I've now looked through all the pages of the structural calcs and see that all the joists have been specified as C24 !! one beam for example being a floor joist (no stud or purlin walls to support):

200x50

400mm spacing

Span 2700mm

Its spec'd as C24, dead load of 1kN/m2, Imposed UDL 1.5kN/m2

I've found a BSW Timber C16 span table:

Dead load kN/m2 excluding self weight of joist: 0.75 - 1.25kN/m2

Joist Size: 195x45mm

Gives an allowable span of 3484mm, surely then a C16 would be more than sufficient.

(as a side question - I assume BC will be OK with timbers being 195x45, as opposed to 200x50mm ??, why the difference, is that something to do with the need to 'regularise' timber once on site -which I dont see myself doing

Any thoughts on the bedding mortar designation ?

Thanks

The Cover Sheet on the Structural Calcs states a Name as:

Blah Blah Associates

Architects and Structural Engineers

London EC1

The website and some of the jobs look very upmarket, houses and commercial, its a RIBA chartered practice of 10 Architects.

I guess if your used to working for upmarket clients, you'll specify the best, but I just have a lowly loft extension. I cant work out why my 'Architect/building control inspector - bloke who's handy with autocad would be using them for such a project as mine. Surely it just requires a self employed person with enough skills/qualifications to calculate a relatively simple little job, correct me if I'm wrong.

I've now looked through all the pages of the structural calcs and see that all the joists have been specified as C24 !! one beam for example being a floor joist (no stud or purlin walls to support):

200x50

400mm spacing

Span 2700mm

Its spec'd as C24, dead load of 1kN/m2, Imposed UDL 1.5kN/m2

I've found a BSW Timber C16 span table:

Dead load kN/m2 excluding self weight of joist: 0.75 - 1.25kN/m2

Joist Size: 195x45mm

Gives an allowable span of 3484mm, surely then a C16 would be more than sufficient.

(as a side question - I assume BC will be OK with timbers being 195x45, as opposed to 200x50mm ??, why the difference, is that something to do with the need to 'regularise' timber once on site -which I dont see myself doing

Any thoughts on the bedding mortar designation ?

Thanks

If the bottom flange of B3 is 203 wide, the 900 padstone would be too long. The ends of the padstone would be outside the 45 degree load spread from the flange, and would possibly be in tension. However, Mr Raygun has given more realistic figures for a pad in his post.

The 200x50 c24 joists are way too big; 150 x 50 C16s would be fine on 2.7m span.

The 200x50 c24 joists are way too big; 150 x 50 C16s would be fine on 2.7m span.

I'd love to know how on a simple little job everything has been so over spec'd - at the end of the day its just a loft floor ... thank you for your calcs - at this stage the cost of having everything recalculated out weighs thje extra work and cost of the bearings, but the cost of all the steels is quite a consideration.

So for that joist a C16 200x50 would suffice ? why have they spec'd C24 if there is no need ??

So for that joist a C16 200x50 would suffice ? why have they spec'd C24 if there is no need ??

I'm pretty certain I've worked out who the Structural Engineer on your job is...not going to mention their name, as you haven't, but they do look like they should know what they are doing. As you say though, why has your designer subbed out the work to them...they don't look like they would be the best value sub contractor...The section is 203x203x46uc.

The Cover Sheet on the Structural Calcs states a Name as:

Blah Blah Associates

Architects and Structural Engineers

London EC1

They haven't specified the best, they've simply overspecced. No need to specify anything other than what is sufficient for the brief, regardless of the client.I guess if your used to working for upmarket clients, you'll specify the best, but I just have a lowly loft extension.

Yes a poor choice to sub to, I'm sure there are self employed Structural Engineers much better suited - who would have a better feel for such a job.

Should I question them regarding the Joists being C24, from my calculations C24's are 20% more expensive - in addition to the problem of suppliers not keeping these in stock.

If I can prove, through the use of Span Tables - to my BC officer that only C16's are needed would he be happy without requiring new calcs from the structural engineers ?

Is there any argument for over specifying ? if not then thats a mistake surely, even myself being a laymen has worked out I only need C16's, surely if there is a reason I should have been consulted before it went to planning ...

Should I question them regarding the Joists being C24, from my calculations C24's are 20% more expensive - in addition to the problem of suppliers not keeping these in stock.

If I can prove, through the use of Span Tables - to my BC officer that only C16's are needed would he be happy without requiring new calcs from the structural engineers ?

Is there any argument for over specifying ? if not then thats a mistake surely, even myself being a laymen has worked out I only need C16's, surely if there is a reason I should have been consulted before it went to planning ...

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 5

- Views

- 14K

- Replies

- 30

- Views

- 20K

- Replies

- 5

- Views

- 3K

- Replies

- 1

- Views

- 2K