- Joined

- 24 Sep 2005

- Messages

- 6,345

- Reaction score

- 269

- Country

Guessing is not good - You need to picture the process, or using cad with solids capability add a solid cylinder to your solid cube, centre line coincident with the line between diametrically opposite cube corners.

The cylinder should be longer than the distance twixt cube corners in question.

Subtract the cylinder from the cube, interrogate the properties of the cube remaining read the volume. Compare to 1000 CC.

Calculating is a bit laborious but achievable without higher math.

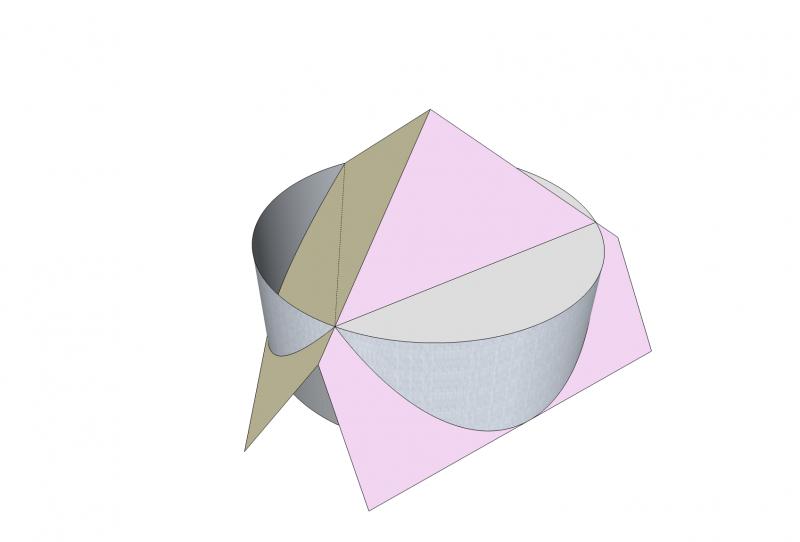

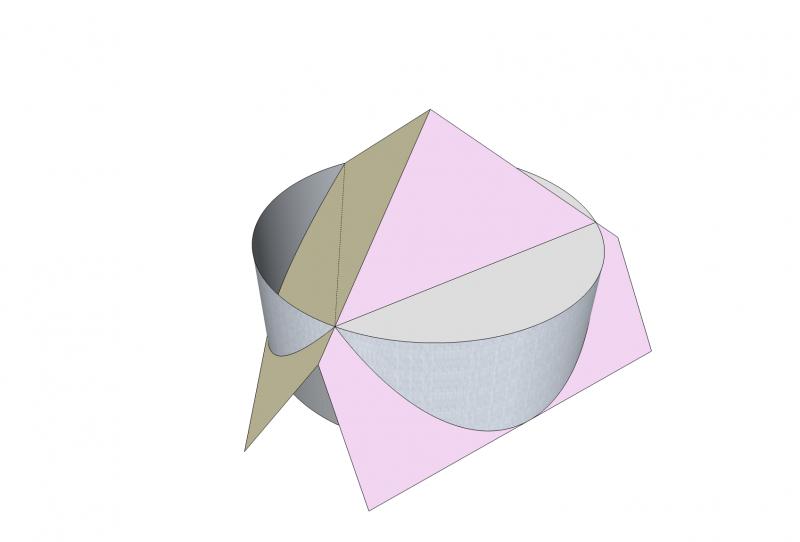

Just need to picture the process. As the cutting tool eg. a flat ended milling cutter begins cutting the first peak of a corner 'pyramid' the resultant csa is triangular, as the cut progresses the triangle increases in length of side, then the cutter full diameter is cutting the three cube edges, the triangular csa is at a max - thus the base of pyramid in question.

As the cutter proceeds along it's path the csa begins growing radii propagating from what was the triangle corners.

when the growing radii come together and the cutter is working full face it will be machining a full cylinder until starting to break out from the sides at the opposite cube faces.

Need to calc. 'pyramid vol' x 2

From base of first pyramid to base of the second pyramid we can calc' a full cylinder, BUT we have the three 'fresh air' pockets (cylindrical wedges) as the cutter is approaching and entering full diameter cutting, these occur in the vicinity of both cube corners (http://mathworld.wolfram.com/CylindricalWedge.html)

So having calced this cylinder's vol including the wedges - If we subtract the volumes of the six wedges from the cylinder we have the material removed between the bases of the two pyramids add this to the vols of the pyramids and voila you have the volume removed.

-0-

The cylinder should be longer than the distance twixt cube corners in question.

Subtract the cylinder from the cube, interrogate the properties of the cube remaining read the volume. Compare to 1000 CC.

Calculating is a bit laborious but achievable without higher math.

Just need to picture the process. As the cutting tool eg. a flat ended milling cutter begins cutting the first peak of a corner 'pyramid' the resultant csa is triangular, as the cut progresses the triangle increases in length of side, then the cutter full diameter is cutting the three cube edges, the triangular csa is at a max - thus the base of pyramid in question.

As the cutter proceeds along it's path the csa begins growing radii propagating from what was the triangle corners.

when the growing radii come together and the cutter is working full face it will be machining a full cylinder until starting to break out from the sides at the opposite cube faces.

Need to calc. 'pyramid vol' x 2

From base of first pyramid to base of the second pyramid we can calc' a full cylinder, BUT we have the three 'fresh air' pockets (cylindrical wedges) as the cutter is approaching and entering full diameter cutting, these occur in the vicinity of both cube corners (http://mathworld.wolfram.com/CylindricalWedge.html)

So having calced this cylinder's vol including the wedges - If we subtract the volumes of the six wedges from the cylinder we have the material removed between the bases of the two pyramids add this to the vols of the pyramids and voila you have the volume removed.

-0-