Hi,

I'm in the process of fitting our Mira Excel Built in shower valve.

I've chased our plaster/brick wall in accordance with the installation instructions, ie 58mm deep, 145mm high, 245mm wide, here is a picture (I haven't chased the outlet pipe yet, which will be going upwards)

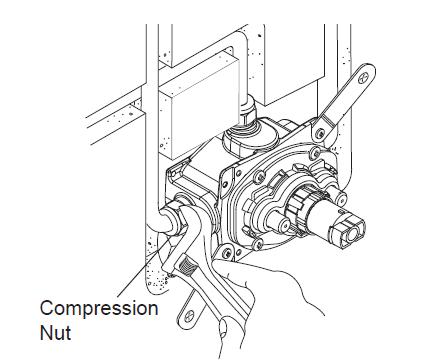

Here is a picture of the valve in the hole.

I've also made a couple of mock-up 90° elbows for the inlet pipes. However, I can only insert the pipes into with the valve while the valve is outside of the hole. If I put the valve into the hole first, there simply isn't enough room on either side to insert the pipes. Is this normal?

As I see it, I've got 3 options

1. Hope I never need to remove the entire valve for maintenance or replacement at some point in the future.

2. Widen the hole about an extra 7mm on each side.

3. Use a 90° street elbow with an olive fitting on it, so that my 90° bends are much tighter, like one ones shown in Mira's installation instructions, here is their picture.

However putting olives on street elbows seems to be frowned upon by many on here (see //www.diynot.com/forums/viewtopic.php?t=132554&start=0).

So what would you do?

Thanks in advance.

I'm in the process of fitting our Mira Excel Built in shower valve.

I've chased our plaster/brick wall in accordance with the installation instructions, ie 58mm deep, 145mm high, 245mm wide, here is a picture (I haven't chased the outlet pipe yet, which will be going upwards)

Here is a picture of the valve in the hole.

I've also made a couple of mock-up 90° elbows for the inlet pipes. However, I can only insert the pipes into with the valve while the valve is outside of the hole. If I put the valve into the hole first, there simply isn't enough room on either side to insert the pipes. Is this normal?

As I see it, I've got 3 options

1. Hope I never need to remove the entire valve for maintenance or replacement at some point in the future.

2. Widen the hole about an extra 7mm on each side.

3. Use a 90° street elbow with an olive fitting on it, so that my 90° bends are much tighter, like one ones shown in Mira's installation instructions, here is their picture.

However putting olives on street elbows seems to be frowned upon by many on here (see //www.diynot.com/forums/viewtopic.php?t=132554&start=0).

So what would you do?

Thanks in advance.