- Joined

- 13 Jan 2016

- Messages

- 12

- Reaction score

- 0

- Country

Hi guys.

We have a new external Worcester Danesmoor 18/25 kw System Oil Boiler.

The whole system is brand new, radiators and a un-vented 210 litre domestic hot water cylinder.

With all the radiators on full (the hot water cylinder valve is turned off for the moment. The kitchen and bathroom are not finished.)

After about 25 minutes the return flow on the heating circuit is hot enough to turn off the boiler's internal stat.

So the burner stops heating even though the room stat is still calling for heat. (I know this is normal.)

The central heating pump keeps running and then two minutes later once the return flow has cooled enough the boiler fires up again.

It then burns for two minutes until the return flow is hot again and then it stops.

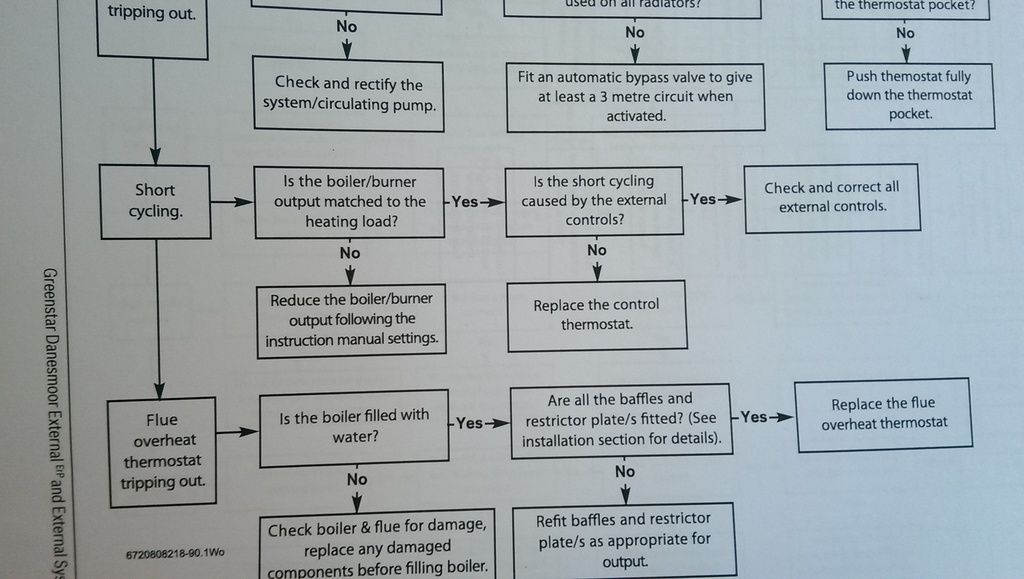

On, off, on, off in two minute intervals.

So, it's all working properly but the cycle is too short, am I right?

Am I right in thinking that I want it to be at least a ten minute cycle?

The engineer who commissioned the boiler for me put in the middle sized nozzle.

I think it needs the smaller sized to run at the minimum of 18kw. Am I right?

I think currently the heat source is oversized for the radiator output. (This will be different when I start heating the cylinder obviously.)

(The engineer did do all the heat loss calculations and specified the radiators for me to buy.)

He came over yesterday and adjusted the bypass valve pressure and bled some air out of the heat exchanger in the boiler. He was reluctant to change the nozzle for some reason.

It didn't change the short cycling at all.

Any thoughts guys?

(All my radiators have TRV's currently set to maximum. Once we move in though and adjust them I'm hoping that our wood burner in the open plan living area will cause a lot of the valves to close down meaning that the boilers heat will be being sent mostly to the back rooms only in which case the radiator output will be even less. Will this exasperate any short cycle problems?)

We have a new external Worcester Danesmoor 18/25 kw System Oil Boiler.

The whole system is brand new, radiators and a un-vented 210 litre domestic hot water cylinder.

With all the radiators on full (the hot water cylinder valve is turned off for the moment. The kitchen and bathroom are not finished.)

After about 25 minutes the return flow on the heating circuit is hot enough to turn off the boiler's internal stat.

So the burner stops heating even though the room stat is still calling for heat. (I know this is normal.)

The central heating pump keeps running and then two minutes later once the return flow has cooled enough the boiler fires up again.

It then burns for two minutes until the return flow is hot again and then it stops.

On, off, on, off in two minute intervals.

So, it's all working properly but the cycle is too short, am I right?

Am I right in thinking that I want it to be at least a ten minute cycle?

The engineer who commissioned the boiler for me put in the middle sized nozzle.

I think it needs the smaller sized to run at the minimum of 18kw. Am I right?

I think currently the heat source is oversized for the radiator output. (This will be different when I start heating the cylinder obviously.)

(The engineer did do all the heat loss calculations and specified the radiators for me to buy.)

He came over yesterday and adjusted the bypass valve pressure and bled some air out of the heat exchanger in the boiler. He was reluctant to change the nozzle for some reason.

It didn't change the short cycling at all.

Any thoughts guys?

(All my radiators have TRV's currently set to maximum. Once we move in though and adjust them I'm hoping that our wood burner in the open plan living area will cause a lot of the valves to close down meaning that the boilers heat will be being sent mostly to the back rooms only in which case the radiator output will be even less. Will this exasperate any short cycle problems?)