I've got my assessment date through for my NICEIC DI assessment, can anyone give me any clues as to what to expect ?

I'm guessing on retesting at least part of the installation (my major job is a CU change), checking my knowledge of testing and understanding the results seen..........

I've got all my exam certs, insurance, EIC's, MWC's and LABC docs, etc etc etc together. A copy of Part P regs, EAW regs, 16&17th regs books etc etc

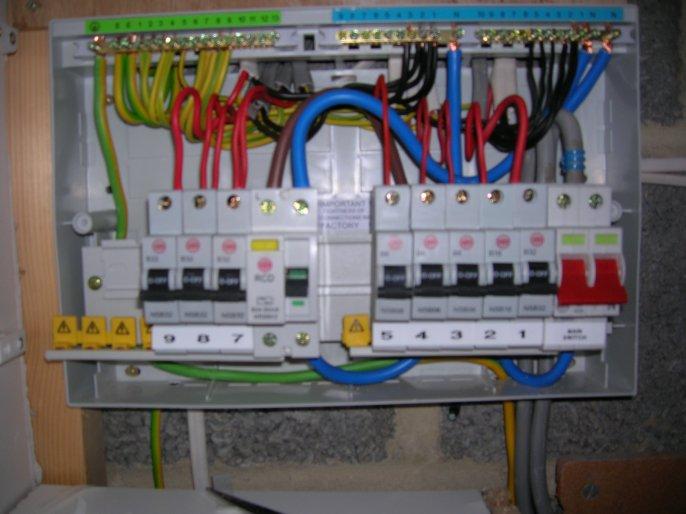

Heres a piccy of my completed board change done Nov last year (so 16th ed) the main thing I'm not really happy with is the amount of copper on the main neutral connections to the bar but the terminals are soooo tight (factory tightened)I didn't want to damage them trying to undo them to redo the terminations

Any tips/hints gratefully recieved !

I'm guessing on retesting at least part of the installation (my major job is a CU change), checking my knowledge of testing and understanding the results seen..........

I've got all my exam certs, insurance, EIC's, MWC's and LABC docs, etc etc etc together. A copy of Part P regs, EAW regs, 16&17th regs books etc etc

Heres a piccy of my completed board change done Nov last year (so 16th ed) the main thing I'm not really happy with is the amount of copper on the main neutral connections to the bar but the terminals are soooo tight (factory tightened)I didn't want to damage them trying to undo them to redo the terminations

Any tips/hints gratefully recieved !