New here, first post. Basic issue = rads only heat when I am actively draining the rad return line to the outside of the house.

First, the lay of the land...

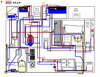

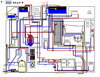

1800 or earlier stone built coach house. Three floors, Ground Floor, 1st Floor, Finished Attic. Open vented/Indirect system. Wood-fired back boiler Stanley 8 stove in the kitchen. Directly next to it is a Grundfos UP20 -14BX circulation pump in the return line from the rads connected to a pipe stat on the hot feed line. Ground floor has one rad in the kitchen and one rad in the living room. 1st floor has three bedrooms (two with rads), a toilet and a separate family bath with tub, shower, rad and sink/basin. Also on the first floor is the hot press with the immersion tank and above that the high cistern for the toilet and the feed and expansion cistern for the rads which are actually at attic/loft level. The finished attic has two rooms (one with a rad, the second will be getting a rad later) and the cold water secondary cistern.

The problem...

Since we moved in a year ago we've had intermittent heating on the first floor. The attic has never had a rad installed until now. And the ground floor has worked quite well. Last week we heard some humming from the Grundfos pump which I found not-so-conveniently located behind the kitchen cabinet! We began to notice the rads were cold. I thought the pump took a dump. But, figuring I had to buy a new one anyway, I removed it and disassembled it after a few short courses in plumbing from YouTube Technical Institute. The pump seems to be working fine. It spins freely and the thermostat starts and stops it running. So I reinstalled it. After installing it I thought all was well. But after about 15 minutes there was no heat again in the rads. After many more vidoes and searching forums, especially this one, and trying to bleed and balance the rads I'm stumped. The rads ONLY get warm or hot when I am actively draining the return line below the pump out to the exterior of the house. Within 15 minutes the exposed copper lines in the kitchen and the rads are all cold again. I removed and flushed the kitchen and living room rads.

Sooo, any ideas?

Some other hints...

The bathroom rad is intermittently hot even when the kitchen fire has been blazing for an hour. There is so much steam backing up through the system that I had to pipe the vent out from the F&E cistern to outside the window because it was blowing water all around the cistern cabinet above the toilet causing water the leak through the hall light fixture!!!

First, the lay of the land...

1800 or earlier stone built coach house. Three floors, Ground Floor, 1st Floor, Finished Attic. Open vented/Indirect system. Wood-fired back boiler Stanley 8 stove in the kitchen. Directly next to it is a Grundfos UP20 -14BX circulation pump in the return line from the rads connected to a pipe stat on the hot feed line. Ground floor has one rad in the kitchen and one rad in the living room. 1st floor has three bedrooms (two with rads), a toilet and a separate family bath with tub, shower, rad and sink/basin. Also on the first floor is the hot press with the immersion tank and above that the high cistern for the toilet and the feed and expansion cistern for the rads which are actually at attic/loft level. The finished attic has two rooms (one with a rad, the second will be getting a rad later) and the cold water secondary cistern.

The problem...

Since we moved in a year ago we've had intermittent heating on the first floor. The attic has never had a rad installed until now. And the ground floor has worked quite well. Last week we heard some humming from the Grundfos pump which I found not-so-conveniently located behind the kitchen cabinet! We began to notice the rads were cold. I thought the pump took a dump. But, figuring I had to buy a new one anyway, I removed it and disassembled it after a few short courses in plumbing from YouTube Technical Institute. The pump seems to be working fine. It spins freely and the thermostat starts and stops it running. So I reinstalled it. After installing it I thought all was well. But after about 15 minutes there was no heat again in the rads. After many more vidoes and searching forums, especially this one, and trying to bleed and balance the rads I'm stumped. The rads ONLY get warm or hot when I am actively draining the return line below the pump out to the exterior of the house. Within 15 minutes the exposed copper lines in the kitchen and the rads are all cold again. I removed and flushed the kitchen and living room rads.

Sooo, any ideas?

Some other hints...

The bathroom rad is intermittently hot even when the kitchen fire has been blazing for an hour. There is so much steam backing up through the system that I had to pipe the vent out from the F&E cistern to outside the window because it was blowing water all around the cistern cabinet above the toilet causing water the leak through the hall light fixture!!!