Hey all,

Working on a wall where the studs are old and just a mess. Aside from being twisted (which I planed flat as best I could), they're also not plumb and lean back a fair bit.

The simplest way to fix this would be to sister a whole new bunch of studs all plumb and job's done. That's the quick fix, but as I'm insulating I want to maximise the insulation, so doing it the hard way.

I don't have the skillset to rip full length timber wedges from studs to make a perfectly cut furring strip all the way top to bottom, so ruling that one out too.

So, last option seems to be shimming. I've measured about 5cm from the doorframe (since I don't have bottom plates in this old house to measure from) and shot a laser line (which I also squared with the adjacent wall since that was off too). This makes it much simpler as I can just keep referring to a tape measure and aim to hit the same measurement that the laser hits on the tape everywhere. Sadly, we don't have the easy rolls of felt/cardboard shims like they sell over in the US, so I've had to cut strips of hardboard and tack it to the face of the studs in layers to pack it out to get close to the laser line measurement. From there, I mark roughly where screws will go in (so every 300mm) and pack it up with either cardboard or plastic packers to ensure solid contact.

So far so good, I hope. However, what do I do with the spaces between each final packer? Want to avoid any situation in the future where the plasterboard could bow in those areas and deform (such as something being fixed to the wall over a small gap). Would using an adhesive that sets solid like gripfill or pinkgrip work? I'd just gun it in the gaps before screwing the plasterboard on and hopefully it spreads out and fills it all.

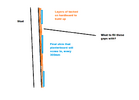

I've included an attached diagram that hopefully makes more sense.

Working on a wall where the studs are old and just a mess. Aside from being twisted (which I planed flat as best I could), they're also not plumb and lean back a fair bit.

The simplest way to fix this would be to sister a whole new bunch of studs all plumb and job's done. That's the quick fix, but as I'm insulating I want to maximise the insulation, so doing it the hard way.

I don't have the skillset to rip full length timber wedges from studs to make a perfectly cut furring strip all the way top to bottom, so ruling that one out too.

So, last option seems to be shimming. I've measured about 5cm from the doorframe (since I don't have bottom plates in this old house to measure from) and shot a laser line (which I also squared with the adjacent wall since that was off too). This makes it much simpler as I can just keep referring to a tape measure and aim to hit the same measurement that the laser hits on the tape everywhere. Sadly, we don't have the easy rolls of felt/cardboard shims like they sell over in the US, so I've had to cut strips of hardboard and tack it to the face of the studs in layers to pack it out to get close to the laser line measurement. From there, I mark roughly where screws will go in (so every 300mm) and pack it up with either cardboard or plastic packers to ensure solid contact.

So far so good, I hope. However, what do I do with the spaces between each final packer? Want to avoid any situation in the future where the plasterboard could bow in those areas and deform (such as something being fixed to the wall over a small gap). Would using an adhesive that sets solid like gripfill or pinkgrip work? I'd just gun it in the gaps before screwing the plasterboard on and hopefully it spreads out and fills it all.

I've included an attached diagram that hopefully makes more sense.