Hi guys,

Having finally had our sub floors laid we are in a position to start thinking about plumbing. Currently the only pipe work we have is a 15mm copper main through the kitchen wall (giving approx 22l/m), flow and return going to 1 rad in conservatory, pipe work for backboiler and all original pipework in the loft conversion and the old toilet soil pipes

Ive rang quite a few local plumbers but many are too busy (1-3month waits!), dont want a full house to do or dont know anything about thermal store systems .

.

So im thinking of having a go myself and get someone to make connections where required and commission everything when done (found a guy busy with new builds for next few months but willing to call in to keep me right and test everything)

and get someone to make connections where required and commission everything when done (found a guy busy with new builds for next few months but willing to call in to keep me right and test everything)

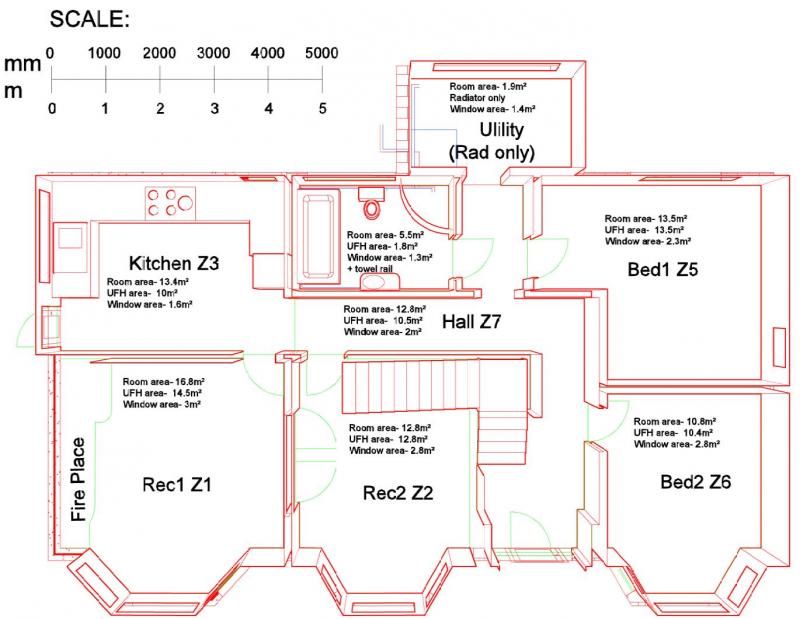

Its a bungalow with 2 rooms upstairs,

Water draws - me + other half, no kids for while

1 bath, 1 shower,1 hand basin,1 toilet, kitchen sink, wash machine.

Heating -

UFH throughout groundfloor, 6/7 zones

1 Rad in Conservatory

1 Rad in Utility room

1 Towel rail in bathroom

2 Rads upstairs

Heat sources -

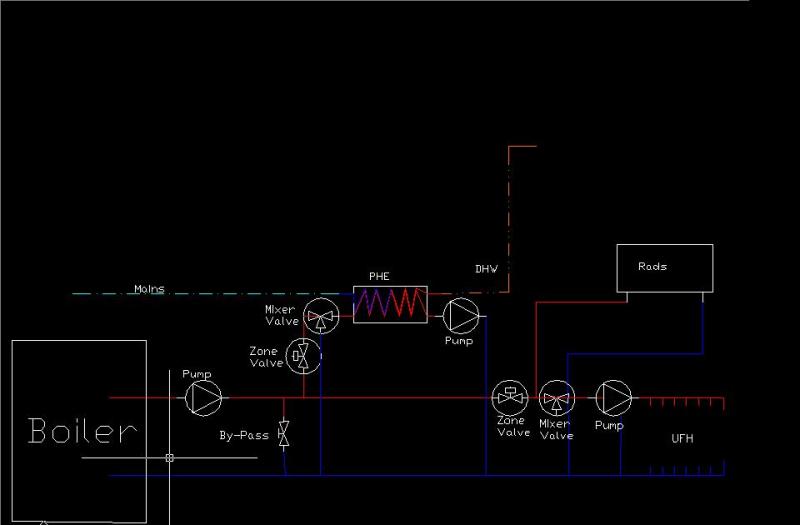

Old oil boiler - will be changed for modern condensing down the line

Would like to utilise back boiler to make a contribution to CH when fire/stove is going

Add solar panel down the line

Given the above desires im looking at a system based around a thermal store to give flexibility and mains pressure DHW.

Planning on using Polypipe 22mm "pipe in pipe" under the insulation so there are no joins under the floor and problems should be easily rectified. Then use distribution manifolds to connect 15/22mm to outlets.

As for the existing copper id like to solder extensions and run them back to a manifold or striaght into the heating circuit if sensible.

Thermal store will be beside the bathoom with the shower being the shortest pipe run and kitchen being the farthest for DHW. Boiler will be about 1m from thermal store but in an exisitng outdoor boiler house. Im hoping by keeping the pipe runs short it should minimise losses and give good response.

So my basic plan of attack is:

Figure out what our main supply pipe is from the water meter, if MDPE trace exisiting copper and replace with MDPE, if not replace the whole thing and have it checked for compliance before filling in and connected by someone qualified.

Run 22mm for the hot/cold water to sensibly located manifolds in kitchen and bathroom

Figure out rad/back boiler circuit

Fit UFH Manifold

fit Insulation and UFH pipework

Fit Thermal store and check it all works before pouring the screed.

Does this sounds right?

Having finally had our sub floors laid we are in a position to start thinking about plumbing. Currently the only pipe work we have is a 15mm copper main through the kitchen wall (giving approx 22l/m), flow and return going to 1 rad in conservatory, pipe work for backboiler and all original pipework in the loft conversion and the old toilet soil pipes

Ive rang quite a few local plumbers but many are too busy (1-3month waits!), dont want a full house to do or dont know anything about thermal store systems

So im thinking of having a go myself

Its a bungalow with 2 rooms upstairs,

Water draws - me + other half, no kids for while

1 bath, 1 shower,1 hand basin,1 toilet, kitchen sink, wash machine.

Heating -

UFH throughout groundfloor, 6/7 zones

1 Rad in Conservatory

1 Rad in Utility room

1 Towel rail in bathroom

2 Rads upstairs

Heat sources -

Old oil boiler - will be changed for modern condensing down the line

Would like to utilise back boiler to make a contribution to CH when fire/stove is going

Add solar panel down the line

Given the above desires im looking at a system based around a thermal store to give flexibility and mains pressure DHW.

Planning on using Polypipe 22mm "pipe in pipe" under the insulation so there are no joins under the floor and problems should be easily rectified. Then use distribution manifolds to connect 15/22mm to outlets.

As for the existing copper id like to solder extensions and run them back to a manifold or striaght into the heating circuit if sensible.

Thermal store will be beside the bathoom with the shower being the shortest pipe run and kitchen being the farthest for DHW. Boiler will be about 1m from thermal store but in an exisitng outdoor boiler house. Im hoping by keeping the pipe runs short it should minimise losses and give good response.

So my basic plan of attack is:

Figure out what our main supply pipe is from the water meter, if MDPE trace exisiting copper and replace with MDPE, if not replace the whole thing and have it checked for compliance before filling in and connected by someone qualified.

Run 22mm for the hot/cold water to sensibly located manifolds in kitchen and bathroom

Figure out rad/back boiler circuit

Fit UFH Manifold

fit Insulation and UFH pipework

Fit Thermal store and check it all works before pouring the screed.

Does this sounds right?