Dear all, I WOULD be VERY GRATEFUL if you could answer the following;

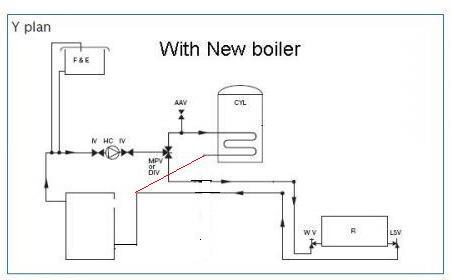

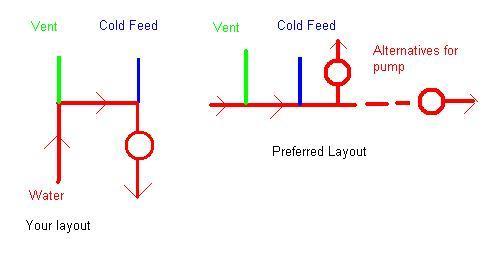

The dotted line (2.) is not in yet, is this ok to run the fill for what is the heating loop (into the HWC and the Rads into the same connection as the cold (-) feed to the boiler/HWC? If this is ok should it run with an offset as close to the HWC as possible as in 14 or is a straight run up ok?

Can I put isolation full bore valves in pipes (2) (14) (13) ? I obviously won't put any valves in the vent pipes to make servicing easier in the future.

I've edited out all the bits that were not answered so anyone looking for info for themselves will get the important stuff!

View media item 51962

The dotted line (2.) is not in yet, is this ok to run the fill for what is the heating loop (into the HWC and the Rads into the same connection as the cold (-) feed to the boiler/HWC? If this is ok should it run with an offset as close to the HWC as possible as in 14 or is a straight run up ok?

Can I put isolation full bore valves in pipes (2) (14) (13) ? I obviously won't put any valves in the vent pipes to make servicing easier in the future.

I've edited out all the bits that were not answered so anyone looking for info for themselves will get the important stuff!

View media item 51962