You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

M

Mickymoody

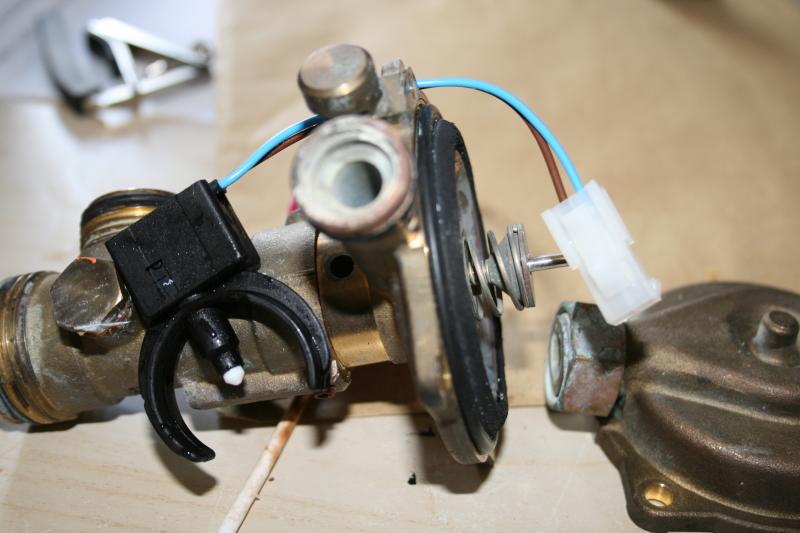

The old diaphramn that has been removed is melted and split, but has a spring still attached, and 2 different sized screws (thats worrying!); We spoke to a different gas engineer today who immediately stated that the 3-way divertor valve is broken, and the engineer that changed the diaphramn probably made the situation worse, and that the diaphramn is capped on the right hand side, and this is where it seems to be leaking from, contrary to what Agile says. And, as when my partner spoke to the guy (so I didn't influence him with my own opinion), stated that the flow switch had probably been refitted incorrectly, hence why the boiler is firing of it's own accord, at random. And was quoted £250 for a possible fix. Money I don't have.

The diaphragm can probably be fitted the wrong way round.

There is a spring that has to be fitted to the right hand side of the diaphragm.

The diaphragm is "cupped" ( not capped ) to hold the spring in place.

The seal between the two brass parts should seal equally well whichever way round the diaphragm is fitted.

I am coming to the conclusion this fellow was a nupty!

Tony

There is a spring that has to be fitted to the right hand side of the diaphragm.

The diaphragm is "cupped" ( not capped ) to hold the spring in place.

The seal between the two brass parts should seal equally well whichever way round the diaphragm is fitted.

I am coming to the conclusion this fellow was a nupty!

Tony

M

Mickymoody

I think I was kind of saying that earlier up in the post Agile, when I compared the diaphramn with a thermostat..?

If a stat in a car is fitted the wrong way round, then it will find the weak link to blow pressure, in my car the bottom rad hose.

Is that because fitting the diaphramn is a PITA to fit? or that it doesn't fix the problem? Lots of bits of rubber running about in the system?

But the thing is, the boiler DOESN'T fire when HW selected. Regardless of all these new faults.

If a stat in a car is fitted the wrong way round, then it will find the weak link to blow pressure, in my car the bottom rad hose.

Is that because fitting the diaphramn is a PITA to fit? or that it doesn't fix the problem? Lots of bits of rubber running about in the system?

But the thing is, the boiler DOESN'T fire when HW selected. Regardless of all these new faults.

The diverter valve needs opening to see which way round the diaphragm has been fitted and where the spring is fitted.

How can an engineer come and replace a part and then walk away when it still does not work?

And more surprising to actually charge for not repairing the boiler?

Tony

How can an engineer come and replace a part and then walk away when it still does not work?

And more surprising to actually charge for not repairing the boiler?

Tony

I think I was kind of saying that earlier up in the post Agile, when I compared the diaphramn with a thermostat..?

If a stat in a car is fitted the wrong way round, then it will find the weak link to blow pressure, in my car the bottom rad hose.

This might be a little confusing, a thermostat on a car looks a little like the diaphragm on this boiler but it's nothitng like it really. The diaphragm doesn't react to temperature, only water pressure.

M

Mickymoody

Sorry Andy, maybe a bad comparison on my part, but the central part of the diaphramn does look kind of thermostat-like to the lay man, ie me...

If the faulty part is holed - as it was, and now it's sealed as it should be, then water is bypassing something that it shouldn't before the part was replaced. Surely that would bleed some hot water to DHW?

The CH works, as it should, it's just that (presumably) the flow switch hasn't been fitted correctly, hence why the boiler comes on of it's own accord, but why leak under that circumstance, but not when CH is selected normally.

This is obviously getting too complicated now.

Agile - You now see my frustrations 4 engineers vs zero faults fixed.

(O/T - My parents have a bath hotwater tap that has seized, they use a shower unit mainly - how to restore flow, the valve inside is locked in solid - if there is no flow to it, and the water is turned off, then surely the water in the system will spurt out if/when the valve removed? As the system can't be bled.)

So I go from a thermistor fault, to a diaphramn, to a 3 way diverter valve fault, explain what a 3 way divertor valve does. And how it works, And what the diaphramn does, can't see how that provides hot water on demand?

I posted the OT question in another section, and the reply included 'it's not human surgery', do people post for fun? or am I asking stupid questions, and getting even worse engineers to repair it?

If the faulty part is holed - as it was, and now it's sealed as it should be, then water is bypassing something that it shouldn't before the part was replaced. Surely that would bleed some hot water to DHW?

The CH works, as it should, it's just that (presumably) the flow switch hasn't been fitted correctly, hence why the boiler comes on of it's own accord, but why leak under that circumstance, but not when CH is selected normally.

This is obviously getting too complicated now.

Agile - You now see my frustrations 4 engineers vs zero faults fixed.

(O/T - My parents have a bath hotwater tap that has seized, they use a shower unit mainly - how to restore flow, the valve inside is locked in solid - if there is no flow to it, and the water is turned off, then surely the water in the system will spurt out if/when the valve removed? As the system can't be bled.)

So I go from a thermistor fault, to a diaphramn, to a 3 way diverter valve fault, explain what a 3 way divertor valve does. And how it works, And what the diaphramn does, can't see how that provides hot water on demand?

I posted the OT question in another section, and the reply included 'it's not human surgery', do people post for fun? or am I asking stupid questions, and getting even worse engineers to repair it?

I am sorry that you have had such a problem with the four engineers.

MOST in our profession do a good job. Sometimes they go wrong usually due to a lack of skills rather then willful neglect.

Very unfortunately there are a few people on forums of all kinds who just use it as an oportunity to be adusive to others. That sometimes gets the forums closed or restricted.

Tony Glazier

MOST in our profession do a good job. Sometimes they go wrong usually due to a lack of skills rather then willful neglect.

Very unfortunately there are a few people on forums of all kinds who just use it as an oportunity to be adusive to others. That sometimes gets the forums closed or restricted.

Tony Glazier

If the faulty part is holed - as it was, and now it's sealed as it should be, then water is bypassing something that it shouldn't before the part was replaced. Surely that would bleed some hot water to DHW?

Hmm Both sides of that diaphragm that'd split was mains water not heating water so they wouldn't mix via the split. But, it's that diaphragm that's responsible for moving the diversion part of the valve between heating/hot water. So if the boiler fired up with a split diaphragm all the heat would go to rads as heating is the open port when in rest position.

I get the feeling you may know this already but i'm not interperated it propperly in what you've said! ha

M

Mickymoody

Cheers Agile - Andy - the diaphramn was melted, and split, and the origional fault was overheat tripping, just on CH, but now no DHW, the CH works as it should. But then randomly turns itself on, and heats the rads, so boiler is off atm. (Due to engineer breaking/misfitting flow switch?)

So back to basics; what would cause the boiler not to fire when DHW selected? flow rate? (associated with the diaphramn?), or even when the thermistors are swapped over and the boiler is running, still no hot water? A defective 3 way valve? I don't want to throw MORE parts at it, or pay for stuff that isn't needed. I worked in the electromechanical business, where electronics are married to mechanical devices.

When thermistors are swapped, boiler fired, tap runs, and pressure goes down?

Now when CH is run, pressure drops to 1 bar, which is too low.

I'm trying to provide you guys with the correct info..it works fine on CH, then drops pressure, then turns itself on, then leaks...argh!

The engineer hasn't been back in touch, said they would look at Ravenheat website (what cause they sell them, but don't support them?)

Guess I'm just unlucky.

So back to basics; what would cause the boiler not to fire when DHW selected? flow rate? (associated with the diaphramn?), or even when the thermistors are swapped over and the boiler is running, still no hot water? A defective 3 way valve? I don't want to throw MORE parts at it, or pay for stuff that isn't needed. I worked in the electromechanical business, where electronics are married to mechanical devices.

When thermistors are swapped, boiler fired, tap runs, and pressure goes down?

Now when CH is run, pressure drops to 1 bar, which is too low.

I'm trying to provide you guys with the correct info..it works fine on CH, then drops pressure, then turns itself on, then leaks...argh!

The engineer hasn't been back in touch, said they would look at Ravenheat website (what cause they sell them, but don't support them?)

Guess I'm just unlucky.

Confused....!

Did you say the hot water works ok if the thermistors are swapped?

What parts has it had so far?

Did you say the hot water works ok if the thermistors are swapped?

What parts has it had so far?

M

Mickymoody

The thread is getting too lengthy to make sense.

No hot water regardless of replacement parts ever.

Thermistors swapped, works as per. CH OK, no HW

Flow switch bypassed, boiler free runs, rads get hot, domestic hot water cold.

Running the hot water tap in this situation means that the water pressure in the boiler reduces at the same rate as water flow from the tap.

Parts replaced - clip on thermistor, diaphramn. £45.

Two engineers - £45 down, the boiler now leaks.

The boiler does NOT fire when hot water requested.

No hot water regardless of replacement parts ever.

Thermistors swapped, works as per. CH OK, no HW

Flow switch bypassed, boiler free runs, rads get hot, domestic hot water cold.

Running the hot water tap in this situation means that the water pressure in the boiler reduces at the same rate as water flow from the tap.

Parts replaced - clip on thermistor, diaphramn. £45.

Two engineers - £45 down, the boiler now leaks.

The boiler does NOT fire when hot water requested.

Running the hot water tap in this situation means that the water pressure in the boiler reduces at the same rate as water flow from the tap

The water coming out of the tap doesn't have any influence on the water pressure indicated on the gauge. Well, not directly anyway. When the pump starts it will pull the gauge down a bit due to the negative pressure.

If the boiler doesn't fire when running the tap but it does fire when you bypass the flow switch, there must be some kind of issue with the diverter pin not making the switch on it's own (this is controled by the diaphragm you've changed) If you remove the microswitch from the end of the diverter can you see the pin extend fully?

When you run the tap with the flowswitch bypassed do you get hot water?

M

Mickymoody

Running the hot water tap in this situation means that the water pressure in the boiler reduces at the same rate as water flow from the tap

The water coming out of the tap doesn't have any influence on the water pressure indicated on the gauge. Well, not directly anyway. When the pump starts it will pull the gauge down a bit due to the negative pressure.

In fault condition/flow switch bypassed yes it does. The pressure goes down in relation to the HW (that is cold) flow.

If the boiler doesn't fire when running the tap but it does fire when you bypass the flow switch, there must be some kind of issue with the diverter pin not making the switch on it's own (this is controled by the diaphragm you've changed) If you remove the microswitch from the end of the diverter can you see the pin extend fully?

There is no visible microswitch attached to the end of the 3 way valve, that would be pressed by the diaphramn pin. The only microswitch in the area around the 3 way valve is the flow switch on top of the 3 way valve.

When you run the tap with the flowswitch bypassed do you get hot water?

No

To confirm, there is NO microswitch attached anywhere near the diaphramn, there is nothing broken, snapped, removed, loose, dislodged or displaced in that area. This is a Ravenheat LS80 boiler. There is no mention of such a switch in the manual, nor any diagram or part reference to such a switch that I am aware of in the manual, or physically fitted inside the boiler. Can someone post a picture of said microswitch, because the lack of it certainly seems to have some bearing as to the fault!

I did risk running the boiler on CH today, and it worked on CH (no hot water), but everything was shut down and switched off for safety afterwards.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 0

- Views

- 861

- Replies

- 8

- Views

- 2K

- Replies

- 12

- Views

- 1K

- Replies

- 8

- Views

- 2K

- Replies

- 26

- Views

- 7K