Hello All,

Can anyone help please?

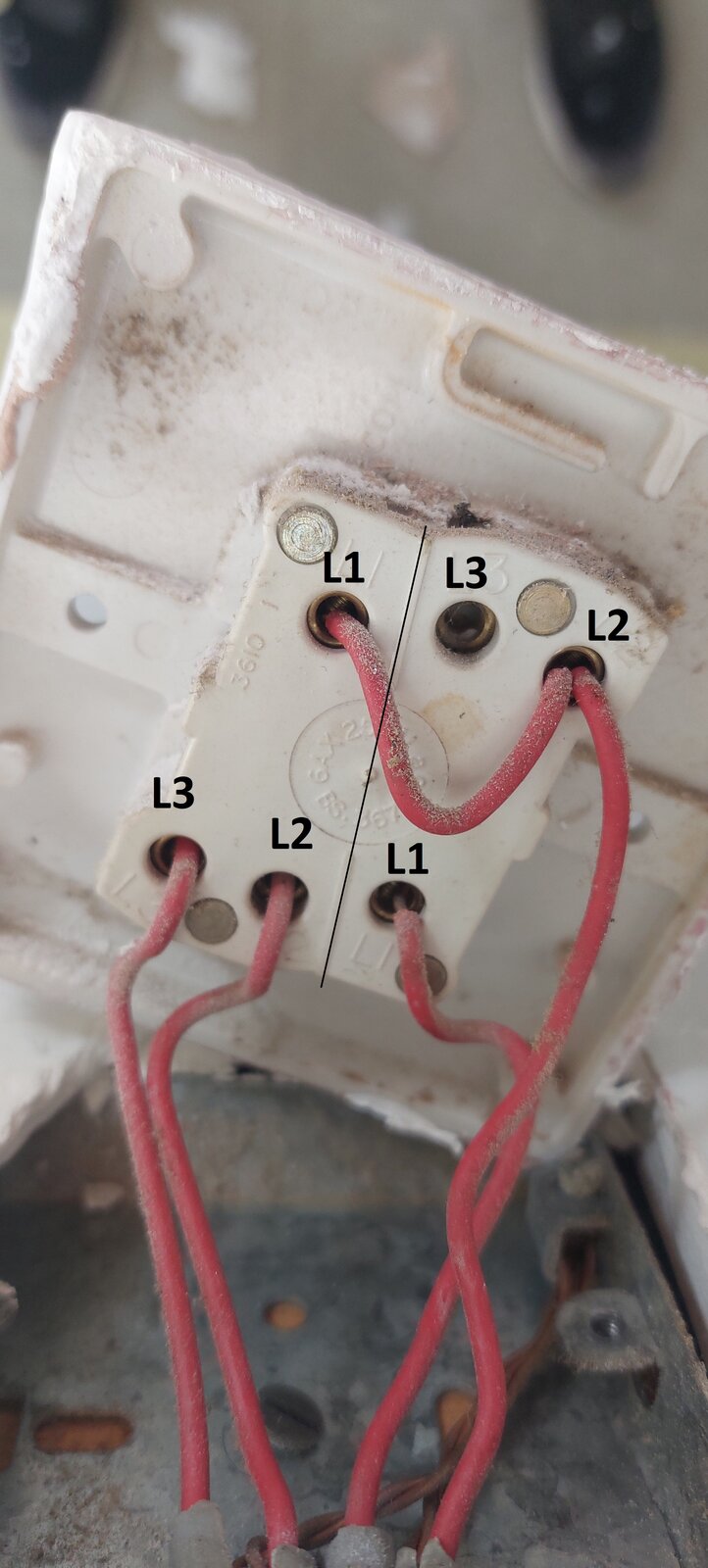

I am trying to replace this old Crabtree double light switch.

The left hand side looking at the image controls the ceiling light. This light can also be turned on/off from a light switch at the other end of the room. The right hand side in the image controls a wall lamp.

This is the new double 2 way switch I have bought (MK)

How should I wire this please?

Thank you in advance

Can anyone help please?

I am trying to replace this old Crabtree double light switch.

The left hand side looking at the image controls the ceiling light. This light can also be turned on/off from a light switch at the other end of the room. The right hand side in the image controls a wall lamp.

This is the new double 2 way switch I have bought (MK)

How should I wire this please?

Thank you in advance

Last edited: