You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Short cycling until flow temperature reached - error 2967

- Thread starter Ccw71

- Start date

Does the boiler need to be running at 100% of it set maximum output, in my case 22kw for that flow rate calculation? The WB 8000 has a modulation ratio of 10:1, so does that mean in lowest tickover it's outputting about 2.5kw?

If so, using the calculation you supplied, would that then make my boilers current flow rate to be around 2.15 Lpm?

I hope I'm totally wrong though!

If so, using the calculation you supplied, would that then make my boilers current flow rate to be around 2.15 Lpm?

I hope I'm totally wrong though!

You have it set (RANGE RATED) to 55% max which means that it's max output can't go higher than 55% of 40kw = 22kw, it may e vent be lower as the max output of that boiler may be 36kw to CH & 40kw to DHW.Does the boiler need to be running at 100% of it set maximum output, in my case 22kw for that flow rate calculation? The WB 8000 has a modulation ratio of 10:1, so does that mean in lowest tickover it's outputting about 2.5kw?

If so, using the calculation you supplied, would that then make my boilers current flow rate to be around 2.15 Lpm?

I hope I'm totally wrong though!

You don't need to keep reducing it now anyway as you can read off the flow from the pump, very handy info when trouble shooting any problem

.

Last edited:

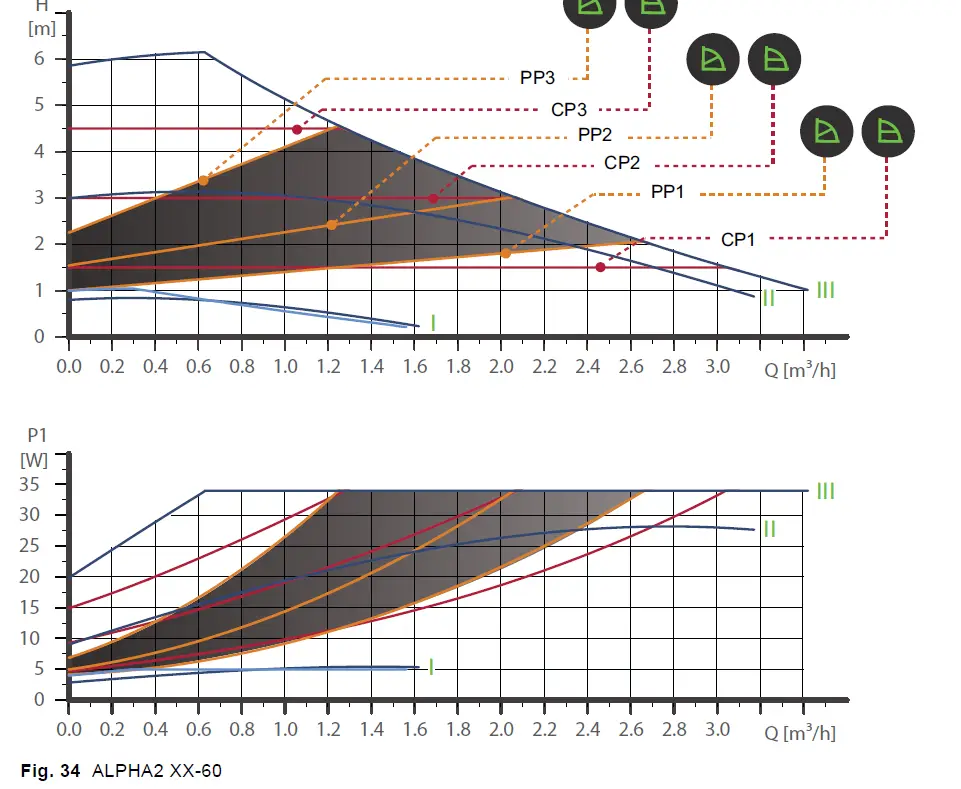

Can you post a photo of, or/and the exact model of Alpha 2 pump.

If its the 6M one and it is running in CC3 then the flow rate is only ~ 0.35m3/hr or 5.8LPM, no good, not enough.

The boiler output, based on your dT of 15.7C and my flow of 5.8LPM is 5.8X60X15.7/860, 6.35kw.

A 10:1 modulation = min output of 3.6/4.0kw, quite good for a 40kw boiler.

If its the 6M one and it is running in CC3 then the flow rate is only ~ 0.35m3/hr or 5.8LPM, no good, not enough.

The boiler output, based on your dT of 15.7C and my flow of 5.8LPM is 5.8X60X15.7/860, 6.35kw.

A 10:1 modulation = min output of 3.6/4.0kw, quite good for a 40kw boiler.

Last edited:

The WB 8000 has a modulation ratio of 10:1, so does that mean in lowest tickover it's outputting about 2.5kw?

There was a really interesting thread a couple of days ago about range rating and modulation. If I understood correctly, the modulation ratio applies to the maximum output. I think your model actually has an 8:1 modulation ratio; the 30 KW and 35 KW have 10:1. So, that would mean your boiler would go down to 5 KW.

The challenge with all gas boilers, no matter how good the modulation is, is that they fire up with ignitions conditions set to 60 to 70% of max output, some then take 60 secs or so, (Vaillant are "notorious" for this) to modulate down, so requires a reasonably high flow rate to get away without exceeding the SP flowtemp+5C and burner trip + recycle. Range rating will not range rate the ignition settings of 60/70%. What can also help is to have a decent anticycle time as the circ pump remains running and will get the boiler temp well down if the anticycle time is, say, 5 minutes.

Last edited:

The pump is actually an Alpha 1. It will only show power on the display, so I've been trying to make sense of this, but it's way beyond me.

Attachments

Sorry to butt in, but I think earlier you said you now have it on CP3, and I think it was suggested to use CC3. Don't know if that would alter the calculation.The pump is actually an Alpha 1. It will only show power on the display, so I've been trying to make sense of this, but it's way beyond me.

This is your lefthand graph, above.

You will see power in W on the vertical axis, and the flowrate in m3.hr on the bottom horizontal axis, you know that the pump power is 28watts so draw a line horizontally to the right from 28 until it intercepts the Constant curve III, (your setting) then drop down vertically to the bottom horizontal axis and you will see that the flow is 0.41m3/hr = 6.83LPM, very poor for a pump that is running at a 6M head. Your flow rate should be at least 12LPM so problems?.

You will see power in W on the vertical axis, and the flowrate in m3.hr on the bottom horizontal axis, you know that the pump power is 28watts so draw a line horizontally to the right from 28 until it intercepts the Constant curve III, (your setting) then drop down vertically to the bottom horizontal axis and you will see that the flow is 0.41m3/hr = 6.83LPM, very poor for a pump that is running at a 6M head. Your flow rate should be at least 12LPM so problems?.

I think our posts crossed. I think the pump might now be set to CP3, not CC3, according to a post a little while back. If that is right, it would seem to explain the discrepancy.This is your lefthand graph, above.

You will see power in W on the vertical axis, and the flowrate in m3.hr on the bottom horizontal axis, you know that the pump power is 28watts so draw a line horizontally to the right from 28 until it intercepts the Constant curve III, (your setting) then drop down vertically to the bottom horizontal axis and you will see that the flow is 0.41m3/hr = 6.83LPM, very poor for a pump that is running at a 6M head. Your flow rate should be at least 12LPM so problems?.

"I ran it up to a steady flow temp of 64.5 where it's been sat for about an hour. All TRVS open with thr rads balanced to heat up about equally. Room temp is around 19-20. The boiler has modulated down to what sounds like minimum and the return temp is sitting around 48.8. The pump is running on CP3 as you recomended, 28 (watts?) on the screen."

Well spotted Jonathan, this makes a huge difference, gives a flow rate of 0.95m3/hr, 15.9LPM @ 4.5M head on CP3, that's more like it and if correct, quite acceptable, CC3 should give ~ 15.98*sqroot (6/4.5) = 18.45LPM & ~ 35W so lets see.I think our posts crossed. I think the pump might now be set to CP3, not CC3, according to a post a little while back. If that is right, it would seem to explain the discrepancy.

"I ran it up to a steady flow temp of 64.5 where it's been sat for about an hour. All TRVS open with thr rads balanced to heat up about equally. Room temp is around 19-20. The boiler has modulated down to what sounds like minimum and the return temp is sitting around 48.8. The pump is running on CP3 as you recomended, 28 (watts?) on the screen."

Last edited:

Can you post a picture of your pump + the LED settings (present) so everyone is absolutely sure that the flow rate is as it now appears to be, perfectly satisfactory, and more so if on CC3.The pump is actually an Alpha 1. It will only show power on the display, so I've been trying to make sense of this, but it's way beyond me.

Actually, originally. I misread your setting as PP2, it was CP2, which should have given a flowrate of 15.98*sqroot(3/4.5),

12.9LPM @ a 3M head.

Last edited:

All last year it was set on PP2 and ran about 7-9W. It was running on CP3 earlier when the measurements were taken, though at this speed it seems to draw air through the vent pipe (a different issue to be resolved later) so I later turned it down a bit to CP2 (17W) for a few hours testing. Photo as it was when the temps were recorded.

Am I mixing up the CC and CP.... appologies.

Am I mixing up the CC and CP.... appologies.

Attachments

Last edited:

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 19

- Views

- 15K

- Replies

- 4

- Views

- 3K

- Replies

- 12

- Views

- 11K

- Replies

- 15

- Views

- 5K