Hi all, I'm fitting a big fat aluminium 3.4kW radiator. It's on the end of a very long system, which is piped 35, 22 and then 15mm for the last 5m. The old two radiators it's replacing barely got enough flow, until I fitted a big pump and turned it up so the system was a bit noisy. So now, after nursing the pipe ends and joints, using bends and 45 degree joints instead of elbows, all that, to optimised the flow, I'm looking at a standard 15mm TRV valve and it looks very constrictive! What do you think? Should I be looking for something hi-flow? Or will it do, do you think, once my lovingly cherished flow arrives?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Standard TRV, flow for a big radiator?

- Thread starter Nigel R

- Start date

A 15mm TRV or lock shield valve has, I think, a valve coefficient (Cv) of 1 which means it will flow 1m3/hr @ a 1bar dP, there will be a TRV + a lockshield valve in series so this results in a flowrate of 0.707m3/hr @ 1bar dP or in circ pump terms, 2.64LPM at a dP of 1M. If you assume that the minimum dT you need is 15C at full rad output then that 3.4kw rad will require a flowrate of 3.25LPM which means a dP of 1.5M, maybe add another 0.2M for rad loss so 1.7M, say 2M total dP?.

- Joined

- 27 Jan 2008

- Messages

- 28,129

- Reaction score

- 3,411

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

In the main radiators at the end of the run stop working as they should because the earlier radiators have not been set correctly.

Thanks, I know what you mean. However I have balanced the system with the old rads. There are 24 rads (I think) and the boiler is in the annex!In the main radiators at the end of the run stop working as they should because the earlier radiators have not been set correctly.

Thanks for this awesome reply. What would you think would be a normal kind of dP? And yes I take your later point two rads would have two sets of valves.A 15mm TRV or lock shield valve has, I think, a valve coefficient (Cv) of 1 which means it will flow 1m3/hr @ a 1bar dP, there will be a TRV + a lockshield valve in series so this results in a flowrate of 0.707m3/hr @ 1bar dP or in circ pump terms, 2.64LPM at a dP of 1M. If you assume that the minimum dT you need is 15C at full rad output then that 3.4kw rad will require a flowrate of 3.25LPM which means a dP of 1.5M, maybe add another 0.2M for rad loss so 1.7M, say 2M total dP?.

Depends on rad capacity, if one used a 1.5kw rad as a "average" then the dP through the valves would be only ~ 0.3M, I have never seen numbers for the dP through a rad but imagine it would be quite small so maybe total dP of 0.5/0.75M.

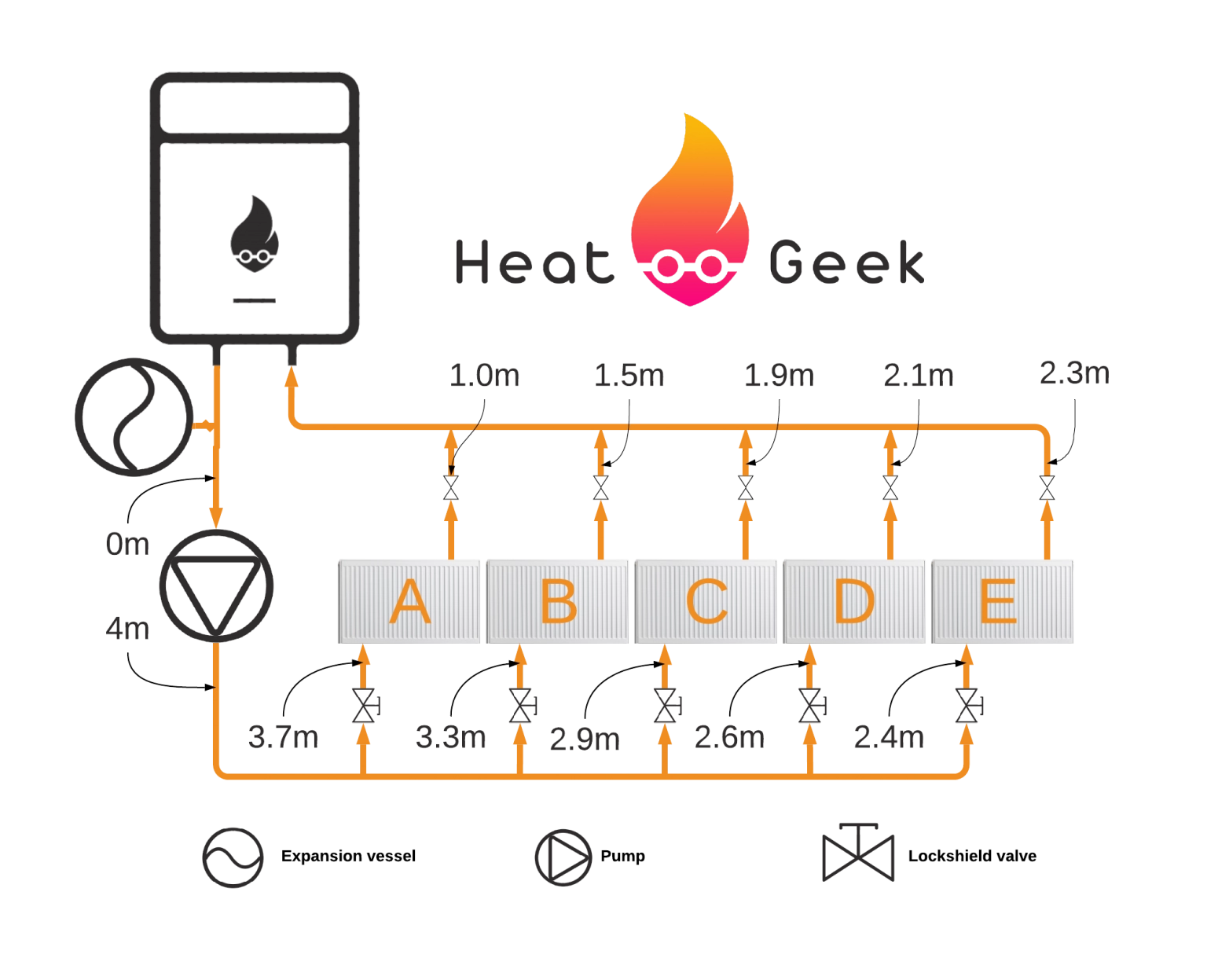

Heat Geek gives a nice picture here of (non) balancing where A=very high flow. B=high flow. C=correct flow D=low flow. E= way too low flow., I would assume all rads same size, possibly 1.5kw?.

Heat Geek gives a nice picture here of (non) balancing where A=very high flow. B=high flow. C=correct flow D=low flow. E= way too low flow., I would assume all rads same size, possibly 1.5kw?.

Last edited:

Thanks, what's the unit M you're using?Depends on rad capacity, if one used a 1.5kw rad as a "average" then the dP through the valves would be only ~ 0.3M, I have never seen numbers for the dP through a rad but imagine it would be quite small so maybe total dP of 0.5/0.75M.

Meters, all circ pumps are quoted in meters, the normal might be considered as 6meters, 6M, increasingly now, A rated pumps are rated something like 4.5/6.5M, 8M pumps are sometimes used in very large installations or are used to overcome incorrectly sized pipe sizes, the pump must give the required flowrate and requires a head high enough to overcome all losses, ie pipe friction losses, valve losses, boiler heat exchanger losses etc.

Ah, thanks. So 2M equates to about 0.2 bar, in your earlier calculation. I asked Grundfos what they'd recommend and so I've now got a mother of pumps that, so far, I haven't turned up above 2 out of 5Meters, all circ pumps are quoted in meters, the normal might be considered as 6meters, 6M, increasingly now, A rated pumps are rated something like 4.5/6.5M, 8M pumps are sometimes used in very large installations or are used to overcome incorrectly sized pipe sizes, the pump must give the required flowrate and requires a head high enough to overcome all losses, ie pipe friction losses, valve losses, boiler heat exchanger losses etc.

It's a Magna 32-100. On a 35mm pipeWhat is the pump model ?.

- Joined

- 27 Jan 2008

- Messages

- 28,129

- Reaction score

- 3,411

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

My 3.5 kW radiator had no TRV or lock shield valve, just two isolation valves, it use 12 mm pipes and worked A1 but the instructions I think said 15 mm pipes, and output was controlled by the speed of the fan and turning the fan on/off. A very small physical size radiator but high output.

But this was before the condensing or modulating boiler, the return water when fan was not running was nearly as hot as the feed.

In my mothers house I had a problem both over and under heating, my setting of the lock shield valve with having no differential thermometer was to turn the lock shield off, then ¼ turn at a time until feed pipe just a little warm. This seemed to improve things, but the major problem was the bay window, when the sun hit the window the temperature of the room would sore. So I got first a pair, and then some more electronic TRV heads, it was actually not the speed that helped but the fact on the PC I got a report current and target. this allowed me to see at a glance which radiators were allowing too much flow, and those with too little, clearly if the current exceeded the target then the lock shield needed closing, and this was the case with most of the radiators.

this allowed me to see at a glance which radiators were allowing too much flow, and those with too little, clearly if the current exceeded the target then the lock shield needed closing, and this was the case with most of the radiators.

And TRV be it electronic or mechanical takes time to open and close, typically the electronic when they exercise mid day Saturday every week take around 3.5 minutes to fully open, fully close, and return to setting, so a radiator should take at least 15 minutes to warm up, likely longer, to give the TRV's time to adjust. And all mine were open too wide, and as I adjusted them I found the TRV's were spot on, set to 20ºC I actually got 20ºC, the problem before was the TRV was marked *123456 which is a little useless when trying to set two things, once the lock shield was set the old mechanical worked well, but it was the setting of two devices which caused the problem.

The second problem was the wall thermostat, never really understood why it is there with a modern modulating boiler, I suppose to stop cycling, but if it turns off then no heat to any room, so the instructions say fit it in a room normally kept cool, on the lower floor, with no outside doors, and no alternative heating, well in the main the room does not exist, so you need to have a TRV's either linked to the wall thermostat, or a TRV in the same room set to turn off heating before the wall thermostat set temperature, unless it's a warm day.

This is not as easy as it seems, on a warm day the TRV and wall thermostat show the same temperature but on a cold day, with the wall thermostat being set higher on the wall to what a TRV is, it will show up to 2ºC higher than the TRV in my house, I think main problem is also TRV nearer to door and wall thermostat nearer centre of house, but as soon as the wall thermostat turns off the whole system of TRV and by pass valve clearly stops working.

We realised in my house the patio door in dining room was causing much of the problem, it cooled the wall between in and the hall, so cooling the wall where the TRV on hall radiator is. We have all these clever ideas of heating rooms only when required using programmable TRV's but our internal walls ceilings and floors are not well insulated, so heat transfers room to room idea of turning a room fully off does not really work.

However a sequence of heating does work, so when heating starts first the kitchen, then dinning room, then living room and finally bedroom means the kitchen heats up faster, not too much time gap or the boiler will turn off or down, but the sequence does result in faster recovery of rooms.

What I noticed once set was radiators were only just warm, the rooms were to temperature, so radiator turns down, which means by pass opens and hot water returned to boiler, and so boiler modulates, as it should, so radiators never either cold or hot, they just stay warm, reducing the hysteresis as the TRV should.

But all my lock shield valves were open too much, and only found out once I could monitor temperatures on the PC.

But this was before the condensing or modulating boiler, the return water when fan was not running was nearly as hot as the feed.

In my mothers house I had a problem both over and under heating, my setting of the lock shield valve with having no differential thermometer was to turn the lock shield off, then ¼ turn at a time until feed pipe just a little warm. This seemed to improve things, but the major problem was the bay window, when the sun hit the window the temperature of the room would sore. So I got first a pair, and then some more electronic TRV heads, it was actually not the speed that helped but the fact on the PC I got a report current and target.

this allowed me to see at a glance which radiators were allowing too much flow, and those with too little, clearly if the current exceeded the target then the lock shield needed closing, and this was the case with most of the radiators.

this allowed me to see at a glance which radiators were allowing too much flow, and those with too little, clearly if the current exceeded the target then the lock shield needed closing, and this was the case with most of the radiators.And TRV be it electronic or mechanical takes time to open and close, typically the electronic when they exercise mid day Saturday every week take around 3.5 minutes to fully open, fully close, and return to setting, so a radiator should take at least 15 minutes to warm up, likely longer, to give the TRV's time to adjust. And all mine were open too wide, and as I adjusted them I found the TRV's were spot on, set to 20ºC I actually got 20ºC, the problem before was the TRV was marked *123456 which is a little useless when trying to set two things, once the lock shield was set the old mechanical worked well, but it was the setting of two devices which caused the problem.

The second problem was the wall thermostat, never really understood why it is there with a modern modulating boiler, I suppose to stop cycling, but if it turns off then no heat to any room, so the instructions say fit it in a room normally kept cool, on the lower floor, with no outside doors, and no alternative heating, well in the main the room does not exist, so you need to have a TRV's either linked to the wall thermostat, or a TRV in the same room set to turn off heating before the wall thermostat set temperature, unless it's a warm day.

This is not as easy as it seems, on a warm day the TRV and wall thermostat show the same temperature but on a cold day, with the wall thermostat being set higher on the wall to what a TRV is, it will show up to 2ºC higher than the TRV in my house, I think main problem is also TRV nearer to door and wall thermostat nearer centre of house, but as soon as the wall thermostat turns off the whole system of TRV and by pass valve clearly stops working.

We realised in my house the patio door in dining room was causing much of the problem, it cooled the wall between in and the hall, so cooling the wall where the TRV on hall radiator is. We have all these clever ideas of heating rooms only when required using programmable TRV's but our internal walls ceilings and floors are not well insulated, so heat transfers room to room idea of turning a room fully off does not really work.

However a sequence of heating does work, so when heating starts first the kitchen, then dinning room, then living room and finally bedroom means the kitchen heats up faster, not too much time gap or the boiler will turn off or down, but the sequence does result in faster recovery of rooms.

What I noticed once set was radiators were only just warm, the rooms were to temperature, so radiator turns down, which means by pass opens and hot water returned to boiler, and so boiler modulates, as it should, so radiators never either cold or hot, they just stay warm, reducing the hysteresis as the TRV should.

But all my lock shield valves were open too much, and only found out once I could monitor temperatures on the PC.

That's encouraging Eric, thanks. Interesting system you have and we have trodden quite a similar path, with a modulating boiler and smart TRVs. Balancing as you say has been a long running exercise.

When we moved in all the lockshields were just open 1 turn, bit of a disgrace! 2 boilers each with a standard built-in pump... the system simply didn't work.

Last winter on the new boiler and controls we used 52% of the gas of the year before, so heading in a good direction, and this new rad has insulation behind it now instead of brick

When we moved in all the lockshields were just open 1 turn, bit of a disgrace! 2 boilers each with a standard built-in pump... the system simply didn't work.

Last winter on the new boiler and controls we used 52% of the gas of the year before, so heading in a good direction, and this new rad has insulation behind it now instead of brick

That's a massive pump alright, you say "I haven't turned up above 2 out of 5" what does this mean?, I can't find a detailed description of your pump modes, have you any link?.It's a Magna 32-100. On a 35mm pipe

Have you now got one boiler serving the 24 rads, any idea of their total kw output?

Edit: Found one link which shows a setting of 1 to 10.

Does your pump display the pump head M and the flow in M3/hr?,

Last edited:

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 7

- Views

- 3K

- Replies

- 3

- Views

- 10K

- Replies

- 9

- Views

- 24K

- Replies

- 9

- Views

- 10K