Good morning,

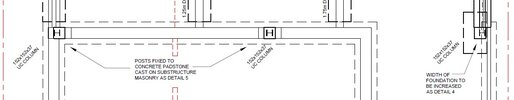

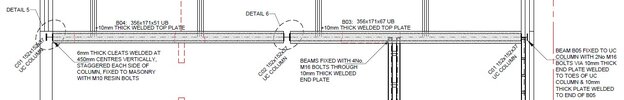

I am managing an extension on my own house and trying to pin down my chosen steel fabricator to call out and measure up is proving difficult! With that in mind I am looking at confirming the measurements and placing the order. The structural engineer has provided lengths for the beams (B04 and B03 on the below) but not the column height. B03 and B04 have been designed to pickup the 1st floor cavity wall at the rear of the house allowing the ground floor to be knocked through into the extension.

The extension roof will be a warm flat roof constructed out of 47*225 joists.

B03 and B04 are to be sunk into the ceiling void to allow a flush ceiling from the existing room into the extension. To ensure its right how would you measure the universal column height based on the below images? I have exposed the underside of the 1st floor joists and also broken out the screed, but if I am interpreting the drawings correctly I also need to break out the concrete slab and then measure from the underside of the slab to the underside of the existing joists, does that sound correct?

What tolerances should I allow in terms of the column height, i.e. would it be better to be 10mm higher than 10mm too low? I will be chasing up the fabricator today to see if I can get him to visit regardless,

Thanks

I am managing an extension on my own house and trying to pin down my chosen steel fabricator to call out and measure up is proving difficult! With that in mind I am looking at confirming the measurements and placing the order. The structural engineer has provided lengths for the beams (B04 and B03 on the below) but not the column height. B03 and B04 have been designed to pickup the 1st floor cavity wall at the rear of the house allowing the ground floor to be knocked through into the extension.

The extension roof will be a warm flat roof constructed out of 47*225 joists.

B03 and B04 are to be sunk into the ceiling void to allow a flush ceiling from the existing room into the extension. To ensure its right how would you measure the universal column height based on the below images? I have exposed the underside of the 1st floor joists and also broken out the screed, but if I am interpreting the drawings correctly I also need to break out the concrete slab and then measure from the underside of the slab to the underside of the existing joists, does that sound correct?

What tolerances should I allow in terms of the column height, i.e. would it be better to be 10mm higher than 10mm too low? I will be chasing up the fabricator today to see if I can get him to visit regardless,

Thanks