After ordering the timber a few months ago i have managed to get a week off work and want to get the sub floor down to release the UFH.

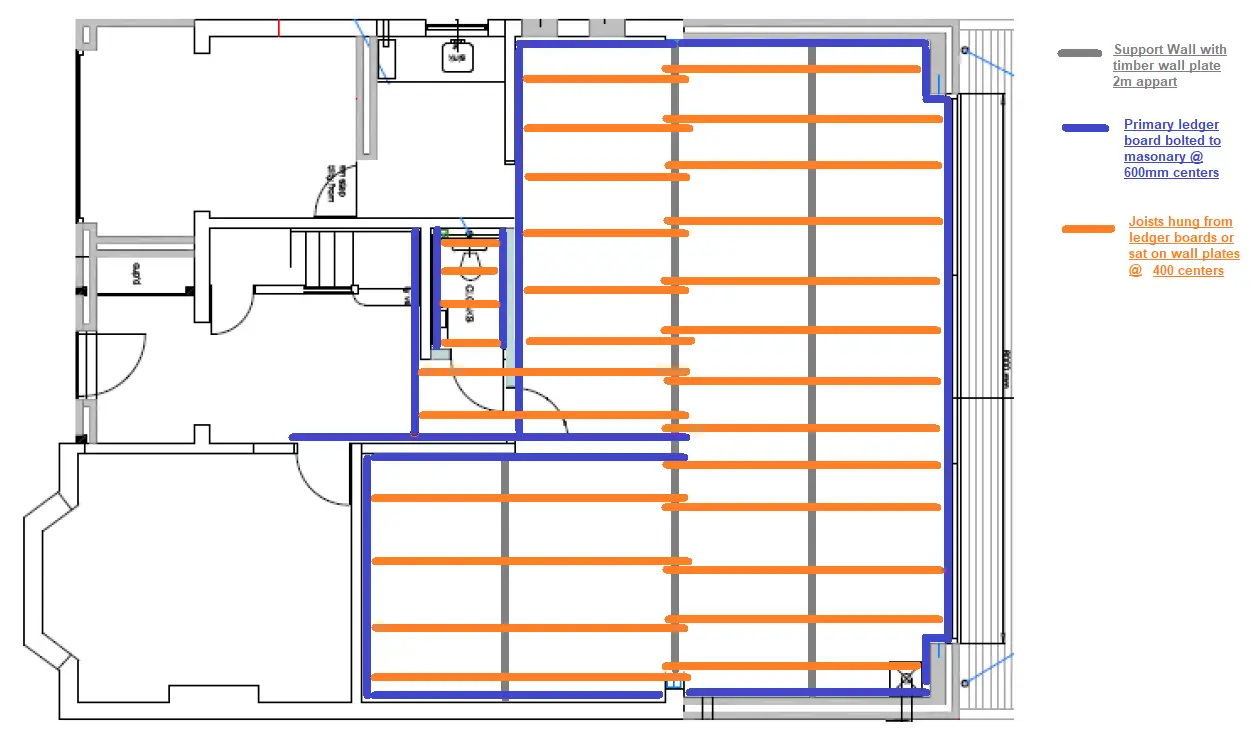

I plan to install perimeter timbers to all external walls fixed with M12 studs @ 600mm centers chem fixed into masonry.

I have dwarf supporting walls at each 2m span with timber wall plates bedded onto them.

Joists are to be spaced at 400mm centers, hung from hangers on the ledger boards and sat and nailed to the wall plates on supporting walls with 2 noggins for every 2m span.

Firstly is the above the correct methodology?

My questions are;

1) Is there a position to start from? Do you start at one side a move across or start from the center and work outwards?

2) Is 2 noggins per 2m span (1 mid span and 1 at supporting wall location) suficient?

3) The floor structure above will be 22mm chipboard grooved for the UFH pipework with a 6mm ply on top. Will this need noggins at each sheet joint?

I plan to install perimeter timbers to all external walls fixed with M12 studs @ 600mm centers chem fixed into masonry.

I have dwarf supporting walls at each 2m span with timber wall plates bedded onto them.

Joists are to be spaced at 400mm centers, hung from hangers on the ledger boards and sat and nailed to the wall plates on supporting walls with 2 noggins for every 2m span.

Firstly is the above the correct methodology?

My questions are;

1) Is there a position to start from? Do you start at one side a move across or start from the center and work outwards?

2) Is 2 noggins per 2m span (1 mid span and 1 at supporting wall location) suficient?

3) The floor structure above will be 22mm chipboard grooved for the UFH pipework with a 6mm ply on top. Will this need noggins at each sheet joint?