Hi

I bought an ACV SLE 240 tank believing from their website that it would have multiple connections (the plus model) and having found a cracking deal. Well, as ever if it's cheap there is a reason: these were clearance units and were not the plus version (and are no longer sold) - only coming with 2 ports to the primary (external) tank.

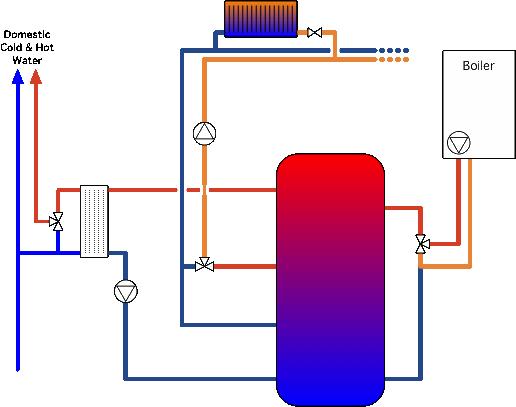

My original plan was simple: I use more heating at night and less hot water. I use less heating in the morning but lots of hot water. Being a tank in tank I had two independent volumes of water and a lot of energy that could be used in different ways. one set of ports with pumped boiler feed, another set of ports for out and return to rads. That way the energy from the primary could be used towards the radiators and the secondary energy would also help heat the primary. The boiler being independent kicks in to keep the cylinder hot enough. Caveat: I am no pro so this is all theoretical and I am aware that people generally have massive tanks to do this so don't expect huge benefit.

Now I only have two ports to the primary tank it seems I have limited options: 1) send the cylinder back and pay through the nose for what I wanted in the first place 2) use the boiler and 3 port valve as per the suggested layout to heat either cylinder or rads (which I guess doesn't give me what I want) 3) concoct some cunning plan. And it's this last option that I'd like some help with.

As you can tell I am no expert - and I am no doubt going to be told so in no uncertain terms. The only thing I came up with was a two pump set-up which on second thoughts I'm not convinced works. I've added a picture to my gallery but I'm afraid I don't know how to link to that. Looking at the scribble version - if the boiler pump moved to the other side of the rad connection and ran marginally slower.... I am tying myself in knots - can anyone help, or am I rally going to have to bite the bullet and return the tank?

Many thanks

Pete

I bought an ACV SLE 240 tank believing from their website that it would have multiple connections (the plus model) and having found a cracking deal. Well, as ever if it's cheap there is a reason: these were clearance units and were not the plus version (and are no longer sold) - only coming with 2 ports to the primary (external) tank.

My original plan was simple: I use more heating at night and less hot water. I use less heating in the morning but lots of hot water. Being a tank in tank I had two independent volumes of water and a lot of energy that could be used in different ways. one set of ports with pumped boiler feed, another set of ports for out and return to rads. That way the energy from the primary could be used towards the radiators and the secondary energy would also help heat the primary. The boiler being independent kicks in to keep the cylinder hot enough. Caveat: I am no pro so this is all theoretical and I am aware that people generally have massive tanks to do this so don't expect huge benefit.

Now I only have two ports to the primary tank it seems I have limited options: 1) send the cylinder back and pay through the nose for what I wanted in the first place 2) use the boiler and 3 port valve as per the suggested layout to heat either cylinder or rads (which I guess doesn't give me what I want) 3) concoct some cunning plan. And it's this last option that I'd like some help with.

As you can tell I am no expert - and I am no doubt going to be told so in no uncertain terms. The only thing I came up with was a two pump set-up which on second thoughts I'm not convinced works. I've added a picture to my gallery but I'm afraid I don't know how to link to that. Looking at the scribble version - if the boiler pump moved to the other side of the rad connection and ran marginally slower.... I am tying myself in knots - can anyone help, or am I rally going to have to bite the bullet and return the tank?

Many thanks

Pete