- Joined

- 17 Sep 2023

- Messages

- 12

- Reaction score

- 0

- Country

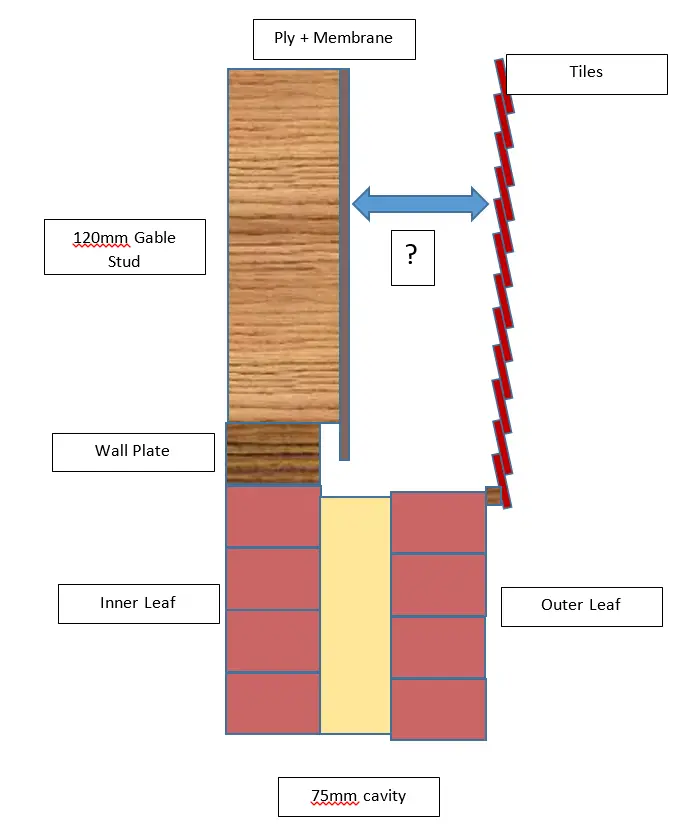

Planning a hip-to-gable and need some advice please. The gable will be timber framed and have vertical hung tiles. SE says it must be supported off the inner leaf - it's taking load from a ridge beam.

I'm using 120mm timber for the studwork. This leaves some 150mm gap from the finished gable face, across the cavity & external leaf to tiles.

Battens / counter battens will take up 50mm or so. Any suggestions how this gap should be bridged? Or perhaps I've really misunderstood something - happy to be put right!

Cheers!

I'm using 120mm timber for the studwork. This leaves some 150mm gap from the finished gable face, across the cavity & external leaf to tiles.

Battens / counter battens will take up 50mm or so. Any suggestions how this gap should be bridged? Or perhaps I've really misunderstood something - happy to be put right!

Cheers!