Hi all,

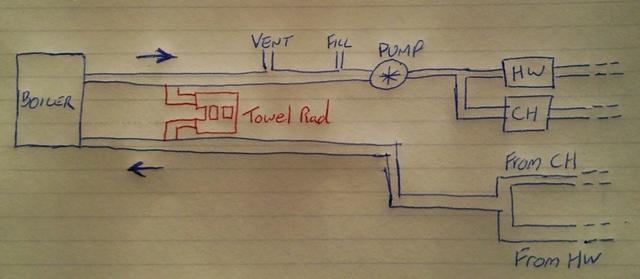

I just wanted to make sure that the following plumbing plan will work for a bathroom towel radiator that needs to be on whenever the boiler is running, irrelevant of whether it is doing Hot Water or Central Heating.

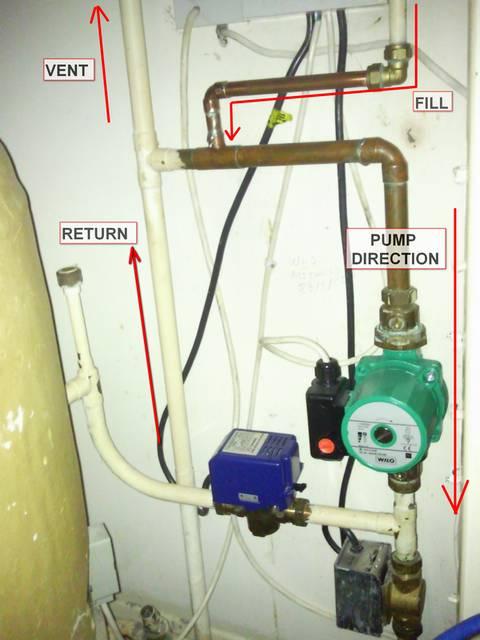

My system is indirect heating vented system with pumped primary;

The system as it was is the blue sections, and the red section is where the plumber has tied in the bathroom towel radiator. He mad the connections whilst I was refitting the bathroom and the new connections are now under the bath leading to 2 capped pipes ready for me to connect the towel rail to.

However since reading a bit on here, I'm not sure if the feed to the towel rail, (the top red pipe), should come AFTER the pump and before the valves?

I can see why it has been done the way it has, as it meant the plumber could do all the work in the bathroom rather than having to run fresh pipework back to the airing cupboard.

I just want to make sure it will work ok before connect up the rail and board over the section of floor.

I'm hoping that as long as I close down the balancing valve on the towel rail to the right point water will still flow through the boiler and the towel rail....

Just after some second opinions please

I just wanted to make sure that the following plumbing plan will work for a bathroom towel radiator that needs to be on whenever the boiler is running, irrelevant of whether it is doing Hot Water or Central Heating.

My system is indirect heating vented system with pumped primary;

The system as it was is the blue sections, and the red section is where the plumber has tied in the bathroom towel radiator. He mad the connections whilst I was refitting the bathroom and the new connections are now under the bath leading to 2 capped pipes ready for me to connect the towel rail to.

However since reading a bit on here, I'm not sure if the feed to the towel rail, (the top red pipe), should come AFTER the pump and before the valves?

I can see why it has been done the way it has, as it meant the plumber could do all the work in the bathroom rather than having to run fresh pipework back to the airing cupboard.

I just want to make sure it will work ok before connect up the rail and board over the section of floor.

I'm hoping that as long as I close down the balancing valve on the towel rail to the right point water will still flow through the boiler and the towel rail....

Just after some second opinions please